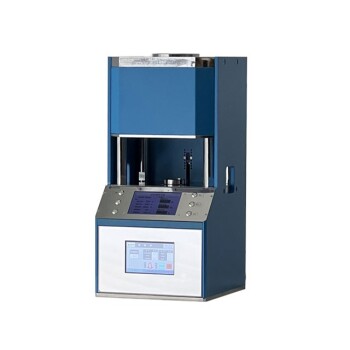

A type casting machine is a specialized device used in the printing industry to produce individual characters for typesetting.

This machine operates by casting metal type from matrices.

Matrices are small, mold-like pieces that define the shape of each character.

The process involves melting a metal alloy and then pouring it into the matrices to form the characters.

Once the metal cools and solidifies, the characters are ready for use in typesetting.

Type casting machines were pivotal in the evolution of printing technology, enabling the mass production of typefaces with high precision and consistency.

5 Key Points Explained

Definition and Function

A type casting machine is a device used in printing to create individual metal characters for typesetting.

It operates by casting molten metal into matrices, which are molds that define the shape of each character.

Process of Type Casting

Melting: The metal used for casting is typically an alloy that melts at a relatively low temperature. This metal is melted in a crucible or furnace.

Casting: Once melted, the metal is poured into the matrices. Each matrix corresponds to a specific character in the font.

Solidification: After pouring, the metal cools and solidifies, forming the individual characters.

Post-processing: The newly cast characters are then cleaned and prepared for use in typesetting.

Historical Significance

The invention of type casting machines, such as the Monotype machine invented by Tolbert Lanston in 1887, revolutionized the printing industry.

It allowed for the mass production of high-quality, consistent typefaces, which significantly improved the efficiency and quality of printing.

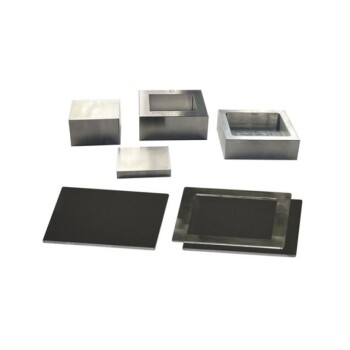

Components of a Type Casting Machine

Matrix Case: This holds all the matrices for a specific font, ensuring that each character can be cast as needed.

Melting Chamber: This is where the metal is melted before being cast. It is typically equipped with temperature control mechanisms to ensure the metal is at the correct temperature for casting.

Casting Mechanism: This part of the machine is responsible for pouring the molten metal into the matrices and controlling the flow to ensure accurate casting.

Advantages of Type Casting Machines

Precision: Type casting machines produce characters with high precision, ensuring consistent and accurate typesetting.

Efficiency: These machines allow for the rapid production of typefaces, which increases the speed of printing processes.

Customization: They enable the creation of custom fonts and characters, which can be tailored to specific printing needs.

Modern Applications

While digital typesetting has largely replaced mechanical type casting in modern printing, type casting machines played a crucial role in the history of printing and remain an important part of its technological heritage.

They are still used in some specialized applications where traditional metal type is preferred.

In summary, a type casting machine is a specialized device that revolutionized the printing industry by enabling the precise and efficient production of metal typefaces.

Its invention and development have had a lasting impact on printing technology, and it remains a significant part of the history and evolution of typesetting.

Continue exploring, consult our experts

Unlock the precision of printing past with a KINTEK SOLUTION type casting machine.

Experience the unmatched efficiency and customization of high-quality typefaces, tailored to your every need.

Don't let history fade; embrace the future of typesetting.

Contact us today to revolutionize your printing processes and elevate your design possibilities.

Learn how KINTEK SOLUTION's cutting-edge technology can transform your project's potential.