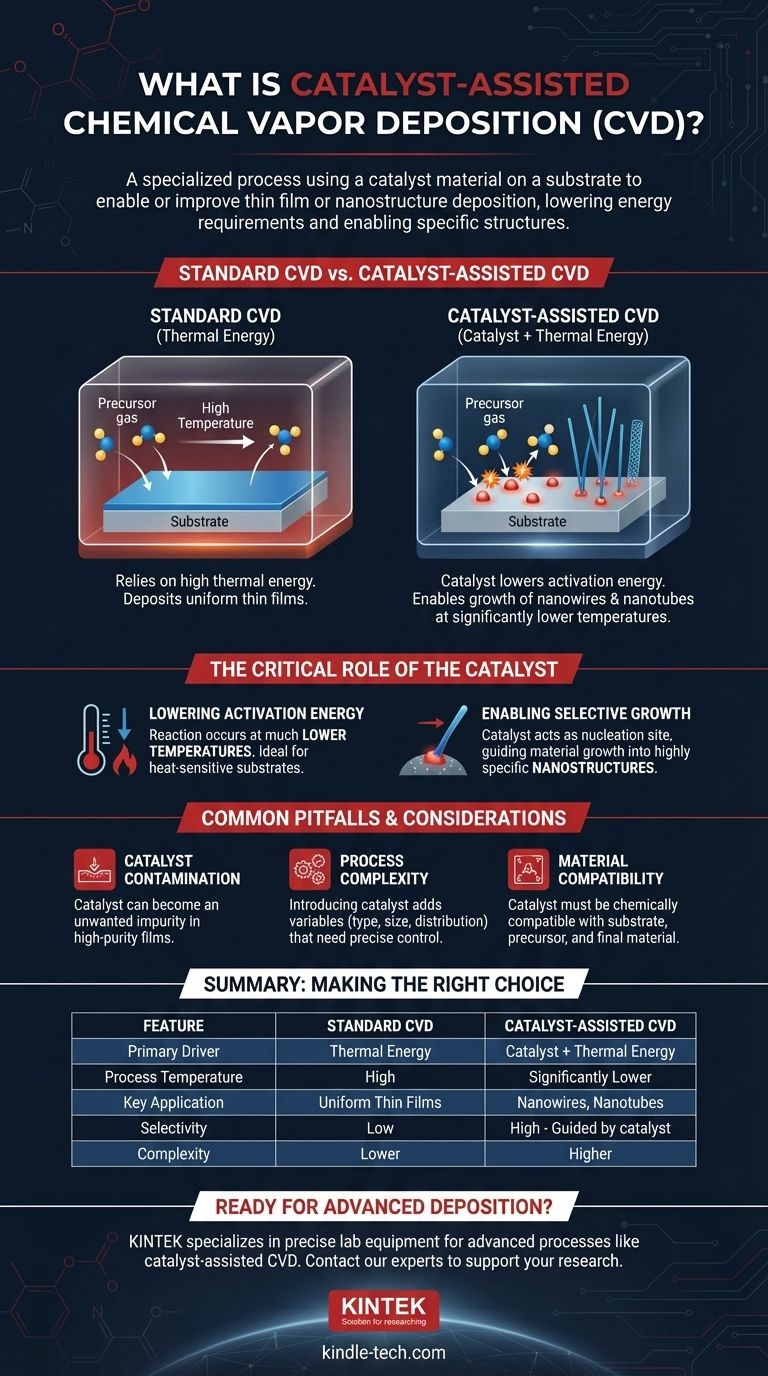

In short, catalyst-assisted Chemical Vapor Deposition (CVD) is a specialized process where a catalyst material is used on a substrate to enable or improve the deposition of a thin film or nanostructure. The catalyst lowers the energy required for the chemical reaction, often allowing the process to occur at lower temperatures or to create highly specific structures, like nanowires, that are not possible with standard CVD.

The core function of the catalyst is to act as a nucleation site and a reaction accelerator. It provides a specific location for precursor gases to break down and assemble into the desired solid material, guiding growth with a level of control that standard thermal energy alone cannot achieve.

A Primer on Standard Chemical Vapor Deposition (CVD)

What is CVD?

Chemical Vapor Deposition is a process used to create high-quality, high-performance solid materials, typically thin films. It involves placing a target object, or substrate, inside a reaction chamber.

Gaseous molecules, known as precursors, are then introduced into the chamber.

How Does it Work?

An energy source, usually high temperature, causes a chemical reaction or decomposition of the precursor gases on or near the substrate's surface.

This reaction results in the deposition of a stable solid film onto the substrate, while the gaseous byproducts are removed. This method is distinct from Physical Vapor Deposition (PVD), which uses physical means like melting or sputtering to create a vapor, rather than a chemical reaction.

What is it Used For?

CVD is essential in many industries. It's used to deposit thin films on semiconductors in electronics, create wear-resistant coatings for cutting tools, and manufacture photovoltaic materials for thin-film solar cells.

The Critical Role of the Catalyst

Standard CVD relies solely on thermal energy to drive the reaction. Catalyst-assisted CVD introduces a third component—the catalyst—which fundamentally changes the process.

Lowering the Activation Energy

The primary role of a catalyst in any chemical reaction is to lower the activation energy—the minimum energy required to initiate the reaction.

In CVD, this means the precursor gases can react and form the desired solid material at a much lower temperature than would otherwise be necessary. This is critical when working with substrates that cannot withstand high heat.

Enabling Selective and Anisotropic Growth

Perhaps the most powerful application of catalyst-assisted CVD is in growing one-dimensional nanostructures like nanowires and carbon nanotubes.

The catalyst, often a tiny metal nanoparticle, acts as a specific seed or nucleation site. The precursor gas decomposes exclusively on this catalyst particle, which then guides the material's growth in a single direction, forming a wire or tube.

Common Pitfalls and Considerations

Catalyst Contamination

A significant challenge is preventing the catalyst material from becoming an unwanted impurity in the final deposited film. For high-purity applications, this can be a critical drawback.

Process Complexity

Introducing a catalyst adds variables that must be precisely controlled. The type of catalyst, its particle size, and its distribution on the substrate all have a dramatic impact on the final result, adding complexity to the process design.

Material Compatibility

The choice of catalyst is not universal. It must be chemically compatible with the substrate, the precursor gases, and the desired final material to function correctly and avoid unwanted side reactions.

Making the Right Choice for Your Goal

When deciding on a deposition method, the specific outcome you need to achieve is the most important factor.

- If your primary focus is growing specific nanostructures like carbon nanotubes or nanowires: Catalyst-assisted CVD is not just an option; it is often the essential and most effective method.

- If your primary focus is depositing a film on a heat-sensitive substrate: Catalyst-assisted CVD can be the ideal solution, as it allows for significantly lower processing temperatures.

- If your primary focus is depositing a uniform, high-purity thin film with no complex geometry: Standard thermal or plasma-enhanced CVD may be a simpler, more direct approach that avoids potential catalyst contamination.

Ultimately, choosing to use a catalyst transforms CVD from a surface coating technique into a precision fabrication tool.

Summary Table:

| Feature | Standard CVD | Catalyst-Assisted CVD |

|---|---|---|

| Primary Driver | Thermal Energy | Catalyst + Thermal Energy |

| Process Temperature | High | Significantly Lower |

| Key Application | Uniform Thin Films | Nanowires, Nanotubes, Complex Structures |

| Selectivity | Low | High (Growth guided by catalyst sites) |

| Complexity | Lower | Higher (due to catalyst management) |

Ready to fabricate advanced nanostructures or deposit thin films on sensitive substrates?

KINTEK specializes in providing the precise lab equipment and consumables needed for advanced deposition processes like catalyst-assisted CVD. Whether you are developing next-generation electronics, cutting-edge sensors, or novel materials, our expertise and reliable products ensure your research and production goals are met with precision and efficiency.

Contact our experts today to discuss how we can support your specific laboratory needs and help you achieve superior results.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Multi-zone Laboratory Tube Furnace

People Also Ask

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition