In the laboratory, a roller mixer is a specialized instrument for the gentle yet thorough mixing of fluids. It is primarily used for biological samples like blood, liquid-solid suspensions, and viscous substances where preventing aeration (the introduction of air bubbles) and preserving sample integrity are critical.

The core value of a roller mixer is its unique ability to provide continuous, end-over-end agitation. This gentle motion ensures a homogenous mixture without the high-shear forces or foaming that would damage sensitive cells or compromise experimental results.

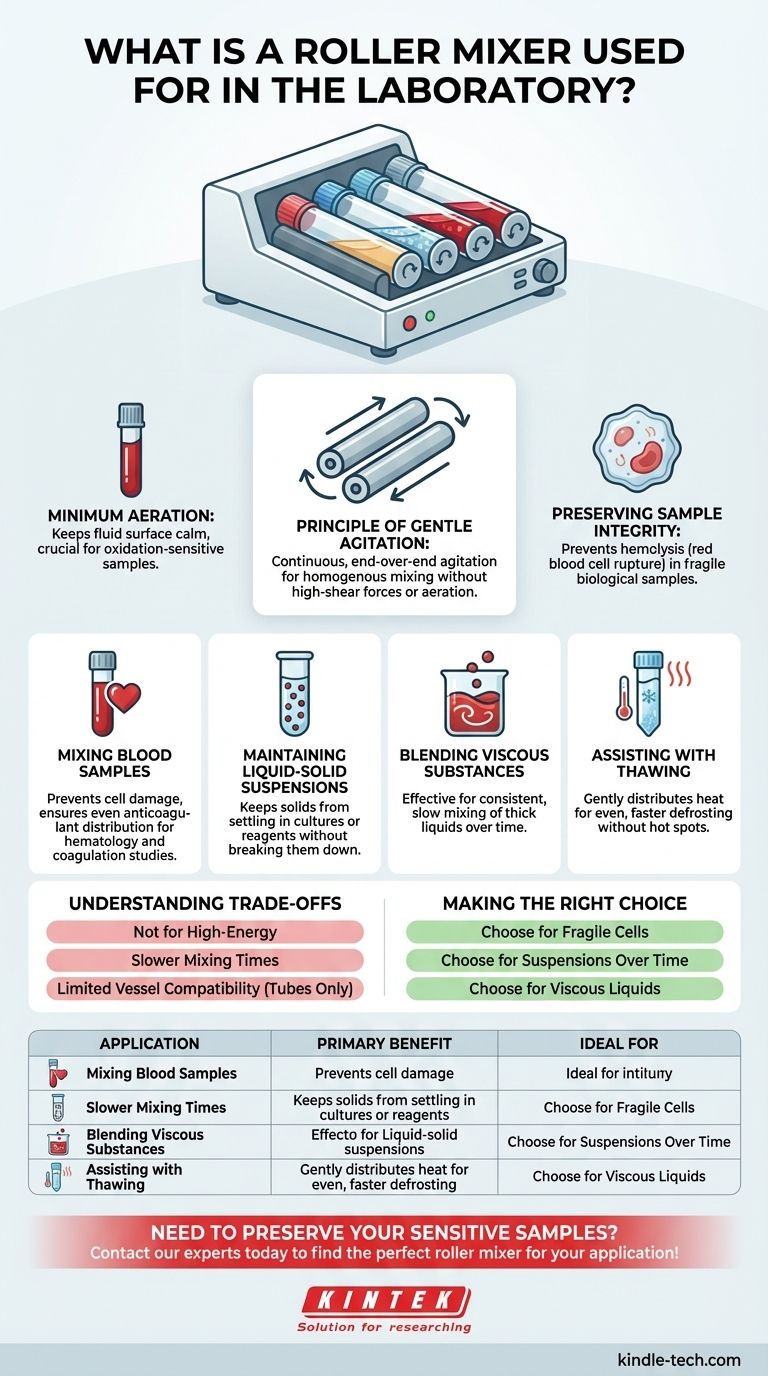

The Principle of Gentle Agitation

A roller mixer's design is simple but highly effective. It consists of a set of parallel rollers that slowly rotate. When tubes are placed on these rollers, they are gently and continuously turned, creating a mixing action that is both consistent and non-disruptive.

How It Works: Rolling and Tilting

The tubes are placed horizontally across the rollers. As the rollers turn, they simultaneously rotate the tube along its long axis while also gently tilting it up and down.

This dual-motion action ensures the entire volume of the sample is constantly in motion, preventing solids from settling and ensuring liquids are thoroughly combined.

The Core Benefit: Minimum Aeration

Unlike vortex mixers or shakers that create a violent vortex and introduce significant amounts of air, the smooth action of a roller mixer keeps the fluid surface relatively calm.

This is crucial for applications where foam can interfere with analysis or where the sample components are sensitive to oxidation.

Preserving Sample Integrity

The gentle rolling action is ideal for fragile biological samples. For instance, aggressive shaking can cause hemolysis—the rupture of red blood cells. A roller mixer prevents this, ensuring blood samples remain viable for accurate analysis.

Key Laboratory Applications

The unique mixing style of a roller mixer makes it the preferred tool for several specific tasks where other mixers would be unsuitable.

Mixing Blood Samples

This is the most common application. Roller mixers are used to keep anticoagulants evenly mixed within blood collection tubes without damaging the blood cells, which is essential for hematology and coagulation studies.

Maintaining Liquid-Solid Suspensions

When working with suspensions, such as cultures or reagents with insoluble particles, a roller mixer keeps the solids evenly distributed throughout the liquid for extended periods. This prevents settling without breaking down the particles themselves.

Blending Viscous Substances

The constant, slow turning is effective for gradually mixing thick or viscous liquids that would resist more rapid mixing methods. The motion allows layers to fold into each other consistently over time.

Assisting with Thawing

Roller mixers can also be used to gently agitate samples while they thaw. The constant movement helps to distribute heat more evenly, speeding up the defrosting process without creating localized hot spots that could damage the sample.

Understanding the Trade-offs

While excellent for gentle applications, a roller mixer is not a universal solution. It is a specialized tool with clear limitations.

Not Designed for High-Energy Mixing

A roller mixer is unsuitable for tasks that require vigorous agitation, such as rapidly dissolving solid powders or creating emulsions. The energy input is deliberately low.

Slower Mixing Times

Compared to a vortexer, the mixing process is significantly slower. It is designed for continuous, unattended operation over minutes or hours, not for rapid, on-the-spot mixing.

Limited Vessel Compatibility

The design is specifically for cylindrical tubes. It cannot accommodate flasks, beakers, or microplates, which require an orbital shaker or another type of mixer.

Making the Right Choice for Your Goal

Selecting the correct mixer depends entirely on the requirements of your sample and protocol.

- If your primary focus is preserving fragile cells (e.g., blood): The roller mixer is the industry standard and the correct choice.

- If your primary focus is keeping solids in suspension over time: A roller mixer provides the ideal, low-impact, continuous agitation required.

- If your primary focus is speed or dissolving solids quickly: A vortex mixer or magnetic stirrer is a more appropriate tool.

- If your primary focus is mixing viscous liquids without aeration: The roller mixer is an excellent option for slow, consistent blending.

Ultimately, selecting a roller mixer is a deliberate choice for gentle, consistent, and low-impact sample handling.

Summary Table:

| Application | Primary Benefit | Ideal For |

|---|---|---|

| Mixing Blood Samples | Prevents cell damage (hemolysis) | Hematology, coagulation studies |

| Maintaining Suspensions | Keeps solids evenly distributed | Cell cultures, reagents with particles |

| Blending Viscous Liquids | Ensures consistent, slow mixing | Thick reagents, solutions |

| Assisting Sample Thawing | Promotes even heat distribution | Gently thawing frozen samples |

Need to preserve your sensitive samples during mixing? KINTEK's roller mixers provide the gentle, end-over-end agitation essential for working with blood, cell cultures, and viscous liquids without introducing damaging air bubbles. Our equipment ensures sample integrity and reliable results for your laboratory. Contact our experts today to find the perfect roller mixer for your application!

Visual Guide

Related Products

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Oscillating Orbital Shaker

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- How does a constant temperature rotary shaker contribute to evaluating iron nanoparticles? Optimize Dye Degradation

- Why is precision mixing required for concrete corrosion studies? Ensure Data Integrity through Homogenization

- Why is a rotary mechanical homogenizer used for extended periods for forsterite-spinel? Achieve Peak Ceramic Uniformity

- How does a high-efficiency homogenizing mixer contribute to the preparation of Tobermorite and Xonotlite precursors?

- What is the function of high-shear dispersion equipment in corona-resistant nanocomposites? Elevate Your Insulation