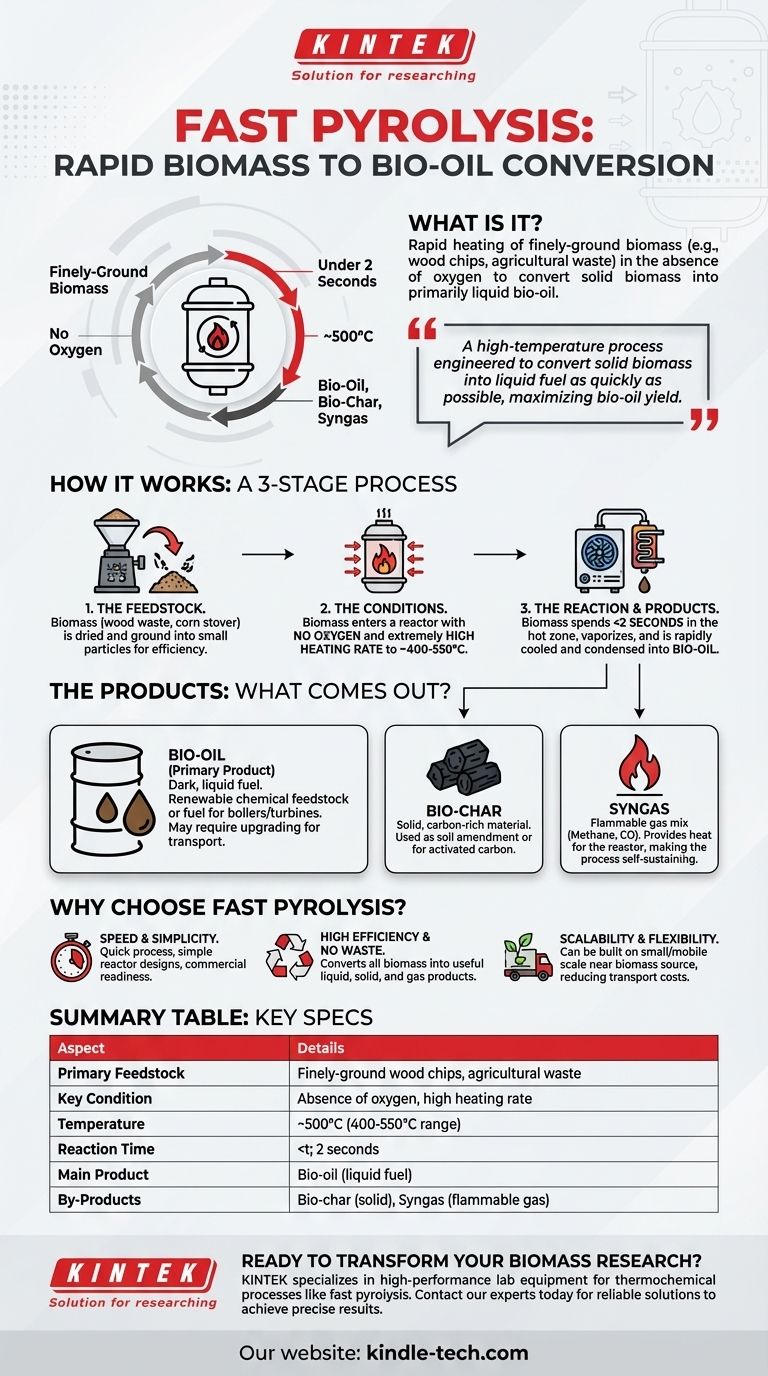

A primary example of fast pyrolysis is the rapid heating of finely-ground wood chips or agricultural waste in a reactor without oxygen. In under two seconds, at temperatures around 500°C, this solid biomass is converted primarily into a dark, liquid fuel known as bio-oil, along with smaller amounts of bio-char and flammable syngas.

Fast pyrolysis is a high-temperature thermochemical process engineered for a single purpose: to convert solid biomass into a liquid fuel as quickly as possible. The key is its extremely high heating rate and short reaction time, which maximizes the bio-oil yield by preventing the biomass from fully breaking down into char and gas.

How Fast Pyrolysis Works: A Step-by-Step Breakdown

To understand fast pyrolysis, it's best to look at it as a precisely controlled, three-stage process focused on transformation rather than burning.

The Feedstock: What Goes In?

The process begins with biomass. This is typically organic, non-fossil material like wood waste, corn stover, or other agricultural residues. For the reaction to be efficient, the biomass is usually dried and ground into small particles.

The Conditions: A Controlled Environment

The ground biomass is fed into a reactor where two conditions are critical. First, there is an absence of oxygen, which prevents normal combustion (burning). Second, there is an extremely high heating rate, bringing the biomass to a target temperature between 400-550°C almost instantly.

The Reaction: Less Than Two Seconds

The particles of biomass remain in this hot, oxygen-free zone for a very short period, typically less than two seconds. This brief, intense exposure is the "fast" in fast pyrolysis. It vaporizes the organic compounds before they have time to form more stable structures like charcoal.

The Products: What Comes Out?

The hot vapors are rapidly cooled and condensed into the main product: bio-oil. This liquid fuel is the primary goal of the process.

Two other products are also formed:

- Bio-char: A solid, carbon-rich material similar to charcoal that can be used as a soil amendment.

- Syngas: A mix of non-condensable, flammable gases like methane and carbon monoxide. This gas is often captured and burned to provide the heat for the reactor, making the process partially self-sustaining.

Why Choose Fast Pyrolysis? Key Advantages

Fast pyrolysis has gained attention because it offers several distinct operational benefits compared to other biomass conversion methods.

Speed and Simplicity

As the name implies, the process is extremely quick. The reactors required are also relatively simple in design and have reached a level of commercial production.

High Efficiency and No Waste

A key advantage is that all components of the biomass can be converted into a useful product. There is no waste stream, as the liquid, solid, and gas outputs all have applications.

Scalability and Flexibility

Fast pyrolysis facilities can be built on a relatively small, even mobile, scale. This allows them to be placed near the source of biomass, reducing transportation costs for bulky raw materials. The dense bio-oil can then be transported more efficiently to a central facility for further processing.

Understanding the Trade-offs and Applications

While powerful, it is crucial to understand the nature of the products and their real-world uses.

The Nature of Bio-Oil

The liquid produced is called bio-oil, but it is not a direct replacement for refined petroleum fuels like gasoline or diesel. It is a complex mixture that can be acidic and unstable.

This bio-oil often requires further processing, known as upgrading, before it can be used as a transportation fuel. Without upgrading, it is more suitable as a fuel for industrial boilers, engines, and turbines.

Practical Applications

The products from a single fast pyrolysis run can serve different markets. The bio-oil can be a source of renewable industrial fuel or chemical feedstocks. The bio-char is valued as a soil amendment or for producing activated carbon. The syngas provides energy to sustain the process.

Making the Right Choice for Your Goal

Selecting the right thermal process depends entirely on your desired end product.

- If your primary focus is producing a liquid biofuel from waste biomass: Fast pyrolysis is the most direct and efficient method, as it is specifically designed to maximize bio-oil yield.

- If your primary focus is creating stable carbon for soil amendment: Slower pyrolysis processes are a better choice, as they are optimized to produce a much higher yield of bio-char.

- If your primary focus is generating flammable gas for immediate power: While fast pyrolysis produces syngas, a process like gasification would be more effective as it is designed to maximize gas output.

Ultimately, fast pyrolysis stands out as a rapid and efficient technology for transforming bulky, low-value biomass into a dense, transportable liquid energy carrier.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Feedstock | Finely-ground wood chips, agricultural waste |

| Key Condition | Absence of oxygen, high heating rate |

| Temperature | ~500°C (400-550°C range) |

| Reaction Time | < 2 seconds |

| Main Product | Bio-oil (liquid fuel) |

| By-Products | Bio-char (solid), Syngas (flammable gas) |

Ready to transform your biomass research or production? KINTEK specializes in high-performance lab equipment and consumables for thermochemical processes like fast pyrolysis. Whether you're developing new biofuels or optimizing reactor conditions, our reliable solutions help you achieve precise temperature control and efficient results. Contact our experts today to discuss how we can support your laboratory's specific needs in biomass conversion and renewable energy.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- High Performance Laboratory Freeze Dryer

People Also Ask

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time