Batch pyrolysis is an operational method for thermally decomposing materials like wood or plastic in a sealed, low-oxygen environment, one finite load at a time. In this process, a set quantity of feedstock is loaded into a reactor, the entire heating and conversion cycle is completed, and the resulting products are unloaded. Only then can the next cycle begin.

The term "batch" does not describe the chemical reaction itself, but rather the operational logistics of how the process is run. Think of it as baking a cake in an oven—you load ingredients, run a cycle, and empty it—as opposed to a continuously moving conveyor belt that processes material without stopping.

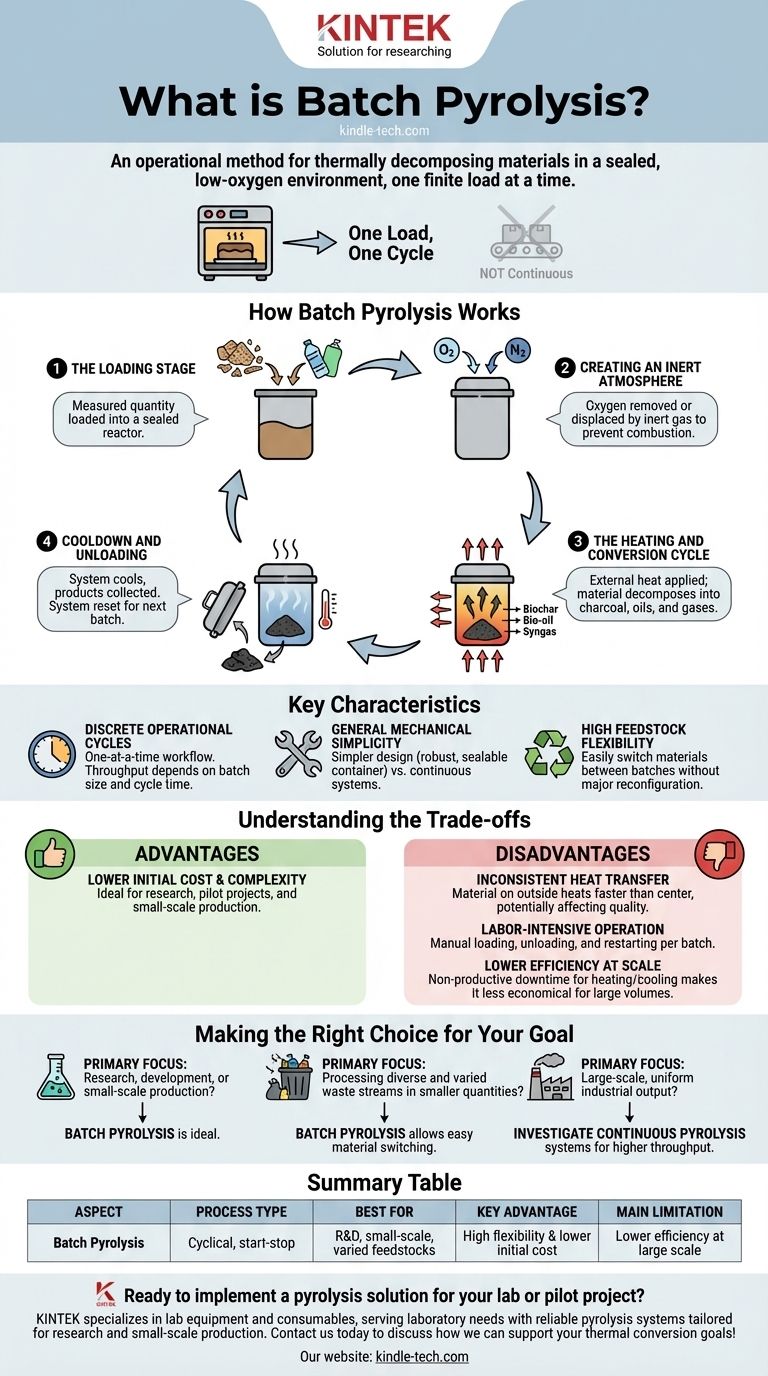

How Batch Pyrolysis Works

Batch pyrolysis follows a distinct, cyclical "start-stop" sequence. Each step must be completed before the next can begin for a given load of material.

The Loading Stage

The process begins by loading a measured quantity, or "batch," of feedstock into a sealed reactor vessel. This could be wood chips, plastic waste, or other organic material.

Creating an Inert Atmosphere

Once sealed, the oxygen inside the reactor is removed or displaced, often by purging it with an inert gas like nitrogen. This is critical because heating the material in the presence of oxygen would cause combustion (burning), not pyrolysis.

The Heating and Conversion Cycle

External heat is applied to the reactor, raising the temperature of the feedstock inside. As the material heats up without oxygen, it thermally decomposes into various products, which can include charcoal (biochar), liquid oils (bio-oil), and gases (syngas).

Cooldown and Unloading

After the reaction is complete, the system is cooled down. The reactor is then opened, and the solid products, like charcoal, are removed. The liquids and gases are collected separately. The entire system must be prepared before the next batch can be loaded.

Key Characteristics of Batch Systems

The cyclical nature of batch processing gives it a distinct set of operational characteristics that differentiate it from continuous methods.

Discrete Operational Cycles

The defining feature is its one-at-a-time workflow. The total throughput is determined by the size of the batch and the time it takes to complete one full cycle (loading, heating, cooling, unloading).

General Mechanical Simplicity

Compared to continuous systems that require complex feeding and discharge mechanisms to operate without stopping, batch reactors are often simpler in design. They are essentially a robust, sealable, and heatable container.

High Feedstock Flexibility

Batch systems are exceptionally flexible. Because each run is a discrete event, you can easily switch from processing one type of material (e.g., wood) in one batch to another (e.g., plastic) in the next without major reconfiguration.

Understanding the Trade-offs

The simplicity and flexibility of batch pyrolysis come with significant trade-offs, making it ideal for some applications and unsuitable for others.

Advantage: Lower Initial Cost and Complexity

The simpler design of batch reactors typically translates to lower capital investment. This makes them highly suitable for research, pilot projects, and small-scale specialty production.

Disadvantage: Inconsistent Heat Transfer

Heating a large, static pile of material evenly is a major challenge. The material on the outside of the batch heats up faster than the material in the center, which can lead to inconsistent product quality.

Disadvantage: Labor-Intensive Operation

The manual steps of loading, unloading, and restarting the cycle for each batch make the process more labor-intensive per unit of product compared to automated, continuous systems.

Disadvantage: Lower Efficiency at Scale

The time spent heating the reactor up and cooling it down between batches is non-productive "downtime." For large-scale industrial production, this inefficiency makes batch processing less economical than continuous alternatives.

Making the Right Choice for Your Goal

Selecting batch pyrolysis depends entirely on your specific objectives, scale, and the materials you intend to process.

- If your primary focus is research, development, or small-scale production: The flexibility and low initial cost of batch pyrolysis make it the ideal choice.

- If your primary focus is processing diverse and varied waste streams in smaller quantities: Batch processing allows you to easily switch between different types of materials without reconfiguring the system.

- If your primary focus is large-scale, uniform industrial output: You should investigate continuous pyrolysis systems, as they offer higher throughput and greater efficiency for high-volume operations.

Ultimately, understanding the operational rhythm of batch pyrolysis is the key to deploying it effectively for specific, targeted applications.

Summary Table:

| Aspect | Batch Pyrolysis |

|---|---|

| Process Type | Cyclical, start-stop |

| Best For | R&D, small-scale, varied feedstocks |

| Key Advantage | High flexibility & lower initial cost |

| Main Limitation | Lower efficiency at large scale |

Ready to implement a pyrolysis solution for your lab or pilot project? KINTEK specializes in lab equipment and consumables, serving laboratory needs with reliable pyrolysis systems tailored for research and small-scale production. Our expertise ensures you get the right setup for processing diverse materials like wood or plastic waste efficiently. Contact us today to discuss how we can support your thermal conversion goals!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What role does a constant temperature forced-air drying oven play in loading metal oxides? Ensure Catalyst Stability

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What are the different types of melting process? From Smelting to Suspension for Ultimate Purity

- Can biomass be used for transportation? A Guide to Biofuels, Processes, and Trade-offs

- How does a laboratory forced-air drying oven process ternary nanocomposite products? Ensure Nanostructural Integrity

- How does a mechanical propulsion system ensure HEA-NP quality? Master Fast Moving Bed Pyrolysis with Precision Control

- How long does it take for a house to cool down after heat treatment? A Guide to Safe & Speedy Recovery

- What is calcination? A Guide to High-Temperature Purification and Transformation