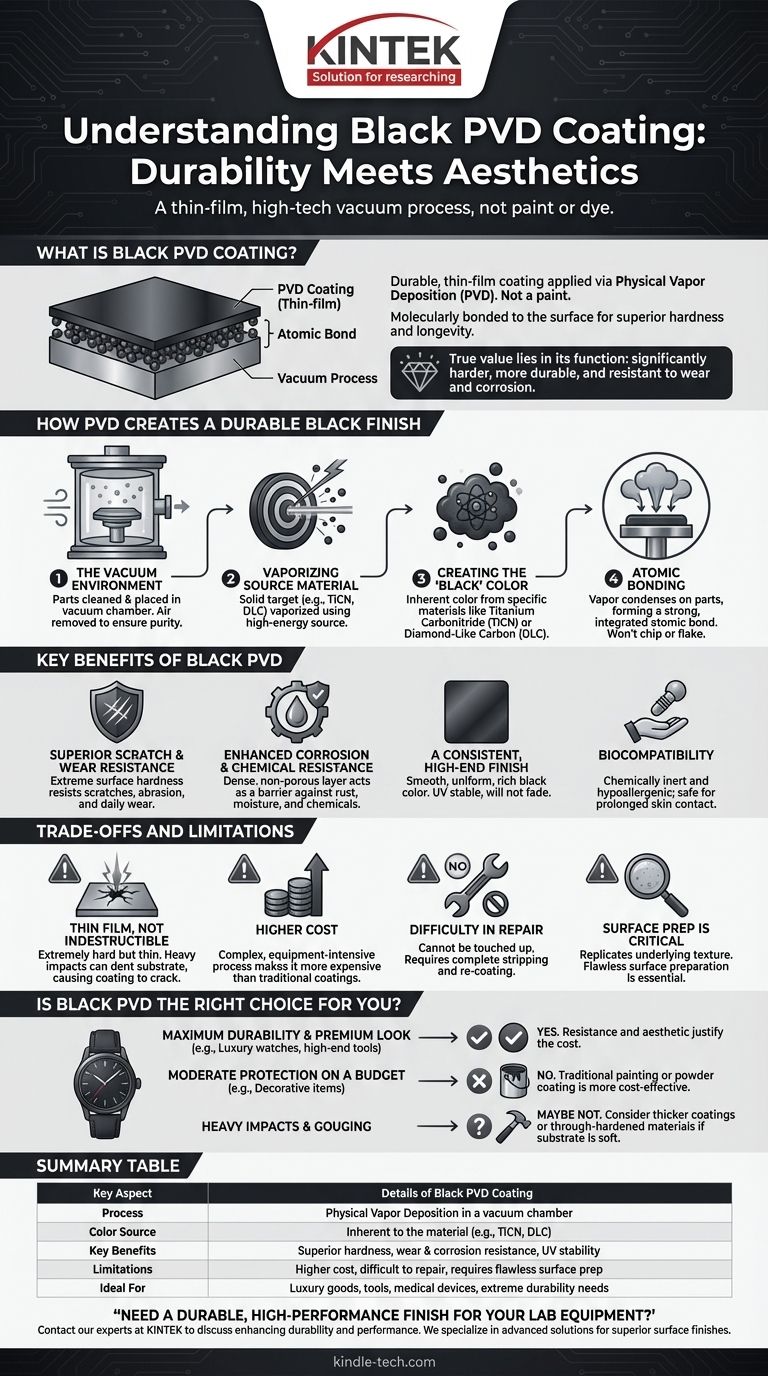

At its core, black PVD is not a paint or a dye, but a durable, thin-film coating applied in a high-tech vacuum process. Physical Vapor Deposition (PVD) involves vaporizing a solid material, often a metal or ceramic, and depositing it atom-by-atom onto a surface. The "black" color is determined by the specific material used and the process parameters, resulting in a finish that is molecularly bonded to the underlying part.

While often chosen for its sleek, black aesthetic, the true value of PVD coating lies in its function. It creates a surface that is significantly harder, more durable, and more resistant to wear and corrosion than traditional finishing methods.

How PVD Creates a Durable Black Finish

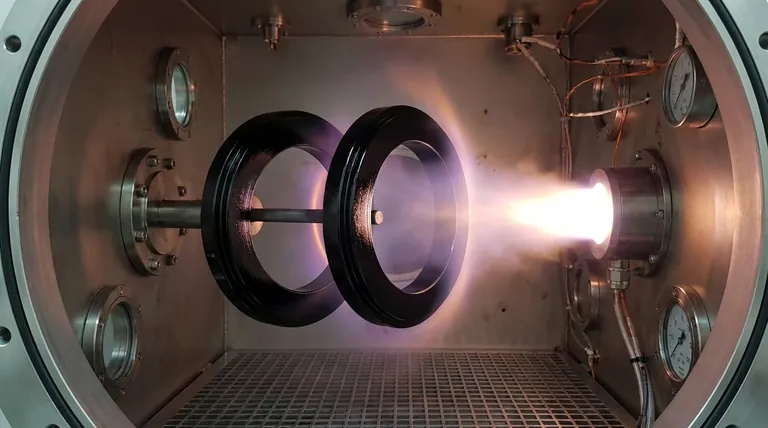

Understanding the PVD process reveals why it's fundamentally different from painting or plating. The entire operation takes place within a specialized vacuum chamber to ensure purity and adhesion.

The Vacuum Environment

First, the parts to be coated are meticulously cleaned and placed in a vacuum chamber. All the air is pumped out, creating an environment free from contaminants that could interfere with the coating's bond.

Vaporizing the Source Material

A solid "target" material, chosen for its properties, is then vaporized. This is typically done using a high-energy source, like an electric arc or a magnetic field (sputtering), which bombards the target and releases atoms or small clusters of atoms.

Creating the "Black" Color

The color of the PVD coating is inherent to the material being deposited. For a black finish, common materials include Titanium Carbonitride (TiCN) or specialized compositions like Chromium Nitride (CrN) and Diamond-Like Carbon (DLC). These materials are naturally dark gray or black when applied as a thin film.

Atomic Bonding

The vaporized material travels across the vacuum chamber and condenses on the parts. Because of the energy involved, the coating doesn't just sit on top; it forms a strong, atomic bond with the surface of the part, creating a new, integrated surface layer. This is why PVD coatings don't chip or flake like paint.

Key Benefits of Black PVD

Users choose PVD when performance and longevity are critical. The aesthetic is often a welcome byproduct of its superior functional properties.

Superior Scratch and Wear Resistance

The materials used for PVD are ceramics, which are extremely hard. A black PVD coating dramatically increases the surface hardness of a product, making it highly resistant to scratches, abrasion, and daily wear.

Enhanced Corrosion and Chemical Resistance

The deposited layer is dense and non-porous, acting as a robust barrier. This protects the underlying material from moisture, salts, and common chemicals, preventing rust and corrosion.

A Consistent, High-End Finish

The PVD process yields a smooth, uniform, and rich black finish that is difficult to achieve with other methods. The color is exceptionally stable and will not fade from UV exposure.

Biocompatibility

Many PVD coatings, especially those used on watches and medical implants, are chemically inert and hypoallergenic. They do not react with human skin, making them a safe choice for items with prolonged contact.

Understanding the Trade-offs and Limitations

While powerful, PVD is not a perfect or universal solution. Objectivity requires acknowledging its limitations.

It's a Thin Film, Not Indestructible

PVD coatings are incredibly hard, but they are also very thin (typically a few microns). A sharp, heavy impact can dent the softer substrate material underneath the coating, causing the PVD layer to crack or chip at the point of impact.

Higher Cost Than Traditional Coatings

PVD is a complex, equipment-intensive process requiring a vacuum, high-energy sources, and precise controls. This makes it significantly more expensive than conventional options like powder coating or painting.

Difficulty in Repair

If a PVD finish is severely scratched or damaged, it cannot be "touched up." The only way to properly repair it is to chemically strip the entire part and re-coat it, which is often impractical or costly.

Surface Preparation is Critical

The PVD process perfectly replicates the texture of the underlying surface. Any small scratches, dings, or imperfections in the base material will be visible through the coating. A flawless PVD finish requires a flawlessly prepared part.

Is Black PVD the Right Choice for You?

Choosing a finish depends on balancing your goals for durability, appearance, and cost.

- If your primary focus is maximum durability and a premium look (e.g., luxury watches, high-end tools, firearms): Black PVD is the superior choice, as its resistance to wear and corrosion justifies the higher cost.

- If your primary focus is moderate protection on a budget (e.g., decorative items, low-contact parts): Traditional painting or powder coating are far more cost-effective solutions for achieving a black color without the need for extreme performance.

- If you need to coat a product subject to heavy impacts and gouging: The hardness of PVD may not prevent damage if the underlying material is soft; a thicker, more malleable coating or a through-hardened material might be more suitable.

Understanding that black PVD is a bonded material, not a simple paint, empowers you to choose the right finish based on true performance and longevity.

Summary Table:

| Key Aspect | Details of Black PVD Coating |

|---|---|

| Process | Physical Vapor Deposition in a vacuum chamber |

| Color Source | Inherent to the material (e.g., TiCN, DLC) |

| Key Benefits | Superior hardness, wear & corrosion resistance, UV stability |

| Limitations | Higher cost, difficult to repair, requires flawless surface prep |

| Ideal For | Luxury goods, tools, medical devices, and applications needing extreme durability |

Need a Durable, High-Performance Finish for Your Lab Equipment or Components?

Black PVD coating offers unmatched scratch resistance, corrosion protection, and a premium aesthetic that lasts. At KINTEK, we specialize in providing advanced lab equipment and consumables, including solutions for achieving superior surface finishes. Our expertise can help you determine if PVD is the right choice for your specific laboratory needs, ensuring your instruments and components perform reliably.

Contact our experts today to discuss how we can enhance the durability and performance of your lab equipment.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance