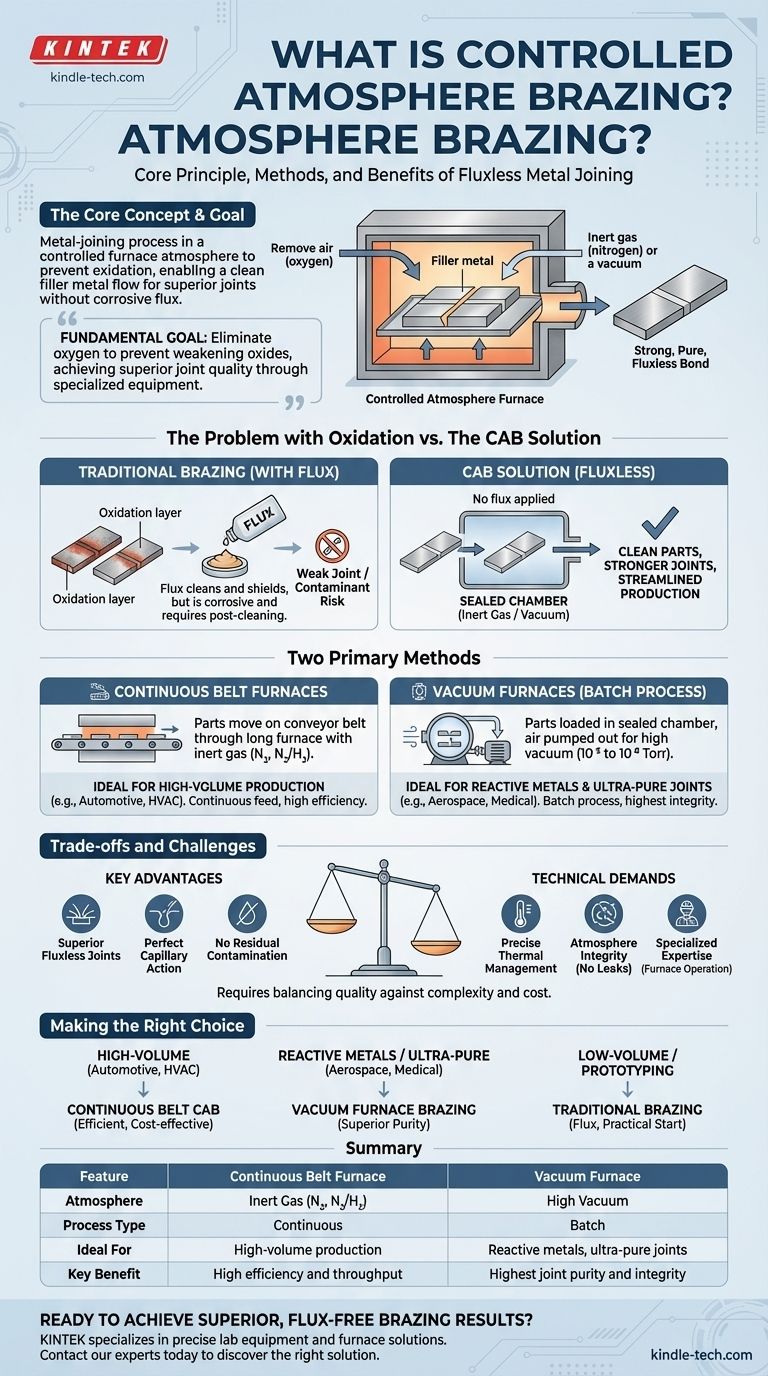

At its core, controlled atmosphere brazing (CAB) is a metal-joining process that takes place inside a furnace where the atmosphere is carefully managed to prevent oxidation. By removing oxygen and using an inert gas like nitrogen or creating a vacuum, CAB allows a filler metal to flow cleanly between two parts, creating an exceptionally strong and pure bond without the need for corrosive chemical fluxes.

The fundamental goal of controlled atmosphere brazing is to achieve superior joint quality by eliminating oxygen from the process. This prevents the formation of oxides that weaken the bond, but it requires specialized equipment and precise control over temperature and atmospheric conditions.

The Core Principle: Why Control the Atmosphere?

When metals are heated to high temperatures in the presence of normal air, they react with oxygen. This process, called oxidation, creates a layer on the metal surface that can prevent the filler material from bonding properly, resulting in a weak or failed joint.

The Problem with Oxidation

Oxidation acts as a contaminant. In traditional brazing, this is managed by applying a chemical agent called flux, which cleans the surface and shields it from oxygen during heating.

However, flux itself can be problematic. It is often corrosive and must be completely cleaned from the part after brazing, which adds an extra, difficult step to the manufacturing process.

The CAB Solution: Remove the Oxygen

Controlled atmosphere brazing solves this problem by removing the oxygen from the environment altogether. By conducting the process in a sealed chamber filled with an inert gas or in a vacuum, there is no oxygen to cause oxidation.

This fluxless process results in cleaner parts, stronger joints, and a more streamlined production workflow, as the post-braze flux cleaning step is eliminated.

Two Primary Methods for Controlling the Atmosphere

The "controlled atmosphere" can be achieved in two main ways, each suited for different production needs. The choice between them depends on factors like production volume, the type of metals being joined, and the required purity of the final joint.

Continuous Belt Furnaces

In this method, parts are placed on a conveyor belt that moves them through a long furnace. The furnace is filled with an inert gas, typically oxygen-free nitrogen or a nitrogen-hydrogen mix, which purges the air.

This process is highly efficient for high-volume production, such as in the automotive and HVAC industries, as parts are continuously fed through the heating and cooling zones.

Vacuum Furnaces (Batch Process)

For this method, parts are loaded into a sealed chamber. All the air is then pumped out to create a high-vacuum environment (typically in the 10⁻⁵ to 10⁻⁶ Torr range).

Once the vacuum is achieved, the furnace heats the parts to the brazing temperature. This process is ideal for reactive metals (like titanium) or for applications in aerospace and medical devices where the absolute highest purity and joint integrity are required. It is a batch process, meaning one load is completed at a time.

Understanding the Trade-offs and Key Challenges

While CAB offers significant advantages, it is a technically demanding process that involves specific challenges and considerations. The decision to use it requires balancing the need for quality against the complexity and cost of the equipment.

The Key Advantage: Superior, Fluxless Joints

The primary benefit is the ability to create extremely clean, strong, and reliable joints. The controlled environment prevents localized overheating, allows the filler metal to flow perfectly via capillary action, and produces a finished assembly with no residual flux contamination.

The Technical Demands

Success with CAB requires specialized knowledge. Key challenges include:

- Filler Material Selection: The filler must have a lower melting point than the base metals and be compatible with the application's strength and conductivity requirements.

- Precise Thermal Management: The furnace must be able to heat parts to the correct temperature for the right amount of time to ensure the filler melts and flows without damaging the base metals.

- Atmosphere Integrity: Maintaining the purity of the nitrogen atmosphere or the integrity of the vacuum is critical. Leaks can introduce oxygen and compromise the entire batch.

- Specialized Expertise: The process demands technical knowledge of furnace operation, industrial gas handling, and the metallurgical principles of brazing.

Making the Right Choice for Your Goal

Selecting the right brazing method depends entirely on your project's technical requirements, production volume, and budget.

- If your primary focus is high-volume production of components like automotive radiators or HVAC parts: Continuous belt CAB is the most efficient and cost-effective method.

- If your primary focus is joining reactive metals or creating ultra-pure joints for aerospace or medical applications: Vacuum furnace brazing is the superior, and often necessary, choice.

- If your primary focus is low-volume assembly or prototyping without high capital investment: Traditional torch or induction brazing with flux may be a more practical starting point.

Ultimately, choosing controlled atmosphere brazing is an investment in achieving the highest possible joint quality and process repeatability.

Summary Table:

| Feature | Continuous Belt Furnace | Vacuum Furnace |

|---|---|---|

| Atmosphere | Inert Gas (N₂, N₂/H₂) | High Vacuum |

| Process Type | Continuous | Batch |

| Ideal For | High-volume production (e.g., automotive, HVAC) | Reactive metals, ultra-pure joints (e.g., aerospace, medical) |

| Key Benefit | High efficiency and throughput | Highest joint purity and integrity |

Ready to achieve superior, flux-free brazing results?

KINTEK specializes in the precise lab equipment and furnace solutions needed for successful controlled atmosphere brazing. Whether you're in high-volume manufacturing or developing high-purity components for aerospace and medical applications, our expertise ensures you get the strong, clean, and reliable joints your projects demand.

Contact our brazing experts today to discuss your specific needs and discover the right solution for your laboratory or production line.

Visual Guide

Related Products

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is an atmosphere furnace required for Carbon-based Solid Acid Catalysts? Mastering Incomplete Carbonization

- What role does an inert gas-protected heating device play in 2024Al/Gr/SiC composite manufacturing?

- What key processing conditions does a tubular atmosphere furnace provide? Unlock Cr/SZ Catalyst Performance

- Why is an atmosphere control high-temperature furnace required for MoS2 & graphene? Achieve Peak Material Performance

- Why is a precisely controlled high-temperature furnace with steam or air atmospheres required? Engineering Alpha-Alumina

- What is the function of a high-temperature atmosphere furnace in the carbonization of cellulose waste? Expert Guide

- What role does an atmosphere sintering furnace play in nickel catalyst SMSI? Optimize Metal-Support Interaction

- Why does argon displace oxygen? The Silent Danger of a Denser Gas