A muffle furnace is used for "burning" in a highly controlled, scientific sense, not for simple combustion. This process is most accurately called ashing, where a sample is heated at a high temperature to burn away all its organic components, leaving only the non-combustible inorganic residue. This is a common analytical technique used across various industries to determine the composition of materials.

A muffle furnace is not for setting things on fire, but for precisely transforming them with heat. Its core function is to heat materials to extreme temperatures in an isolated chamber, which prevents contamination and ensures uniform heat. This allows for processes far beyond simple burning, including altering chemical structures and strengthening metals.

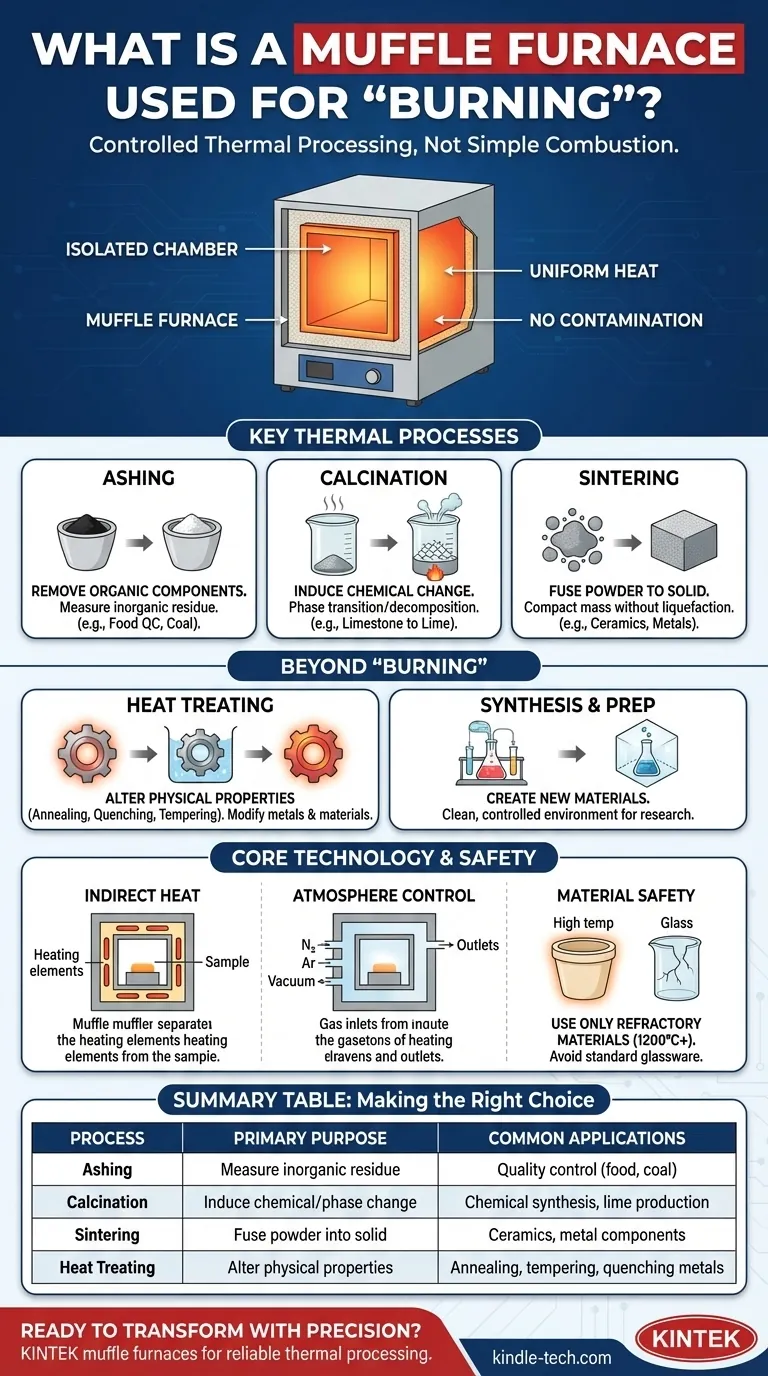

The Key Thermal Processes Involved

When we talk about "burning" in a muffle furnace, we are typically referring to one of several specific high-temperature processes. Each has a distinct purpose.

Ashing: To Determine Inorganic Content

Ashing is the most direct answer to the question of "burning." It is a process of thermal decomposition that completely removes volatile and organic substances from a sample.

The goal is to accurately measure the weight of the remaining inorganic material, or ash. This is a critical step in quality control and analysis for coal, environmental samples, and food products.

Calcination: To Induce Chemical Change

Calcination involves heating a solid material to a high temperature to cause a phase transition or thermal decomposition.

Unlike ashing, the goal isn't just to burn material away, but to change its chemical state. A common example is heating limestone (calcium carbonate) to produce lime (calcium oxide) for industrial use.

Sintering: To Fuse Materials Together

Sintering uses heat to compact and form a solid mass of material from a powder without melting it to the point of liquefaction.

This process is fundamental in creating ceramic parts, fabricating metallic components, and in materials science research. The furnace provides the stable, high-temperature environment needed for particles to bond together.

Beyond "Burning": The Furnace as a Tool for Transformation

A muffle furnace's utility extends far beyond decomposition. It is a cornerstone for modifying and synthesizing materials.

Heat Treating Metals and Materials

The furnace provides the precise temperature control needed for metallurgical processes that alter the physical properties of metals. These include:

- Annealing: Heating and then slowly cooling to make a metal less brittle and more workable.

- Quenching: Rapidly cooling a metal after heating to increase its hardness.

- Tempering: Reheating a quenched metal to a lower temperature to reduce brittleness while maintaining hardness.

These same principles apply to processing ceramics, glass, and even semiconductors.

Synthesis and Sample Preparation

In scientific research and pharmaceuticals, a muffle furnace is used to synthesize new materials or prepare samples for further analysis.

The clean, controlled environment ensures that the results are due to the intended process, not outside contamination. This is vital for drug testing and developing new chemical compounds.

Understanding the Trade-offs and Core Technology

The value of a muffle furnace lies in its design, but that design comes with specific considerations.

The Principle of Indirect Heat

The defining feature of a muffle furnace is the "muffle"—an insulating chamber that separates the material being heated from the heating elements.

This indirect heating is crucial. It prevents contamination from the combustion byproducts or elements themselves and provides a highly uniform temperature, ensuring consistent and repeatable results.

Atmosphere Control is a Key Variable

Basic muffle furnaces operate by heating a sample in the presence of ambient air. This is sufficient for simple ashing or calcination.

However, more advanced models allow for atmosphere control. This means the chamber can be filled with a specific gas (like nitrogen or argon) or held in a vacuum. This is essential for processes where reactions with oxygen must be prevented.

Material and Safety Limitations

Muffle furnaces reach extremely high temperatures, often exceeding 1200°C (2192°F).

Only refractory laboratory materials, such as specific types of ceramic or high-temperature metal crucibles, can be safely placed inside. Using standard glassware or plastics would result in immediate failure and potential damage to the furnace.

Making the Right Choice for Your Goal

The term "burning" in a muffle furnace can mean many things. The specific process you need depends entirely on your objective.

- If your primary focus is determining a sample's composition: You are performing ashing to precisely measure the inorganic residue.

- If your primary focus is changing a material's chemical structure: You need calcination to drive thermal decomposition or a phase change.

- If your primary focus is improving a metal's physical properties: You will be using heat-treating processes like annealing or tempering.

- If your primary focus is creating a solid object from powder: The process you require is sintering, common in ceramics and metallurgy.

Ultimately, a muffle furnace gives you the power to transform materials with precise and controlled heat.

Summary Table:

| Process | Primary Purpose | Common Applications |

|---|---|---|

| Ashing | Burn away organic material to measure inorganic residue | Quality control for food, coal, environmental samples |

| Calcination | Induce thermal decomposition or phase change | Producing lime from limestone, chemical synthesis |

| Sintering | Fuse powder particles into a solid mass | Manufacturing ceramics, metallic components |

| Heat Treating | Alter physical properties of metals | Annealing, tempering, and quenching metals |

Ready to transform your materials with precision? A KINTEK muffle furnace provides the controlled, high-temperature environment essential for accurate ashing, calcination, sintering, and heat treatment. Our lab equipment is designed for reliability and repeatability, ensuring your analytical and synthesis processes are a success. Contact us today to find the perfect solution for your laboratory's thermal processing needs. Get in touch via our contact form!

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the construction of a muffle furnace? A Deep Dive into Its Core Systems

- What is the principle working and use of muffle furnace? Achieve Precise, Contamination-Free Heating

- What are the precautions of muffle furnace? Essential Safety Protocols for Your Lab

- What is the main purpose of a furnace? A Guide to Heating, Comfort, and Material Transformation

- What are muffle furnaces used for? Achieve Precise, Contaminant-Free High-Temperature Processing