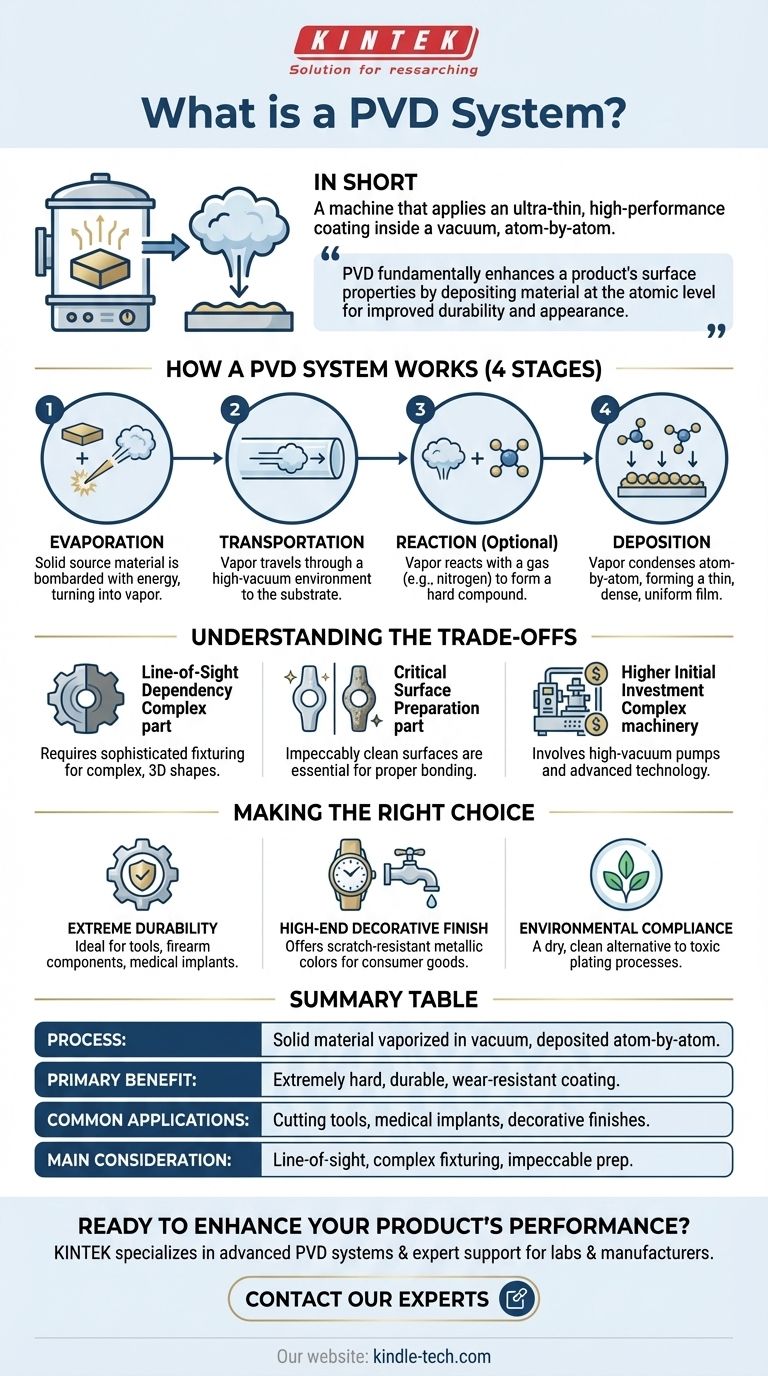

In short, a PVD system is a machine that applies an ultra-thin, high-performance coating to a product inside a vacuum chamber. PVD, which stands for Physical Vapor Deposition, is not a simple painting or plating process; it involves turning a solid material into a vapor, which then condenses atom-by-atom onto a target surface to form a new, incredibly durable layer.

PVD is best understood as a materials science process that fundamentally enhances a product's surface properties. By depositing material at the atomic level, a PVD system can dramatically improve durability, wear resistance, and appearance without altering the core structure of the underlying component.

How a PVD System Works

At its core, a PVD system is a sophisticated vacuum chamber designed to meticulously control the transfer of material from a source to a substrate. The entire process can be broken down into four distinct stages.

1. Evaporation: Creating the Vapor

The process begins with a solid source material, often a high-purity metal or ceramic. Inside the vacuum, this source material is bombarded with high energy, typically from a plasma arc or an electron beam. This energy is intense enough to convert the solid directly into a vapor, creating a cloud of individual atoms or molecules.

2. Transportation: Moving Through a Vacuum

This vaporized material then travels from its source toward the objects being coated. This journey happens within a high-vacuum environment, which is critical. The vacuum removes air and other particles that would otherwise interfere with or contaminate the vapor, ensuring a pure, unimpeded path to the target.

3. Reaction: Forming a New Compound (Optional)

In many applications, a reactive gas like nitrogen, oxygen, or methane is precisely introduced into the chamber. The vaporized metal atoms react with this gas mid-flight to form a new, extremely hard ceramic compound, such as titanium nitride (a gold-colored coating) or chromium nitride.

4. Deposition: Building the Atomic Film

Finally, the vaporized atoms or newly formed compound molecules strike the target object. Upon impact, they condense back into a solid state, building a thin, dense, and highly-adherent film. Because this happens atom by atom, the resulting coating is exceptionally uniform and strongly bonded to the surface.

Understanding the Trade-offs

While powerful, PVD is a specific tool with its own set of technical considerations. It is not a universal solution for all coating challenges.

Line-of-Sight Dependency

The vaporized material travels in a straight line. This means that surfaces not directly exposed to the vapor source will not get coated. Coating complex, three-dimensional shapes or internal bores requires sophisticated fixtures that rotate and reposition the parts during the process.

Critical Surface Preparation

The success of PVD is entirely dependent on the cleanliness of the substrate. The parts must be impeccably clean, free of any oils, dust, or oxides. Improper cleaning is the most common cause of coating failure, as it prevents the film from bonding correctly to the surface.

Higher Initial Investment

PVD systems are complex and require significant capital investment compared to older methods like wet electroplating. The machinery involves high-vacuum pumps, advanced power supplies, and computerized process controls, making it a more technologically demanding operation.

Making the Right Choice for Your Goal

PVD is chosen when the performance of the surface is as critical as the part itself. Consider your primary objective to determine if it is the correct approach.

- If your primary focus is extreme durability and wear resistance: PVD is the superior choice for applications like cutting tools, firearm components, and medical implants where surface hardness is paramount.

- If your primary focus is a high-end decorative finish: PVD provides a vast palette of metallic colors with far greater scratch resistance than paint or traditional plating, making it ideal for watches, faucets, and consumer electronics.

- If your primary focus is environmental compliance: PVD is a dry, clean alternative to processes like chrome plating, completely avoiding the toxic chemicals and hazardous waste associated with wet plating.

Ultimately, a PVD system provides a powerful tool for fundamentally re-engineering the surface of a material to meet demanding performance requirements.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | A solid material is vaporized in a vacuum and deposited atom-by-atom onto a target surface. |

| Primary Benefit | Creates an extremely hard, durable, and wear-resistant coating that bonds strongly to the substrate. |

| Common Applications | Cutting tools, medical implants, consumer electronics, automotive components, and decorative finishes. |

| Main Consideration | A line-of-sight process requiring complex fixturing for 3D parts and impeccable surface preparation. |

Ready to enhance your product's performance with a superior PVD coating?

KINTEK specializes in providing advanced PVD systems and expert support for laboratories and manufacturers. Our equipment is designed to deliver the durable, high-quality finishes your applications demand, from cutting tools to medical devices.

Contact our experts today via our simple form to discuss how a KINTEK PVD system can solve your coating challenges and add value to your products.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What is the main function of hot press forming? Achieve Superior Strength & Precision in Manufacturing

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts

- What is vacuum lamination? Achieve a Flawless, Durable Finish on Complex Shapes