At its core, a screw press is a machine designed for the continuous separation of liquids from solids. It functions by using a slowly rotating helical screw (an auger) to convey and simultaneously compress material against a perforated screen, forcing the liquid out while retaining the solid fraction. This simple, robust mechanism makes it a cornerstone technology in numerous dewatering and thickening applications.

A screw press excels by applying gradual, consistent mechanical pressure to dewater high-moisture materials. Its key advantages are high energy efficiency, low operational speed, and automated, continuous processing, making it ideal for industries that need to reduce waste volume or reclaim valuable liquids.

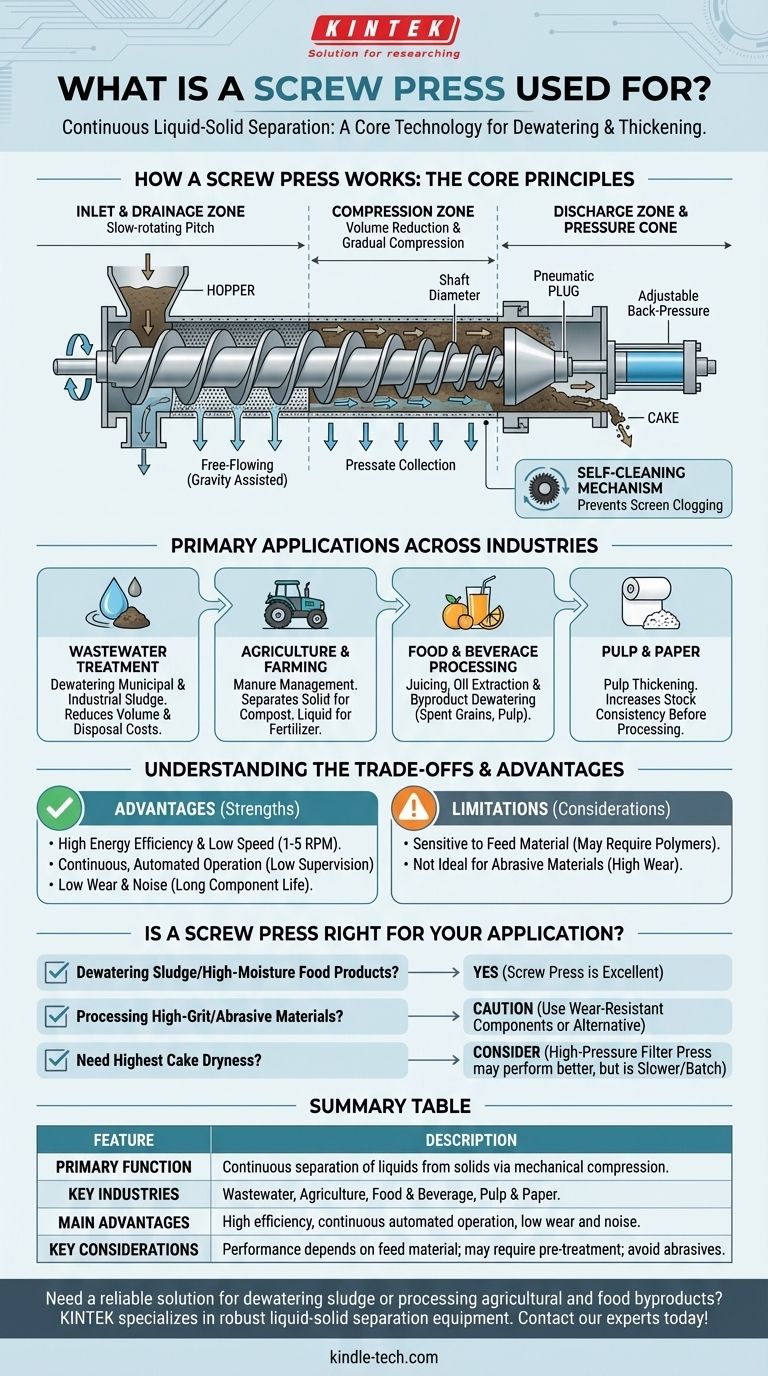

How a Screw Press Works: The Core Principles

Understanding a screw press requires looking at its three functional zones, which work together to progressively dewater the feed material.

The Inlet and Drainage Zone

Material, often in a slurry or sludge form, is fed into the inlet of the press. In this initial section, the screw's primary job is conveyance. Gravity assists in draining free-flowing liquid through the perforated screen before any significant pressure is applied.

The Compression Zone

This is the heart of the machine. The design of the screw changes, either through a decreasing flight pitch (the distance between the screw "threads") or an increasing shaft diameter. Both methods systematically reduce the available volume for the material as it moves forward. This gradual compression squeezes the liquid out of the solids.

The Discharge Zone and Pressure Cone

At the end of the screw, the dewatered solid, now called "cake," is pushed against a resistance point, typically a pneumatic or spring-loaded cone. This back-pressure is adjustable and ensures the material is sufficiently compressed before it is discharged. The solid cake exits the machine, while the separated liquid (pressate) is collected from beneath the screen.

The Self-Cleaning Mechanism

Modern screw presses, particularly those used for sludgy materials, incorporate moving rings or a rotating brush. As the screw turns, these elements move against the screen, preventing the fine solids from clogging the screen perforations and ensuring consistent dewatering performance.

Primary Applications Across Industries

The versatility of the screw press makes it indispensable in a wide range of sectors.

Wastewater Treatment

This is one of the most common applications. Screw presses are used to dewater municipal and industrial sludge, significantly reducing its volume. This lowers transportation and disposal costs and creates a drier "biosolid" cake that can sometimes be used as fertilizer or fuel.

Agriculture and Farming

Screw presses are highly effective for dewatering animal manure. Separating the liquid and solid components allows for easier management, reduces odor, and creates a solid fraction suitable for composting and a liquid fraction for controlled land application as fertilizer.

Food and Beverage Processing

In this industry, the goal can be either waste reduction or valuable liquid extraction. Presses are used to juice fruits and vegetables, extract oils from seeds, and dewater processing byproducts like spent grains from breweries or fruit pulp.

Pulp and Paper

The pulp and paper industry uses screw presses for thickening pulp stock. By removing water from the fiber slurry, the press increases the consistency of the pulp, which is a critical step before bleaching, refining, or paper machine processing.

Understanding the Trade-offs and Advantages

While powerful, a screw press is not a universal solution. Understanding its strengths and weaknesses is crucial for proper application.

Advantage: High Efficiency and Low Energy Use

The slow rotational speed (typically 1-5 RPM) means screw presses consume very little energy compared to high-speed alternatives like centrifuges. This translates directly to lower operational costs.

Advantage: Continuous and Automated Operation

Unlike batch processes, a screw press runs continuously with minimal operator supervision. This automation reduces labor requirements and provides a consistent output.

Advantage: Low Speed, Low Wear, and Low Noise

The slow-moving parts generate very little noise and vibration. This slow operation also results in less wear and tear, leading to longer component life and lower maintenance costs, provided the feed material is not highly abrasive.

Limitation: Sensitivity to Feed Material

The performance of a screw press can be heavily influenced by the characteristics of the incoming material. For example, wastewater sludge often requires pre-treatment with polymers to properly flocculate (clump together) before it can be effectively dewatered.

Limitation: Not Ideal for Abrasive Materials

Materials containing significant amounts of sand, grit, or other abrasive particles can cause premature and costly wear on the screw flights and the screen. In these cases, hardened components or alternative technologies may be necessary.

Is a Screw Press Right for Your Application?

Choosing the right dewatering technology depends entirely on your material and your operational goals.

- If your primary focus is dewatering municipal or industrial sludge: A screw press is a leading technology known for its efficiency, reliability, and low operating costs.

- If your primary focus is processing high-moisture agricultural or food products: A screw press is an excellent choice for separating liquids from fibrous or pulpy materials.

- If your primary focus is processing materials with high levels of grit or abrasives: You must proceed with caution and invest in wear-resistant components or evaluate alternative dewatering methods.

- If your primary focus is achieving the absolute highest cake dryness: A high-pressure filter press may outperform a screw press, but at the cost of being a slower, batch-based process.

Ultimately, the screw press is an engineering workhorse, providing a simple and efficient solution for countless liquid-solid separation challenges.

Summary Table:

| Feature | Description |

|---|---|

| Primary Function | Continuous separation of liquids from solids via mechanical compression. |

| Key Industries | Wastewater treatment, Agriculture, Food & Beverage, Pulp & Paper. |

| Main Advantages | High energy efficiency, continuous automated operation, low wear and noise. |

| Key Considerations | Performance depends on feed material; may require pre-treatment; not ideal for highly abrasive materials. |

Need a reliable solution for dewatering sludge or processing agricultural and food byproducts? KINTEK specializes in robust laboratory and processing equipment, including technologies for efficient liquid-solid separation. Our expertise can help you reduce waste volume, lower disposal costs, and improve your process efficiency. Contact our experts today to discuss how we can support your specific application needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.