In short, a sintering oven is a specialized furnace that transforms a mass of loose particles, like metal or ceramic powder, into a solid object. It accomplishes this using high heat and sometimes pressure, but crucially, it operates below the material's melting point, fusing the particles together at a molecular level rather than melting them into a liquid.

The fundamental advantage of a sintering oven is its ability to create solid parts without melting the base material. This unique process enables the manufacturing of components with highly controlled properties—from porous filters to parts made of extremely high-melting-point metals—that would be difficult or impossible to produce through traditional casting.

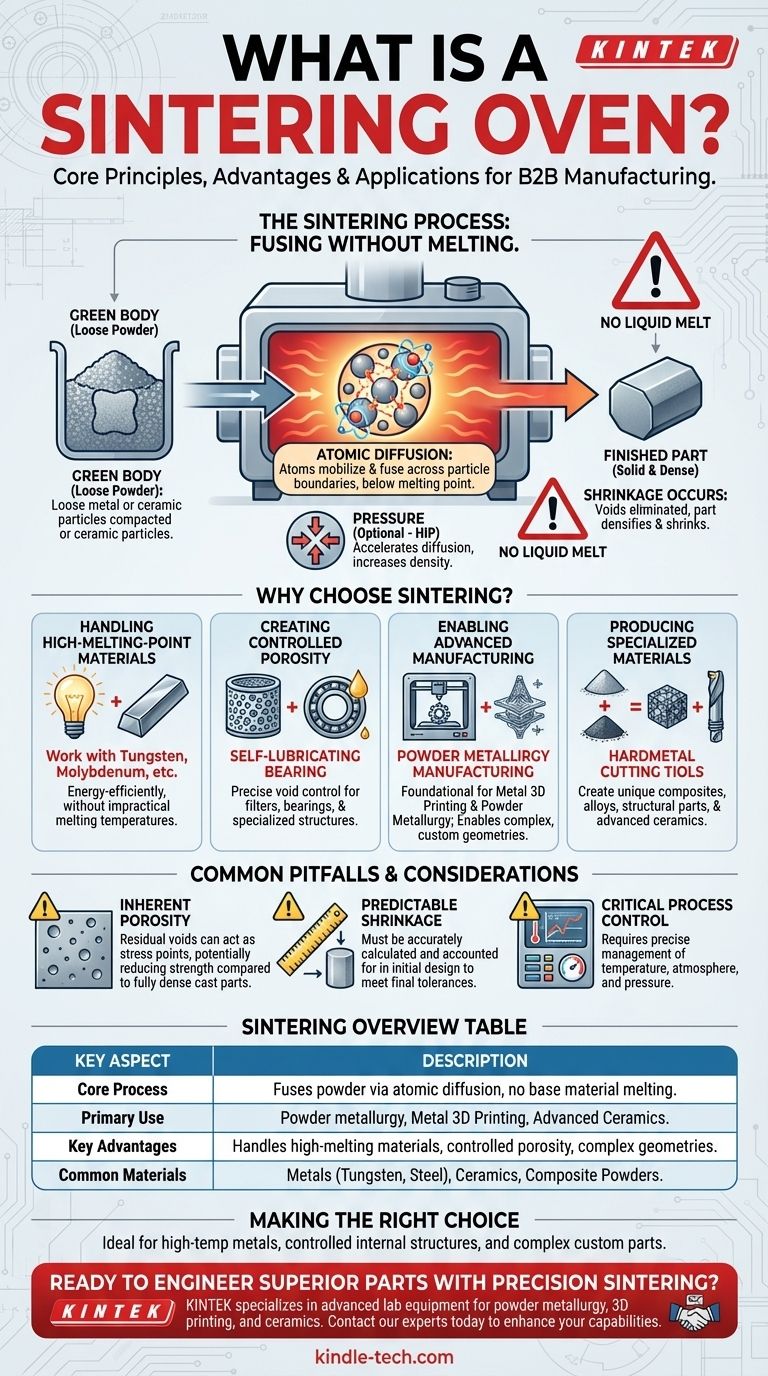

The Core Principle: Fusing Without Melting

To truly understand a sintering oven, you must first grasp the process it facilitates. It's less about brute force heating and more about precise material science.

How It Works: Atomic Diffusion

A sintering oven applies controlled heat that energizes the atoms on the surface of each individual particle in a powder.

This energy isn't enough to cause a full melt, but it makes the atoms highly mobile. They begin to diffuse across the boundaries between particles, forming strong metallic or chemical bonds that lock the particles together into a solid piece.

From "Green Body" to Finished Part

The process typically starts with a "green body"—the loose powder that has been compacted or formed into a preliminary shape. This green body is fragile.

Inside the oven, the sintering process eliminates the voids between particles, causing the object to shrink and densify into a strong, coherent final part.

The Role of Pressure

In many advanced applications, pressure is applied along with heat. This is known as hot isostatic pressing (HIP).

The external pressure physically squeezes the particles together, which accelerates the atomic diffusion process and results in a final part with even higher density and improved mechanical properties.

Why Choose Sintering Over Traditional Melting?

The decision to use a sintering oven is driven by the unique capabilities that melting and casting cannot offer. It provides solutions for specific engineering challenges.

Handling High-Melting-Point Materials

Materials like tungsten have melting points so high that melting and casting them is commercially impractical and incredibly energy-intensive.

Sintering allows for the creation of solid tungsten parts, such as lamp filaments, at temperatures that are significantly lower and more manageable than its melting point.

Creating Controlled Porosity

Because sintering fuses particles together instead of turning them into a uniform liquid, engineers can precisely control the amount of empty space (porosity) in the final product.

This is essential for manufacturing components like self-lubricating bearings, which are designed to hold oil in their porous structure, or specialized metal and plastic filters.

Enabling Advanced Manufacturing

Sintering is the foundational technology behind most metal 3D printing (additive manufacturing) and powder metallurgy.

Complex, custom metal parts are built layer by layer by fusing metal powder together with a laser or other energy source. This allows for intricate geometries that would be impossible to machine from a solid block or cast in a mold.

Producing Specialized Materials

Sintering allows for the combination of different powdered materials to create unique composites and alloys. It is used to produce everything from structural steel parts and electrical contacts to hardmetal cutting tools and advanced ceramics.

Common Pitfalls and Considerations

While powerful, the sintering process has inherent trade-offs that must be managed for a successful outcome.

Inherent Porosity Can Be a Weakness

While porosity can be a desirable feature, any unwanted residual voids can act as stress points, potentially reducing the overall strength and fatigue resistance of a part compared to a fully dense, cast equivalent.

Predictable Shrinkage is Required

The densification process causes the part to shrink from its initial "green body" size. This shrinkage must be accurately calculated and accounted for in the initial design to ensure the final part meets dimensional tolerances.

Process Control is Critical

Sintering is not a simple "heat and cool" operation. Achieving the desired final properties requires precise control over the oven's temperature ramp-up and cool-down rates, the atmospheric conditions inside the chamber, and the pressure applied.

Making the Right Choice for Your Application

Selecting the right manufacturing process depends entirely on your end goal. Sintering excels where other methods fall short.

- If your primary focus is manufacturing with high-temperature metals: Sintering is the most practical and energy-efficient method for working with materials like tungsten, molybdenum, or their alloys.

- If your primary focus is creating parts with controlled internal structures: Sintering is the ideal choice for producing porous filters, self-lubricating bearings, or other components where voids are a design feature.

- If your primary focus is complex, custom metal part fabrication: Sintering is the core technology behind metal 3D printing and powder metallurgy, enabling intricate geometries that are difficult to machine or cast.

Ultimately, a sintering oven provides a powerful method for engineering materials from the particle level up, offering a degree of control that traditional melting simply cannot match.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Process | Fuses powder particles via atomic diffusion, without melting the base material. |

| Primary Use | Powder metallurgy, metal 3D printing, and manufacturing of advanced ceramics. |

| Key Advantages | Handles high-melting-point materials, creates controlled porosity, enables complex geometries. |

| Common Materials | Metals (tungsten, steel), ceramics, and composite powders. |

Ready to engineer superior parts with precision sintering?

KINTEK specializes in advanced lab equipment and consumables, providing the sintering solutions your laboratory needs to master powder metallurgy, 3D printing, and advanced ceramics. Our expertise ensures precise process control for optimal material properties and part performance.

Contact our experts today to discuss how our sintering ovens can enhance your research and manufacturing capabilities.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag