In dental technology, a dental ceramic furnace is a specialized, high-temperature oven designed for processing dental prosthetics. Its purpose is to fire or sinter ceramic materials like crowns, veneers, inlays, and bridges, transforming them from a fragile pre-sintered state into a hard, durable, and aesthetically pleasing final restoration. This precisely controlled heating process is what gives the ceramic its final strength, fit, and color.

A dental furnace is not merely an oven; it is a precision instrument at the heart of the dental lab. The quality and accuracy of the furnace directly determine the clinical success, aesthetic outcome, and longevity of the final ceramic restoration.

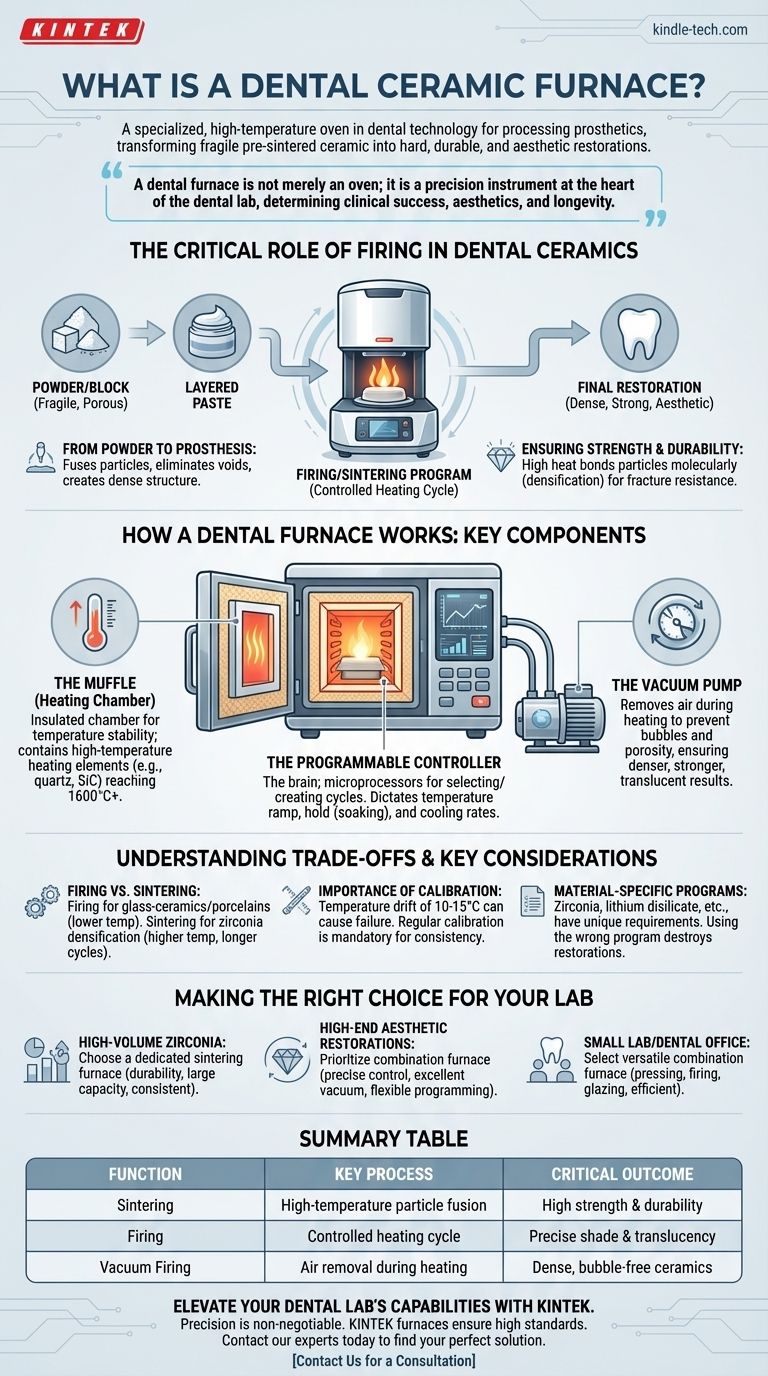

The Critical Role of Firing in Dental Ceramics

A dental furnace orchestrates a material transformation that is essential for modern dentistry. Without this controlled heating process, advanced ceramics would be unusable for restorations.

From Powder to Prosthesis

Most dental ceramics begin as a compacted powder, a milled "green state" block, or a layered paste. In this initial form, the material is chalky, porous, and extremely fragile.

The furnace applies a specific heating cycle, known as a firing or sintering program. This process fuses the ceramic particles together, eliminating voids and creating a dense, monolithic structure.

Achieving Lifelike Aesthetics

The firing cycle is critical for achieving the final shade and translucency of the restoration. The furnace's controller precisely manages the temperature ramp-up, hold time, and cooling rate.

This control allows technicians to develop the material's intrinsic optical properties, such as opalescence and fluorescence, enabling the final crown or veneer to mimic a natural tooth seamlessly.

Ensuring Strength and Durability

The primary function of sintering is to impart strength. The high heat causes the ceramic particles to bond on a molecular level, a process called densification.

A properly sintered restoration is incredibly strong and resistant to fracture, capable of withstanding the immense chewing forces exerted in the mouth for years.

How a Dental Furnace Works: Key Components

Understanding the core components of a furnace reveals why precision is so vital. Each part plays a specific role in achieving a predictable and successful outcome.

The Muffle (Heating Chamber)

The muffle is the insulated chamber where the restoration is placed. It is lined with high-quality insulation to ensure temperature stability and uniformity.

Inside the muffle are heating elements, often made of quartz or silicon carbide, which generate the extreme temperatures required for sintering, sometimes exceeding 1600°C (2900°F).

The Programmable Controller

This is the brain of the furnace. Modern controllers are microprocessors that allow technicians to select pre-set programs for specific materials or create custom firing cycles.

The controller dictates every stage of the process: the rate of temperature increase, how long the temperature is held (soaking), and the rate of cooling. Inaccuracy here can ruin the restoration.

The Vacuum Pump

For many porcelain and glass-ceramic materials, firing under a vacuum is essential. An external vacuum pump connects to the muffle and removes air from the chamber during the heating cycle.

This prevents air from being trapped within the ceramic, which would cause bubbles, porosity, and a cloudy appearance. A vacuum results in a denser, stronger, and more translucent restoration.

Understanding the Trade-offs and Key Considerations

While the concept is simple, the execution is complex. Several factors can mean the difference between a perfect restoration and a complete failure.

Firing vs. Sintering

While often used interchangeably, these terms have nuances. Firing typically refers to the process for glass-ceramics and layered porcelains, often at lower temperatures.

Sintering specifically refers to the high-temperature densification of zirconia frameworks. Sintering furnaces are built to handle higher temperatures and longer cycles than traditional porcelain furnaces. Many modern units are combination furnaces capable of both.

The Importance of Calibration

A furnace's temperature reading can drift over time. A furnace that is off by even 10-15 degrees can cause a restoration to be under-fired (weak) or over-fired (distorted, glassy).

Regular calibration using standardized materials is mandatory to ensure the temperature displayed on the controller is the actual temperature inside the muffle. This guarantees consistent and predictable results.

Material-Specific Programs

Different ceramics—zirconia, lithium disilicate, feldspathic porcelain—have vastly different firing requirements. Using the wrong program will destroy the restoration.

A reliable furnace must execute these unique programs with absolute fidelity. The ability to customize programs is also crucial for advanced technicians who want to fine-tune aesthetic outcomes.

Making the Right Choice for Your Lab

Selecting a furnace depends entirely on the type of work your laboratory specializes in.

- If your primary focus is high-volume zirconia production: You need a dedicated sintering furnace known for its durability, large capacity, and consistent performance over long heating cycles.

- If your primary focus is high-end aesthetic restorations: Prioritize a combination furnace with exceptionally precise temperature control, an excellent vacuum system, and flexible programming for layering custom porcelains.

- If you are a smaller lab or a dental office with an in-house lab: A versatile and reliable combination furnace that can handle pressing, firing, and glazing is the most efficient and cost-effective investment.

Ultimately, investing in the right dental furnace is an investment in the quality, consistency, and reputation of your work.

Summary Table:

| Function | Key Process | Critical Outcome |

|---|---|---|

| Sintering | High-temperature particle fusion | High strength & durability |

| Firing | Controlled heating cycle | Precise shade & translucency |

| Vacuum Firing | Air removal during heating | Dense, bubble-free ceramics |

Elevate Your Dental Lab's Capabilities with KINTEK

Precision is non-negotiable in dental ceramics. The right furnace ensures every crown, veneer, and bridge you produce meets the highest standards of strength, fit, and aesthetics. KINTEK specializes in high-performance lab equipment, including reliable dental ceramic furnaces designed for accuracy and consistency.

Whether you specialize in high-volume zirconia sintering or intricate layered porcelain work, our solutions are engineered to support your success. Contact our experts today to find the perfect furnace for your specific needs and ensure the longevity and reputation of your restorations.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

People Also Ask

- What is one of the newest applications for dental ceramics? Monolithic Zirconia for Full-Arch Bridges

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics