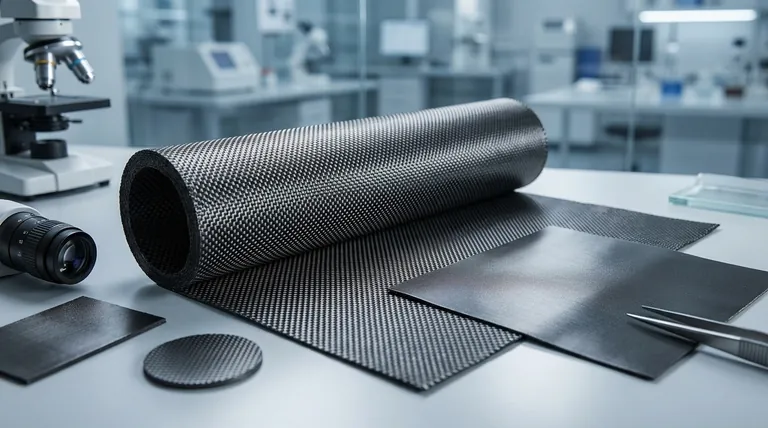

At its core, carbon cloth is a textile made by weaving together thousands of individual carbon fibers. This process transforms the exceptional properties of single carbon strands—which are incredibly strong but rigid—into a flexible, adaptable fabric that can be shaped, layered, and integrated into advanced materials and components.

The true significance of carbon cloth lies not just in its composition but in its structure. By weaving high-strength carbon fibers into a fabric, we create a material that is simultaneously strong, lightweight, conductive, and flexible, opening up applications impossible for raw fibers alone.

From Fiber to Fabric: The Composition

Understanding carbon cloth begins with its fundamental building block: the carbon fiber. These fibers are the source of the material's remarkable characteristics.

The Core Building Block: Carbon Fiber

Carbon fibers are microscopic crystalline filaments of carbon atoms. These fibers, often thinner than a human hair, possess an extraordinary strength-to-weight ratio, making them one of the strongest and lightest materials available.

The Weaving Process

Much like cotton or wool, these individual carbon fibers are woven together on industrial looms. This weaving process interlaces the fibers, creating a stable, sheet-like material—the carbon cloth. The specific weave pattern can be adjusted to change the cloth's handling characteristics and final properties.

Why This Structure Matters

Weaving is the critical step that makes carbon fiber so versatile. It translates the linear strength of the fibers into a two-dimensional fabric that is drapable and conformable, all while maintaining its inherent strength, chemical resistance, and conductivity.

The Defining Properties of Carbon Cloth

The woven structure of carbon cloth gives rise to a unique combination of beneficial properties that make it a cornerstone of high-performance engineering.

High Strength and Corrosion Resistance

Carbon cloth is exceptionally strong for its weight and is highly resistant to corrosion and chemical attack. This makes it ideal for use in harsh environments where metals or plastics would degrade.

Electrical and Thermal Conductivity

Unlike many fabrics, carbon cloth conducts both electricity and heat very well. This property is crucial for applications ranging from electromagnetic shielding to electrodes in batteries and fuel cells.

Flexibility and Large Surface Area

The woven nature provides excellent flexibility, allowing the cloth to be molded into complex shapes for composite manufacturing. This structure also creates a vast specific surface area, which is highly valuable for chemical reactions and filtration.

Understanding the Trade-offs

While carbon cloth is a superior material for many applications, it is essential to understand its limitations to use it effectively.

Brittleness and Impact Resistance

Although incredibly strong under tension, carbon fiber composites can be brittle. They may fracture or shatter under sharp, direct impacts, whereas a metal equivalent might only dent.

Electrical Conductivity as a Risk

Its excellent electrical conductivity can be a significant drawback in applications requiring electrical insulation. Accidental contact with live circuits can cause shorts and create a safety hazard if not properly managed in the design.

Cost and Manufacturing Complexity

Carbon fiber and the processes used to create carbon cloth are significantly more expensive than traditional materials like fiberglass or steel. Manufacturing requires specialized knowledge and equipment, adding to the overall cost.

Making the Right Choice for Your Application

Selecting carbon cloth depends entirely on whether its unique properties align with your primary engineering goal.

- If your primary focus is lightweight structural strength: Carbon cloth is an unparalleled choice for creating composite parts that need to be both rigid and light, such as in aerospace or high-performance vehicles.

- If your primary focus is electrochemical performance: Its high conductivity and massive surface area make it a top-tier material for electrodes in fuel cells, flow batteries, and supercapacitors.

- If your primary focus is high-temperature shielding or heating: Its thermal stability and conductivity allow it to function effectively as a furnace lining, heating element, or heat shield.

Ultimately, carbon cloth's value comes from its ability to solve engineering challenges that conventional materials simply cannot.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| High Strength-to-Weight Ratio | Lightweight structural integrity | Aerospace, Automotive Composites |

| Electrical & Thermal Conductivity | Efficient energy transfer | Battery & Fuel Cell Electrodes |

| Chemical Resistance & Flexibility | Durability in harsh environments | Filtration, High-Temperature Shielding |

| Large Surface Area | Enhanced chemical reactions | Supercapacitors, Catalytic Substrates |

Unlock the Potential of Carbon Cloth with KINTEK

Carbon cloth is a cornerstone of modern high-performance engineering, but its success depends on selecting the right material for your specific application. Whether you are developing next-generation energy storage, lightweight composites, or high-temperature systems, the unique properties of carbon cloth can provide a critical advantage.

KINTEK specializes in supplying high-quality lab equipment and consumables, including advanced materials like carbon cloth, to support your research and production needs. Our experts understand the nuances of material science and can help you identify the ideal carbon cloth weave or composite solution to meet your technical requirements and performance goals.

Let's build something exceptional together.

Contact our materials specialists today to discuss how carbon cloth can enhance your project and to explore our full range of laboratory solutions.

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Zinc Selenide ZnSe Optical Window Glass Substrate Wafer and Lens

People Also Ask

- What is the purpose of using an in-situ pressure monitoring device? Reveal Stress & Breathing Effects in SSB

- How is nickel foam utilized in the assembly of solid-state coin cells? Enhancing Interface Stability and Conductivity

- How does high-temperature heating contribute to the performance of Pt/FTO cathodes? Unlock Maximum DSSC Efficiency

- What is the structure of carbon felt? A Deep Dive into its 3D Porous Network

- What is the use of thin film semiconductor? Powering Modern Electronics from Microchips to Solar Cells

- What is the role of an electrochemical workstation with EIS in SOFC performance? Unlock Precision Diagnostics

- What is the necessity of using a silica-doped polyethylene membrane separator? Optimize Mo Dissolution Efficiency

- What type of battery test fixture is required for EIS composite cathode studies? Optimize Your Microstructure Analysis