In practice, there is no difference; the terms "IR" and "FTIR" are often used interchangeably to refer to the same modern analytical technique. However, the correct term for virtually all modern infrared spectroscopy is FTIR. The distinction lies not in the underlying principle of infrared absorption, but in the instrumentation used to acquire the spectrum.

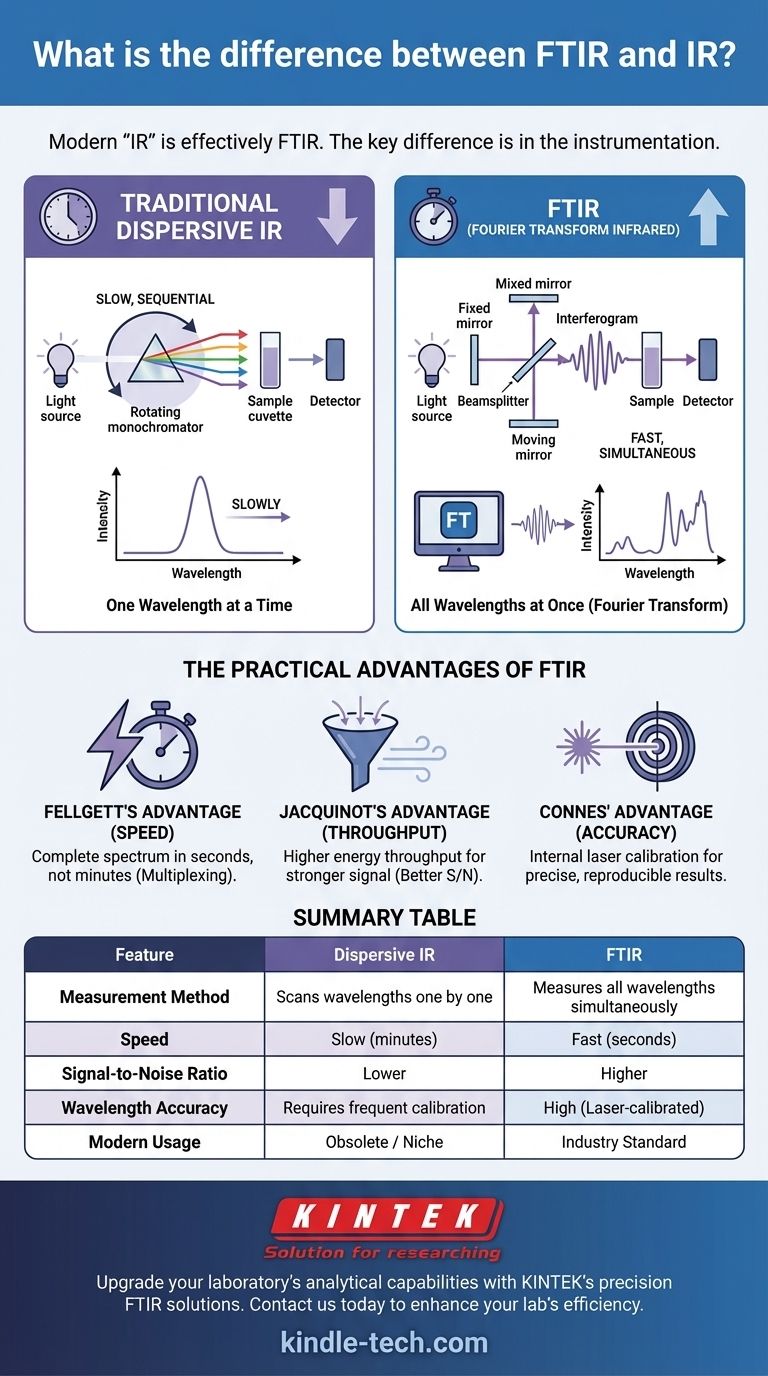

The core difference is this: traditional "IR" used a dispersive monochromator to scan through wavelengths one by one, while "FTIR" (Fourier Transform Infrared Spectroscopy) uses an interferometer to measure all wavelengths simultaneously, resulting in a massive improvement in speed, sensitivity, and accuracy.

The Core Distinction: How the Spectrum is Measured

The fundamental innovation of FTIR is a complete change in the optical design and data processing, moving from a slow, sequential process to a fast, simultaneous one.

Traditional Dispersive IR: One Wavelength at a Time

Older instruments, properly called dispersive infrared spectrophotometers, worked much like a prism splitting white light into a rainbow.

A grating or prism (a monochromator) would rotate to select and pass one specific wavelength of IR light at a time through the sample to a detector. The instrument would slowly scan across the entire wavelength range, measuring the intensity point-by-point to build the spectrum.

This process is mechanically slow and optically inefficient, as most of the energy from the light source is blocked at any given moment.

FTIR: All Wavelengths at Once

FTIR spectrometers replaced the monochromator with a device called an interferometer, most commonly a Michelson interferometer.

Instead of filtering light, an interferometer splits the IR beam, sends it down two different paths, and then recombines it. This creates a complex interference pattern called an interferogram, which contains information about all wavelengths simultaneously.

This entire packet of encoded light passes through the sample and hits the detector at once.

The Role of the Fourier Transform

The interferogram measured by the detector is a signal plotted over time (or mirror displacement). It does not look like a typical spectrum.

A computer then applies a mathematical algorithm called the Fourier Transform (the "FT" in FTIR) to the interferogram. This calculation instantly decodes the interference pattern, converting it from the time domain into the familiar frequency domain, which gives us the final spectrum of absorbance vs. wavenumber.

The Practical Advantages of the FTIR Method

The move from a dispersive to an FTIR design was not a minor upgrade; it was a revolutionary leap that produced several critical, named advantages. These benefits are why FTIR completely replaced older methods.

Fellgett's Advantage (The Multiplex Advantage)

This is the most significant benefit. By measuring all frequencies at the same time (multiplexing), an FTIR instrument can acquire a complete spectrum in seconds. A dispersive instrument would take many minutes to acquire a spectrum of similar quality. This dramatically increases sample throughput.

Jacquinot's Advantage (The Throughput Advantage)

Dispersive instruments require narrow slits to ensure only a single wavelength reaches the sample, which throws away a significant amount of light energy. An interferometer has a large, circular aperture, allowing much more of the IR source's energy to pass through the instrument and sample.

This higher energy throughput results in a much stronger signal at the detector, leading to a higher signal-to-noise ratio (S/N). This makes FTIR far more sensitive, allowing for the analysis of very small samples or weakly absorbing materials.

Connes' Advantage (The Wavelength Accuracy Advantage)

FTIR instruments include a helium-neon (HeNe) laser as an internal wavelength calibration standard. The interferometer uses the laser's single, known wavelength to precisely track the position of the moving mirror.

This continuous calibration ensures the wavenumber (x-axis) of the spectrum is extremely accurate and reproducible from scan to scan and instrument to instrument. Dispersive instruments were prone to mechanical slippage and required frequent, cumbersome recalibration.

Why You Almost Never See Dispersive IR Today

The transition from dispersive IR to FTIR was driven by computing. The theory of interferometry was known for a century, but performing the Fourier Transform calculation was too slow and expensive for routine use.

The Rise of FTIR

The development of affordable microcomputers in the 1970s and 1980s made it possible to perform the Fast Fourier Transform (FFT) algorithm nearly instantly. This unlocked the practical potential of the FTIR design, and the technique quickly dominated the field due to its overwhelming advantages in speed and sensitivity.

The Status of Dispersive IR

Today, dispersive IR instruments are essentially obsolete for general analytical chemistry. You might find them in museums, older teaching labs, or a few highly specialized niche applications. For all intents and purposes, when a chemist refers to running an "IR," they mean they are using an FTIR spectrometer.

Making the Right Choice in Terminology

Understanding this history helps you communicate with precision. While the terms are often used interchangeably in casual conversation, being specific shows a deeper understanding.

- If your primary focus is modern chemical analysis: Use "FTIR" to be technically accurate, as this describes the instrumentation used in every modern lab.

- If you are speaking generally about the theory of molecular vibrations: "IR spectroscopy" is a perfectly acceptable umbrella term that encompasses the entire field, including FTIR.

- If you are reading scientific literature from before ~1985: Be aware that a reference to "IR spectroscopy" almost certainly describes data collected on a slower, lower-resolution dispersive instrument.

Ultimately, knowing the difference between IR and FTIR is understanding the technological leap that transformed infrared analysis from a slow, specialized method into a fast, powerful, and routine tool for modern science.

Summary Table:

| Feature | Traditional Dispersive IR | Modern FTIR |

|---|---|---|

| Measurement Method | Scans wavelengths one by one | Measures all wavelengths simultaneously |

| Speed | Slow (minutes per scan) | Fast (seconds per scan) |

| Signal-to-Noise Ratio | Lower | Higher (Throughput Advantage) |

| Wavelength Accuracy | Requires frequent calibration | High (Laser-calibrated) |

| Modern Usage | Obsolete / Niche applications | Industry standard |

Upgrade your laboratory's analytical capabilities with KINTEK's precision FTIR solutions.

As a leading provider of lab equipment and consumables, KINTEK specializes in delivering cutting-edge FTIR spectrometers that offer the speed, sensitivity, and accuracy modern laboratories demand. Whether you're analyzing materials, conducting quality control, or advancing research, our instruments provide the reliable performance you need.

Contact us today to discuss how KINTEK's FTIR technology can enhance your laboratory's efficiency and analytical power. Let our experts help you select the perfect solution for your specific application needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

People Also Ask

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution