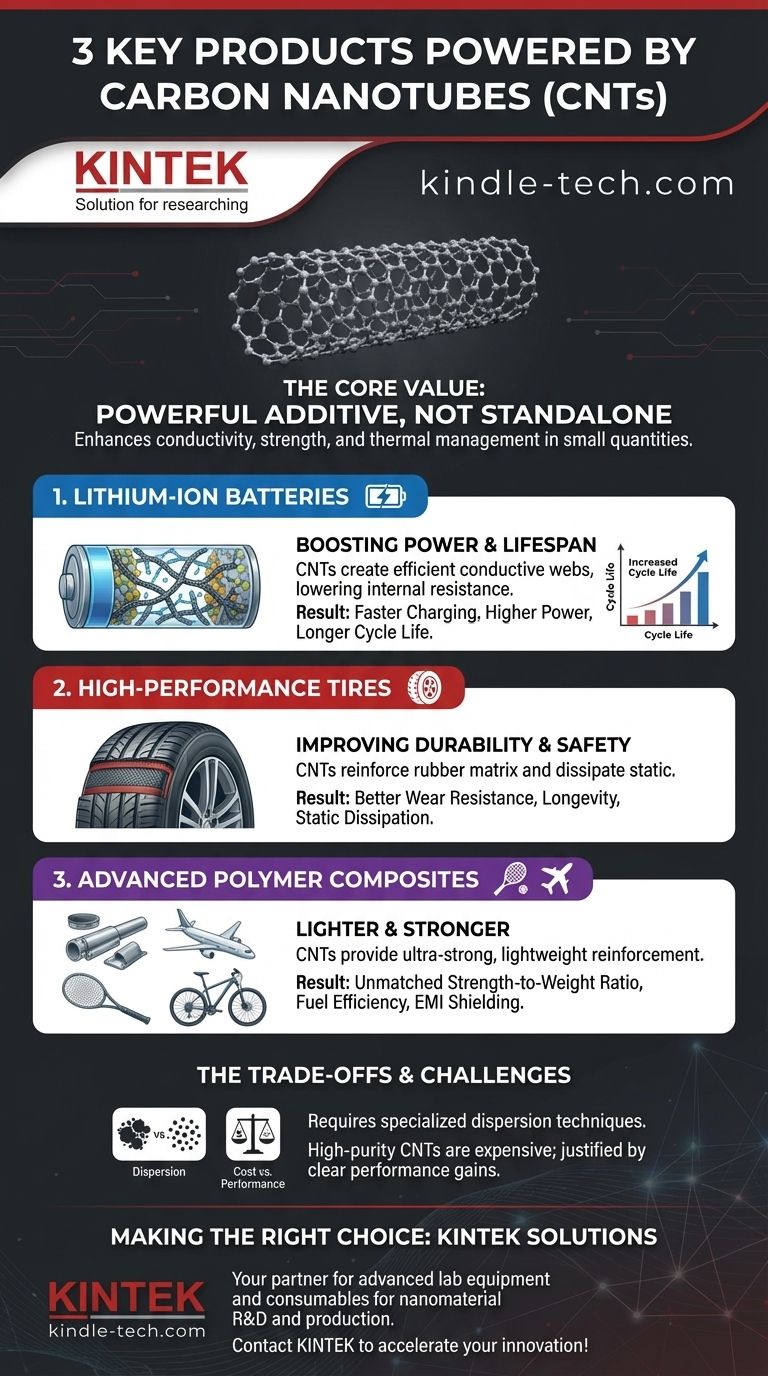

While often discussed in futuristic terms, carbon nanotubes (CNTs) are already integrated into several high-performance products available today. Three of the most significant applications are as conductive additives in lithium-ion batteries, as reinforcing agents in high-performance tires, and as a strengthening component in advanced polymer composites used in aerospace and sporting goods.

The core value of carbon nanotubes is not as a standalone material, but as a powerful additive. They are used in small quantities to grant existing materials extraordinary properties like enhanced electrical conductivity, superior strength, and improved thermal management.

The Role of CNTs: Enhancing Material Performance

Carbon nanotubes are molecular-scale tubes of graphitic carbon with a unique combination of properties. Engineers leverage these properties to solve specific performance bottlenecks in existing materials.

Electrical Conductivity: The Primary Driver

The most mature application for CNTs is driven by their exceptional ability to conduct electricity. They form a highly efficient, three-dimensional conductive network within other materials.

This is fundamentally different from traditional carbon black additives, which require much higher loading to achieve similar conductivity, often at the expense of other material properties.

Mechanical Strength: Lighter and Stronger

On a pound-for-pound basis, carbon nanotubes are one of the strongest and stiffest materials ever discovered.

When properly dispersed within a host material like a polymer or rubber, they act like microscopic rebar, drastically increasing the composite's strength and durability without adding significant weight.

Thermal Management: Dissipating Heat

In addition to conducting electricity, CNTs are excellent thermal conductors. This allows them to be used to draw heat away from critical components.

This property is becoming increasingly important in miniaturized electronics and high-power systems where heat dissipation is a primary limiting factor.

A Closer Look at Key Applications

While the potential applications are vast, the use of CNTs is most advanced in markets where performance gains justify the added cost and engineering complexity.

In Lithium-Ion Batteries: Boosting Power and Lifespan

This is the largest and most commercially successful application for CNTs. They are added to both the cathode and anode of lithium-ion batteries.

By creating a conductive web around the active material particles, CNTs lower the internal resistance of the battery. This allows for faster charging, higher power output, and a longer overall cycle life because the electrical and mechanical integrity is maintained during repeated expansion and contraction.

In High-Performance Tires: Improving Durability and Safety

Several tire manufacturers incorporate CNTs into their high-performance and commercial vehicle tire treads. The nanotubes reinforce the rubber matrix, improving wear resistance and longevity.

Furthermore, their conductivity helps dissipate static electricity buildup, which is a critical safety feature for industrial vehicles. This dual benefit of strength and conductivity makes them highly effective in this application.

In Advanced Composites: From Aircraft to Sporting Goods

CNTs are added to polymers to create ultra-strong, lightweight composites. These materials are found in high-end sporting goods like bicycle frames, tennis rackets, and hockey sticks, where players value stiffness and low weight.

In the aerospace industry, CNT-reinforced composites are used for aircraft components. Their strength-to-weight ratio helps reduce fuel consumption, and their conductivity can be used for lightning strike protection and electromagnetic interference (EMI) shielding.

Understanding the Trade-offs and Challenges

Despite their remarkable properties, integrating CNTs into products is not a simple process and involves significant engineering challenges.

The Challenge of Dispersion

By default, carbon nanotubes tend to clump together due to strong intermolecular forces, forming bundles or agglomerates. If not properly separated and dispersed, they are ineffective.

A significant portion of the cost and complexity in using CNTs lies in the proprietary techniques required to achieve a uniform dispersion within the host material (e.g., battery slurry, polymer, or rubber).

Cost vs. Performance Benefit

High-purity, high-quality carbon nanotubes are still a relatively expensive additive. Their use is typically only justified in applications where the performance improvement provides a clear competitive advantage that customers are willing to pay for.

As production methods scale and costs decrease, their adoption in more mainstream products is expected to accelerate.

Making the Right Choice for Your Goal

The decision to use carbon nanotubes is driven entirely by the specific performance target you need to achieve.

- If your primary focus is energy storage: CNTs offer a proven path to creating batteries with lower internal resistance, enabling faster charging and a longer service life.

- If your primary focus is structural materials: CNT-reinforced composites provide an unmatched strength-to-weight ratio for demanding aerospace, automotive, and high-end consumer products.

- If your primary focus is next-generation electronics: CNTs are a key enabling material for developing transparent conductive films for flexible displays and highly sensitive electronic sensors.

Ultimately, carbon nanotubes act as a key that unlocks the next level of performance in a wide range of advanced materials.

Summary Table:

| Product Application | Key Property Enhanced | Primary Benefit |

|---|---|---|

| Lithium-Ion Batteries | Electrical Conductivity | Faster charging, longer lifespan, higher power output |

| High-Performance Tires | Mechanical Strength & Conductivity | Improved wear resistance, longevity, and static dissipation |

| Advanced Polymer Composites | Strength-to-Weight Ratio | Lightweight, durable materials for aerospace and sporting goods |

Ready to Integrate High-Performance Materials into Your Products?

Carbon nanotubes can unlock the next level of performance for your applications, whether you're developing longer-lasting batteries, more durable tires, or lighter, stronger composites. At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary for R&D and production involving nanomaterials like CNTs.

Our expertise supports your journey from material dispersion challenges to final product integration, ensuring you achieve the superior electrical, mechanical, and thermal properties your projects demand.

Contact our experts today to discuss how KINTEK's solutions can accelerate your innovation in advanced materials!

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Aluminum Foil Current Collector for Lithium Battery

- High Purity Zinc Foil for Battery Lab Applications

- Battery Lab Equipment 304 Stainless Steel Strip Foil 20um Thick for Battery Test

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What are the different types of nanocarbons? A Guide to Fullerenes, Nanotubes, and Graphene

- What are the optical properties of CVD diamond? Unlock Unmatched Performance for Demanding Applications

- What happens during deposition chemistry? Building Thin Films from Gaseous Precursors

- What are the electrical applications of carbon nanotubes? Enhance Battery Performance & Electronics

- What are the categories of carbon nanotubes? Understand SWCNT vs. MWCNT for Your Application

- How does diamond like coating work? Unlock Superior Hardness and Low Friction

- What are the growth processes of thin films? Master the 3 Modes for Precise Material Engineering

- What are the factors affecting optical properties? Master the Atomic and Microstructural Influences