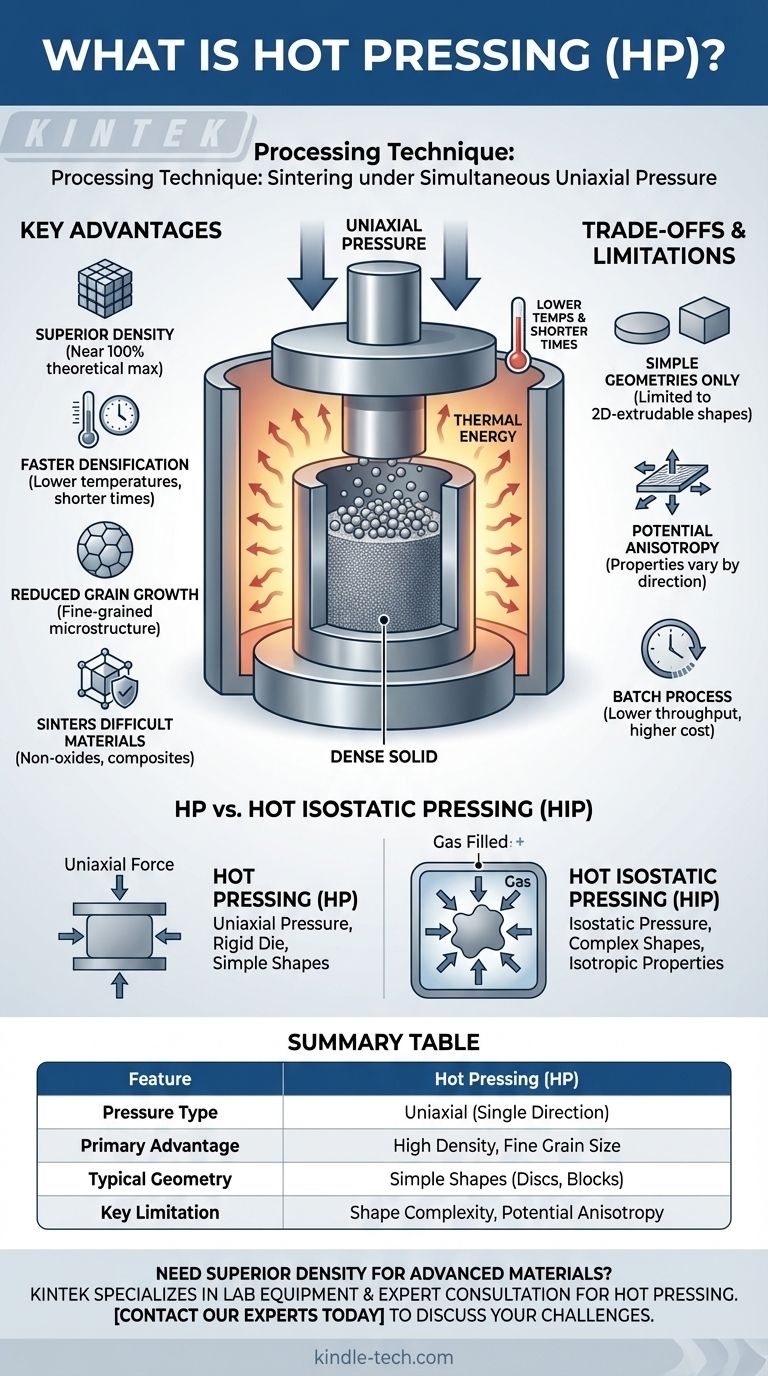

The processing technique in which sintering is conducted under simultaneous uniaxial pressure is known as Hot Pressing (HP). It is a powder metallurgy process designed to consolidate powders into a dense solid by applying heat and a directional force at the same time, significantly enhancing the densification process compared to pressureless sintering.

Hot Pressing is a specialized consolidation method used to achieve near-full density and fine-grained microstructures in high-performance materials that are otherwise difficult to sinter. It leverages uniaxial pressure to accelerate densification, but this comes with fundamental trade-offs in component geometry and potential property directionality.

How Hot Pressing Works

The Core Principle: Heat and Force

In Hot Pressing, a powder is loaded into a die cavity, which is typically made of graphite or a ceramic composite. The entire assembly is heated in a furnace while rams or punches apply a strong, compressive force along a single axis (uniaxially).

This combination of thermal energy and mechanical pressure is the defining characteristic of the process.

Accelerating Densification

The applied pressure dramatically aids the sintering process. It increases the contact stress between powder particles, which promotes material transport mechanisms like diffusion and plastic flow.

This allows for full densification at significantly lower temperatures and for shorter times than would be required in conventional, pressureless sintering.

The Role of the Die

The rigid die is essential for containing the powder and transmitting the uniaxial force. The final shape of the component is dictated entirely by the shape of the die cavity.

Because the consolidated part must be ejected from the die, Hot Pressing is fundamentally limited to producing simple geometries like discs, blocks, and cylinders.

Key Advantages Over Other Methods

Superior Density and Properties

The primary advantage of Hot Pressing is its ability to produce materials with very high density, often approaching 100% of the material's theoretical maximum.

This lack of porosity, combined with the fine grain size preserved by using lower temperatures, results in materials with superior mechanical properties, such as high strength, hardness, and fracture toughness.

Sintering Difficult Materials

Hot Pressing is indispensable for materials that are inherently difficult to densify. This includes many non-oxide ceramics (like silicon carbide and boron nitride), composites, and covalently bonded materials that show poor diffusion in conventional sintering.

Reduced Grain Growth

By enabling densification at lower temperatures, Hot Pressing effectively inhibits grain growth. A fine-grained microstructure is often critical for achieving high performance in structural ceramics and other advanced materials.

Understanding the Trade-offs and Limitations

Shape and Size Restrictions

The most significant limitation of Hot Pressing is its inability to form complex shapes. The process is restricted to simple, 2D-extrudable geometries that allow for part ejection from the die.

Hot Pressing vs. Hot Isostatic Pressing (HIP)

It is crucial not to confuse Hot Pressing (HP) with Hot Isostatic Pressing (HIP). While HP uses uniaxial pressure in a rigid die, HIP uses isostatic (uniform, all-directional) gas pressure to consolidate parts.

HIP can produce highly complex, near-net-shape components and results in fully isotropic properties, but it is often a more complex and expensive process.

Potential for Anisotropy

Because the pressure is applied in a single direction, the resulting microstructure can become textured or aligned. This can lead to anisotropy, where the material's properties (e.g., strength, thermal conductivity) are different when measured parallel versus perpendicular to the pressing direction.

Process Cost and Throughput

Hot Pressing is a batch process with relatively low throughput compared to industrial methods like press-and-sinter. The equipment is specialized, and the dies (especially graphite) have a limited life, adding to the overall cost.

Making the Right Choice for Your Goal

Selecting the correct sintering method depends entirely on your material, desired properties, and component requirements.

- If your primary focus is achieving maximum density and fine grain size in a difficult-to-sinter material with a simple shape: Hot Pressing is an ideal and powerful choice.

- If your goal is to produce a dense, complex-shaped component with uniform properties in all directions: You should investigate Hot Isostatic Pressing (HIP).

- If you are mass-producing simple metal or ceramic parts where cost is a major driver and some porosity is acceptable: Conventional pressureless sintering or press-and-sinter remains the industry standard.

By understanding the unique interplay of uniaxial pressure and temperature, you can effectively leverage Hot Pressing to engineer advanced materials that would otherwise be impossible to create.

Summary Table:

| Feature | Hot Pressing (HP) |

|---|---|

| Pressure Type | Uniaxial (Single Direction) |

| Primary Advantage | High Density, Fine Grain Size |

| Typical Geometry | Simple Shapes (Discs, Blocks) |

| Key Limitation | Shape Complexity, Potential Anisotropy |

Need to achieve superior density and performance for your advanced materials?

KINTEK specializes in providing the precise lab equipment and expert consultation needed for processes like Hot Pressing. Whether you are developing new ceramics, composites, or other high-performance materials, our solutions help you optimize your sintering process for maximum results.

Contact our experts today to discuss how we can support your laboratory's specific material science challenges.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the advantages of using a vacuum hot press for CuCr50? Achieve Superior Density & Purity in Alloy Production

- What are the advantages of using a vacuum hot press sintering furnace? Achieve 99.1% Density in CuW30 Composites

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes

- What role does a high-temperature hot press play in the sintering of NITE-SiC? Optimize Your Densification Process

- What conditions does a Vacuum Hot Pressing Furnace provide for Copper-MoS2-Mo composites? Achieve Peak Densification