At its core, chemical vapor deposition (CVD) in semiconductors is a highly controlled process for building ultra-thin, solid films on top of a silicon wafer. It works by introducing specific gases into a reaction chamber, where they chemically react and deposit a layer of material, essentially constructing the microscopic components of a computer chip one atomic layer at a time.

CVD is not merely a coating technique; it is a fundamental fabrication method. It enables the construction of complex, multi-layered semiconductor devices by precisely transforming carefully selected gases into solid, functional films.

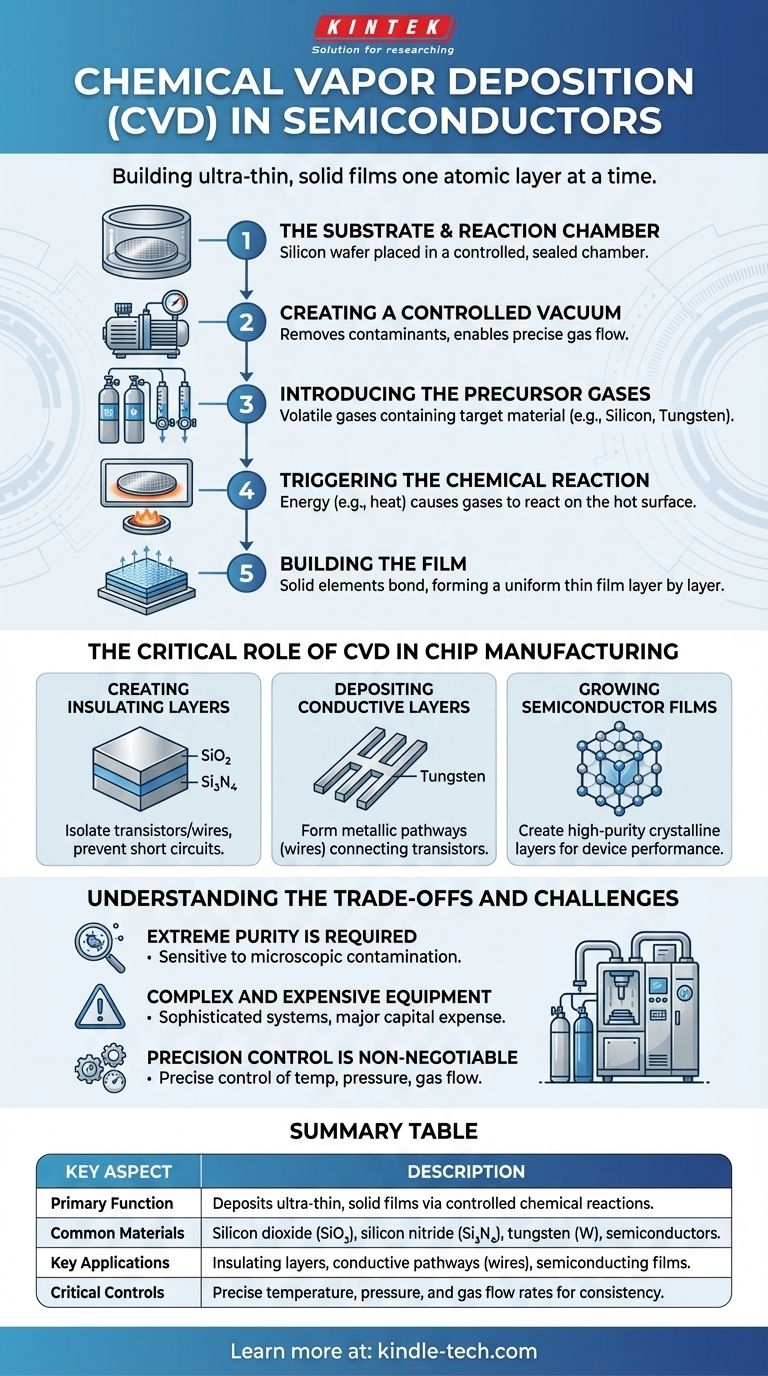

How Chemical Vapor Deposition Works: The Core Mechanism

To understand CVD's importance, you must first understand its fundamental steps. The process is a carefully orchestrated sequence designed for atomic-level precision.

The Substrate and Reaction Chamber

First, the workpiece—typically a silicon wafer—is placed inside a highly controlled, sealed reaction chamber. This chamber is engineered to maintain specific conditions of temperature and pressure.

Creating a Controlled Vacuum

The chamber is put under a vacuum. This step is critical for two reasons: it removes any unwanted atmospheric gases that could contaminate the film, and it allows for the precise control and flow of the reactive gases that will be introduced next.

Introducing the Precursor Gases

A specific mixture of volatile gases, known as precursors, is then introduced into the chamber. These gases contain the atoms of the material you want to deposit, such as silicon, nitrogen, or a metal like tungsten.

Triggering the Chemical Reaction

An energy source, most commonly heat, is applied to the chamber and the wafer. This energy causes the precursor gases to either break down or react with each other on the hot surface of the wafer.

Building the Film

As the gases react, the solid elements bond to the wafer's surface, forming a thin, uniform film. This process continues layer by layer, building the film to a precisely specified thickness across the entire wafer.

The Critical Role of CVD in Chip Manufacturing

CVD is not a single-use process; it's a versatile tool used repeatedly during chip fabrication to build different parts of the integrated circuit.

Creating Insulating Layers

One of the most common uses of CVD is to deposit films of silicon dioxide (SiO₂) or silicon nitride (Si₃N₄). These materials are excellent electrical insulators, used to isolate transistors and wires from each other to prevent short circuits.

Depositing Conductive Layers

CVD is also used to create the metallic pathways that connect the millions or billions of transistors on a chip. Films of materials like tungsten are deposited to act as the "wires" of the circuit.

Growing Semiconductor Films

The process can be used to grow the very semiconductor materials that form the transistors themselves. This allows for the creation of highly pure, crystalline layers with specific electronic properties essential for device performance.

Understanding the Trade-offs and Challenges

While powerful, CVD is a demanding and complex process that requires significant expertise and investment.

Extreme Purity is Required

The process is exceptionally sensitive to contamination. Even microscopic dust particles or trace amounts of unwanted gases can ruin the electronic properties of the deposited film, rendering the chip useless.

Complex and Expensive Equipment

CVD systems are highly sophisticated. They involve integrated gas delivery systems, high-temperature reaction chambers, powerful vacuum pumps, and automated control systems, making the equipment a major capital expense.

Precision Control is Non-Negotiable

The final quality and thickness of the deposited film depend on the precise control of variables like temperature, pressure, and gas flow rates. Maintaining this control consistently across an entire wafer requires a high level of process engineering skill.

How to Apply This to Your Goal

Understanding CVD is essential for anyone involved in electronics or materials science. Your perspective on it will depend on your specific focus.

- If your primary focus is chip fabrication: Recognize CVD as a foundational "additive" manufacturing process, used to build up the critical insulating, conducting, and semiconducting layers of a microchip.

- If your primary focus is materials science: View CVD as a versatile method for creating high-purity, high-performance thin films for a wide range of applications beyond semiconductors, including optics and protective coatings.

- If your primary focus is process engineering: Concentrate on the critical control parameters—temperature, pressure, and gas chemistry—as these are the levers that determine a film's success or failure.

Ultimately, chemical vapor deposition is the invisible engine that enables the atomic-scale construction of the modern electronic world.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Deposits ultra-thin, solid films on silicon wafers via controlled chemical reactions of gases. |

| Common Materials | Silicon dioxide (SiO₂), silicon nitride (Si₃N₄), tungsten (W), and other semiconductors. |

| Key Applications | Creating insulating layers, conductive pathways (wires), and semiconducting transistor films. |

| Critical Controls | Precise temperature, pressure, and gas flow rates for consistent, high-quality results. |

Ready to achieve precision in your lab's thin-film fabrication? KINTEK specializes in high-performance lab equipment and consumables, including solutions for demanding processes like CVD. Whether you're in R&D or production, our expertise ensures you have the reliable tools needed for superior results. Contact our specialists today to discuss how we can support your semiconductor or materials science projects.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vertical Laboratory Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques