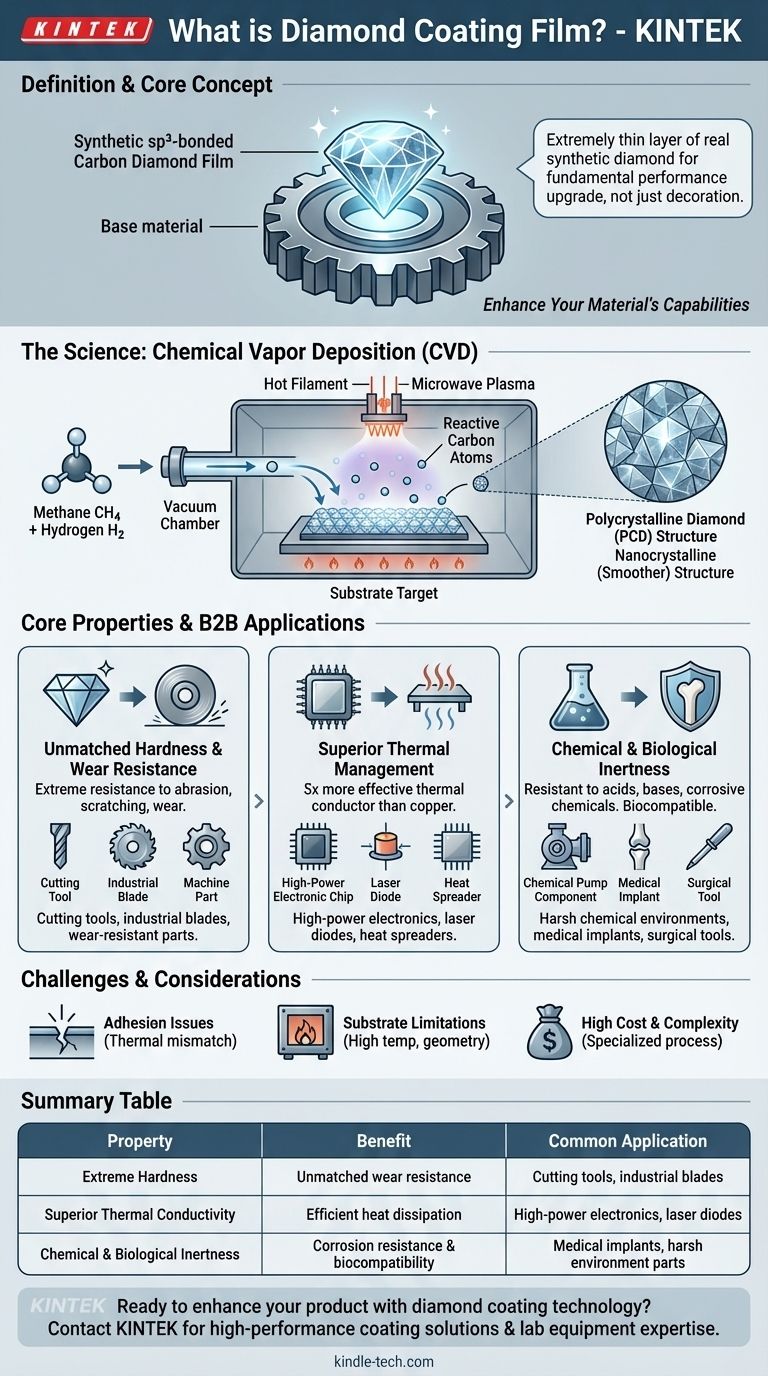

In short, a diamond coating film is an extremely thin layer of real, synthetically grown diamond deposited onto the surface of another material. This is not a diamond-like paint or imitation; it is a film composed of sp³-bonded carbon atoms, the exact same crystal structure that gives natural diamonds their legendary properties. The purpose is to impart these properties—primarily extreme hardness, thermal conductivity, and chemical inertness—to a base material like metal, ceramic, or silicon.

The core idea behind diamond film is not to add decorative value, but to fundamentally upgrade a material's performance. By applying a micro-thin layer of synthetic diamond, you can create a composite material that performs tasks far beyond the capability of the original substrate alone.

The Science Behind Diamond Film: More Than Just a Coating

Understanding diamond film requires looking past the surface and into the atomic-level engineering that makes it possible. It is a product of advanced materials science designed to solve specific engineering challenges.

How It's Made: Chemical Vapor Deposition (CVD)

The primary method for creating diamond film is Chemical Vapor Deposition (CVD).

Think of this process as "growing" a diamond film atom-by-atom. A substrate (the object to be coated) is placed in a vacuum chamber, which is then filled with a carbon-containing gas (like methane) and hydrogen.

High energy is introduced—either via a hot filament or microwave plasma—to break apart the gas molecules. This creates a cloud of reactive carbon atoms that then settle, or "deposit," onto the substrate, arranging themselves into the rigid, interlocking crystal lattice of diamond.

The Different "Flavors" of Diamond Film

Not all diamond films are identical. The specific conditions of the CVD process can be tuned to create different structures for different applications.

The most common is Polycrystalline Diamond (PCD) film. This consists of many small, randomly oriented diamond crystals that are interlocked, providing exceptional hardness.

Other variations, like Nanocrystalline Diamond, have much smaller grain sizes, resulting in a smoother and more uniform surface, which is beneficial for low-friction or optical applications.

Why Use Diamond Coating? Core Properties and Applications

The decision to use a diamond coating is driven by its ability to solve problems that other materials cannot. Its value comes from a unique combination of extreme properties.

Unmatched Hardness and Wear Resistance

Diamond is the hardest known material. When applied as a film, it creates a surface that is incredibly resistant to abrasion, scratching, and wear.

This is critical for cutting tools (for machining non-ferrous metals, composites, and ceramics), industrial blades, and wear-resistant parts in machinery, dramatically extending their operational life.

Superior Thermal Management

Diamond is also the best-known thermal conductor at room temperature—about five times more effective than copper. It excels at pulling heat away from a source.

This property is revolutionary for high-power electronics and laser diodes. A diamond film can act as a "heat spreader," preventing critical components from overheating and enabling higher performance and miniaturization.

Extreme Chemical and Biological Inertness

Diamond does not react with most acids, bases, or corrosive chemicals. It is also biocompatible, meaning the human body does not typically have an adverse reaction to it.

This makes it ideal for protecting components in harsh chemical environments and for use in medical implants (like joint replacements) and advanced surgical tools, where durability and non-reactivity are paramount.

Understanding the Trade-offs and Challenges

While its properties are exceptional, diamond film technology is not a universal solution. There are significant engineering challenges and limitations to consider.

The Challenge of Adhesion

One of the biggest hurdles is getting the diamond film to stick firmly to the substrate. Diamond and most substrate materials (like steel or titanium) have very different rates of thermal expansion.

When the coated part heats up or cools down, this mismatch can create immense internal stress, causing the diamond film to crack or peel off. Significant research is dedicated to creating intermediate bonding layers to solve this.

Substrate and Geometry Limitations

The high temperatures required for the CVD process (often over 700°C) limit the types of materials that can be coated. Most plastics and low-melting-point metals cannot survive the process.

Furthermore, CVD is a "line-of-sight" process, which can make it difficult to uniformly coat complex, three-dimensional shapes with internal cavities or sharp corners.

Cost and Complexity

Diamond coating is a highly specialized and expensive process. The CVD reactors represent a significant capital investment, and the process requires precise control and expertise.

Because of this, its use is typically reserved for high-value applications where the performance improvement justifies the significant cost.

Making the Right Choice for Your Goal

Deciding whether to use diamond film requires matching its unique benefits to a specific performance goal.

- If your primary focus is extending tool life for cutting composites or non-ferrous metals: Diamond-coated tools offer a dramatic increase in wear resistance and are often the industry standard.

- If your primary focus is managing heat in dense, high-power electronics: Diamond film is an unparalleled material for heat spreaders to improve thermal reliability.

- If your primary focus is creating highly durable, biocompatible medical devices: The inertness and hardness of diamond film make it a leading candidate for next-generation implants and surgical instruments.

- If your primary focus is protecting sensors or components in a corrosive environment: A diamond film can serve as the ultimate protective barrier where other coatings would fail.

By understanding its capabilities and limitations, you can leverage diamond film not just as a coating, but as a fundamental design tool to achieve performance previously thought impossible.

Summary Table:

| Property | Benefit | Common Application |

|---|---|---|

| Extreme Hardness | Unmatched wear resistance | Cutting tools, industrial blades |

| Superior Thermal Conductivity | Efficient heat dissipation | High-power electronics, laser diodes |

| Chemical & Biological Inertness | Corrosion resistance & biocompatibility | Medical implants, harsh environment parts |

Ready to enhance your product's performance with diamond coating technology?

At KINTEK, we specialize in advanced lab equipment and consumables, including solutions for high-performance coatings. Whether you're developing cutting tools, thermal management systems for electronics, or durable medical devices, our expertise can help you leverage diamond film's unique properties.

Contact us today to discuss how we can support your laboratory's innovation and application needs!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Laboratory CVD Boron Doped Diamond Materials

- Evaporation Boat for Organic Matter

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

People Also Ask

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer