At its core, Physical Vapor Deposition (PVD) is a vacuum-based process used to apply an exceptionally thin film of material onto a surface. The technique works by turning a solid source material into a vapor, which then travels through a vacuum and condenses onto the target object, building the coating atom by atom. This entire process is a physical one, meaning the fundamental chemistry of the coating material does not change.

The central concept of PVD is simple: moving a material from a source to a substrate without altering its chemical identity. It is a three-stage physical transformation from solid to vapor and back to a solid film, all conducted in a high-vacuum environment.

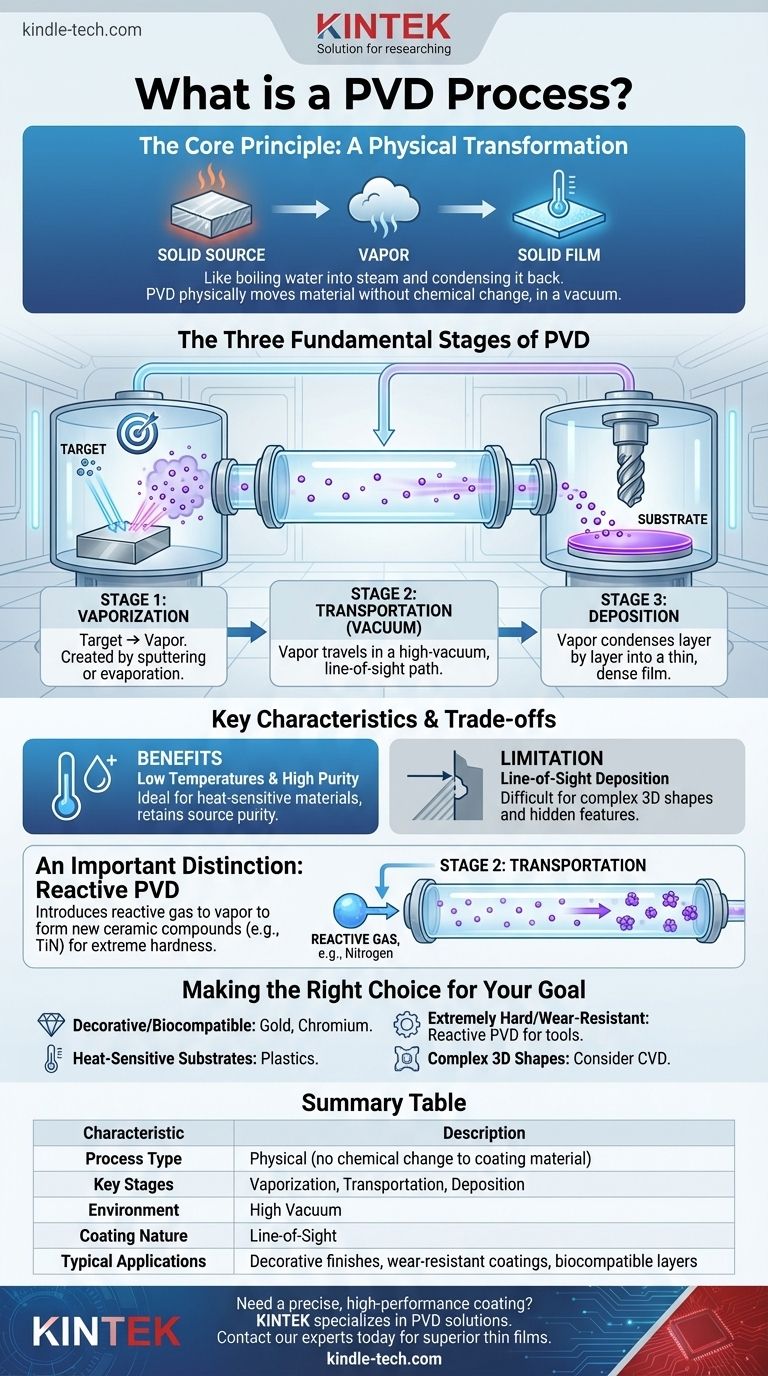

The Core Principle: A Physical Transformation

The most intuitive way to understand PVD is to think of water vapor. When you boil water, it turns into steam (a gas). When that steam hits a cold mirror, it condenses back into a liquid (or solid frost if the mirror is cold enough).

PVD operates on this exact same principle, but with materials like titanium, gold, or ceramic compounds. The process physically moves material, not chemically creates it. This is the key differentiator from other methods like Chemical Vapor Deposition (CVD).

The Three Fundamental Stages of PVD

Every PVD process, regardless of the specific technology used, follows a clear, three-step sequence. This occurs inside a chamber where the air has been removed to create a high vacuum.

Stage 1: Vaporization (Creating the "Cloud")

First, the solid source material, known as the target, must be converted into a vapor. This is accomplished by bombarding it with a high-energy source.

Common methods include thermal evaporation, where the material is heated until it vaporizes, or sputtering, where the target is bombarded with high-energy ions (a plasma), knocking atoms loose.

Stage 2: Transportation (The Journey in a Vacuum)

Once the atoms are vaporized, they travel from the target toward the object being coated (the substrate).

This journey must happen in a vacuum to prevent the vaporized atoms from colliding with air molecules. The vacuum ensures a clean, direct, "line-of-sight" path from the target to the substrate.

Stage 3: Deposition (Condensing into a Film)

When the vapor cloud of material reaches the comparatively cool substrate, it condenses and turns back into a solid.

This deposition happens layer by layer, often atom by atom, resulting in a very thin, dense, and highly uniform film across the substrate's surface.

Understanding the Key Characteristics and Trade-offs

PVD is chosen for specific reasons, and it's essential to understand its advantages and limitations.

The Benefit: Low Temperatures and High Purity

Because PVD is a physical transfer process, it can be performed at relatively low temperatures. This makes it ideal for coating heat-sensitive materials, such as plastics or certain alloys, that would be damaged by high-temperature chemical processes.

Furthermore, since no chemical reactions are involved, the deposited film retains the high purity of the original source material.

The Limitation: "Line-of-Sight" Deposition

The most significant trade-off of PVD is its "line-of-sight" nature. The vaporized atoms travel in straight lines, meaning they can only coat surfaces they can "see" from the source.

This makes it difficult to uniformly coat complex, three-dimensional shapes with internal surfaces or hidden features. Objects often need to be rotated on complex fixtures to ensure even coverage.

An Important Distinction: Reactive PVD

While standard PVD involves no chemical changes, a common variation is Reactive PVD. In this method, a reactive gas (like nitrogen or oxygen) is intentionally introduced into the vacuum chamber.

This gas reacts with the vaporized metal atoms to form a new compound—such as titanium nitride—which is then deposited on the substrate. This allows for the creation of extremely hard and durable ceramic coatings.

Making the Right Choice for Your Goal

PVD is not a one-size-fits-all solution. Its suitability depends entirely on the desired outcome for the final product.

- If your primary focus is a high-purity, decorative, or biocompatible finish: PVD is an excellent choice for applying materials like gold, chromium, or titanium without altering their properties.

- If your primary focus is coating a heat-sensitive substrate: The relatively low temperature of the PVD process makes it superior to many other methods for materials like plastics.

- If your primary focus is creating an extremely hard, wear-resistant coating: Reactive PVD is the industry standard for creating ceramic films on items like cutting tools and industrial components.

- If your primary focus is coating a highly complex 3D shape uniformly: You must carefully consider the line-of-sight limitations and may need to investigate alternative processes like CVD.

Ultimately, PVD is a precise surface engineering tool for depositing high-performance films under tightly controlled conditions.

Summary Table:

| PVD Characteristic | Description |

|---|---|

| Process Type | Physical (no chemical change to coating material) |

| Key Stages | Vaporization, Transportation, Deposition |

| Environment | High Vacuum |

| Coating Nature | Line-of-Sight |

| Typical Applications | Decorative finishes, wear-resistant coatings, biocompatible layers |

Need a precise, high-performance coating for your components?

KINTEK specializes in advanced lab equipment and consumables for surface engineering. Whether you are developing new products or optimizing a coating process, our PVD solutions and expertise can help you achieve superior thin films with excellent adhesion and purity.

Contact our experts today to discuss how we can support your laboratory's specific coating challenges and goals.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications