In essence, chemical vapor deposition (CVD) for carbon nanotubes (CNTs) is a dominant manufacturing process where a carbon-containing gas is introduced into a high-temperature chamber. The gas decomposes, and the resulting carbon atoms assemble into nanotube structures on a prepared surface, typically with the help of a metal catalyst. This method has become the industrial standard due to its scalability, cost-effectiveness, and ability to control the final product's structure.

CVD is not simply a coating technique; it's a highly controlled, gas-phase chemical reaction. Its core advantage for CNT production is the ability to "grow" nanotubes with specific characteristics at an industrial scale by precisely managing temperature, pressure, and the raw materials involved.

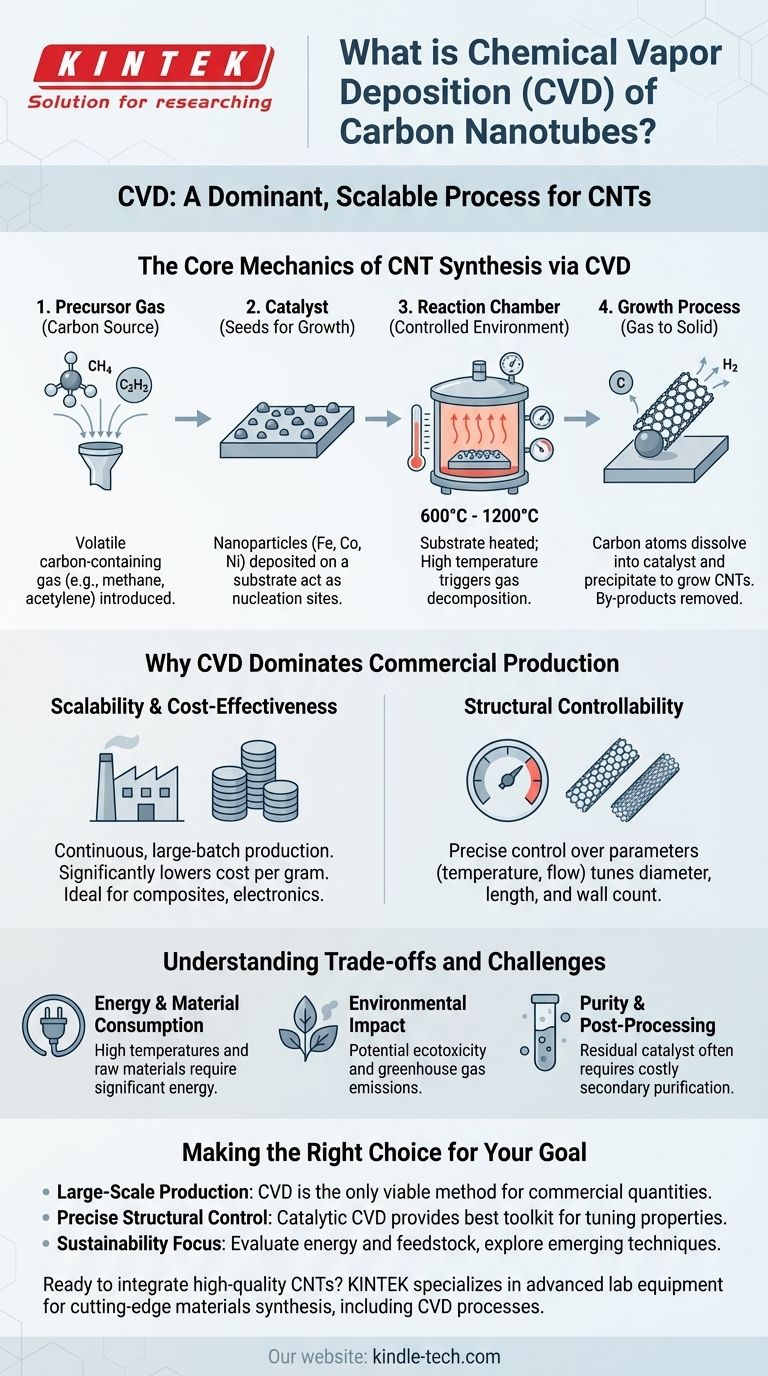

The Core Mechanics of CNT Synthesis via CVD

Chemical vapor deposition is a "bottom-up" approach. Instead of carving a material down, you are building it up atom-by-atom from a chemical vapor.

The Precursor Gas: The Carbon Source

The process begins with a precursor, which is a volatile gas that contains carbon. Common precursors include methane, acetylene, or ethanol.

This gas is injected into the reaction chamber, serving as the raw material from which the carbon nanotubes will be constructed.

The Catalyst: The Seed for Growth

For CNTs, this process is almost always Catalytic CVD (CCVD). Nanoparticles of a metal catalyst, such as iron, cobalt, or nickel, are deposited onto a surface called a substrate.

These tiny metal particles act as the nucleation sites, or "seeds." At high temperatures, they become the active locations where the precursor gas breaks apart and the carbon atoms begin to assemble into the nanotube's hexagonal lattice structure.

The Reaction Chamber: A Controlled Environment

The entire process takes place within a sealed chamber, often under a vacuum or controlled pressure. The substrate is heated to a high reaction temperature, typically between 600°C and 1200°C.

This high temperature provides the necessary energy to trigger the chemical decomposition of the precursor gas on the catalyst's surface.

The Growth Process: From Gas to Solid

As the precursor gas flows over the hot, catalyzed substrate, it decomposes. The carbon atoms dissolve into the catalyst particles and then precipitate out to form the cylindrical, graphene-like walls of a carbon nanotube.

Volatile by-products from the reaction, such as hydrogen gas, are continuously removed from the chamber by a steady gas flow, leaving behind a solid layer or powder of high-purity CNTs.

Why CVD Dominates Commercial Production

While older methods like arc discharge and laser ablation can produce high-quality CNTs, they are difficult to scale. CVD has emerged as the clear leader for industrial applications.

Scalability and Cost-Effectiveness

CVD systems can be designed for continuous or large-batch production, drastically lowering the cost per gram of CNTs compared to other methods. This makes their use in composites, electronics, and batteries economically feasible.

Structural Controllability

CVD offers a remarkable degree of control over the final product. By carefully tuning the parameters—such as temperature, pressure, gas flow rate, and the size of the catalyst particles—manufacturers can influence the nanotubes' diameter, length, and whether they are single-walled or multi-walled.

Understanding the Trade-offs and Challenges

Despite its advantages, the CVD process is not without its challenges. Objectivity requires acknowledging its limitations.

Energy and Material Consumption

The high temperatures required for the reaction demand a significant amount of energy, which is a primary driver of both cost and environmental footprint. The precursors and catalyst materials also contribute to the overall resource consumption.

Environmental Impact

The synthesis process itself is the main source of potential ecotoxicity. Concerns include greenhouse gas emissions from heating and the chemical by-products generated during the reaction.

Purity and Post-Processing

The CNTs produced via CVD can contain impurities, most commonly residual catalyst particles trapped within or on the nanotubes. These impurities often must be removed through secondary purification steps, adding complexity and cost to the overall process.

Making the Right Choice for Your Goal

Understanding the fundamentals of CVD allows you to assess its suitability for specific applications.

- If your primary focus is large-scale production: CVD is the only proven and economically viable method for producing CNTs in the quantities required for commercial products.

- If your primary focus is precise structural control: Catalytic CVD provides the most effective toolkit for tuning nanotube properties like diameter and wall number by adjusting the synthesis parameters.

- If your primary focus is sustainability: You must critically evaluate the energy consumption and feedstock source, looking toward emerging CVD techniques that utilize waste streams or captured carbon dioxide.

By grasping the principles of CVD, you can better evaluate CNT quality and production methods based on the fundamental trade-offs between cost, control, and environmental impact.

Summary Table:

| Key Element | Role in CVD Process |

|---|---|

| Precursor Gas | Provides the carbon source (e.g., methane, acetylene). |

| Metal Catalyst | Acts as a seed for nanotube growth (e.g., iron, cobalt). |

| Reaction Chamber | Provides a controlled high-temperature environment (600-1200°C). |

| Growth Process | Carbon atoms dissolve and precipitate from the catalyst to form CNTs. |

Ready to integrate high-quality carbon nanotubes into your research or product development? KINTEK specializes in providing the advanced lab equipment and consumables necessary for cutting-edge materials synthesis, including CVD processes. Our expertise can help you achieve precise control and scalability in your nanotube production. Contact our team today to discuss how we can support your laboratory's specific needs and accelerate your innovation.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth