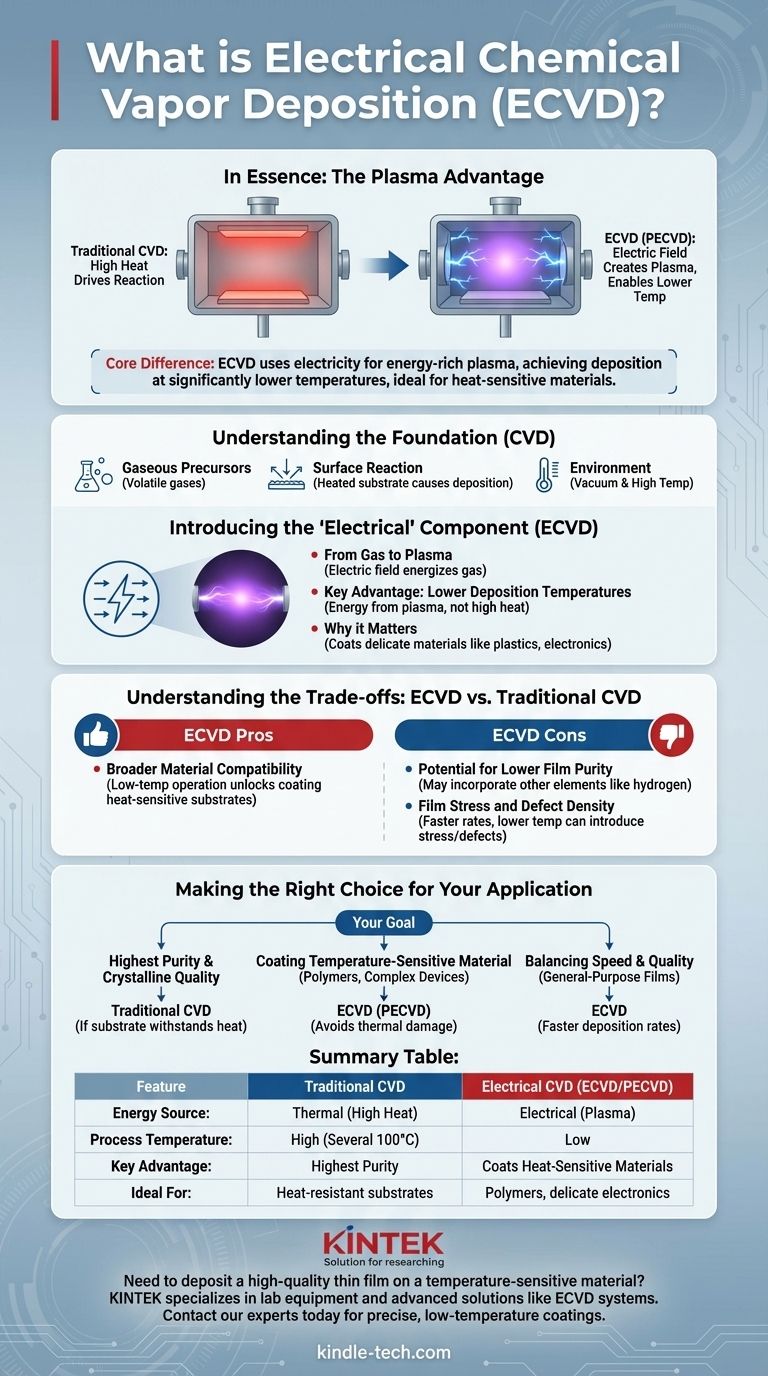

In essence, Electrical Chemical Vapor Deposition (ECVD) is a specialized form of chemical vapor deposition that uses an electric field to create a plasma. This plasma energizes the precursor gases, allowing the deposition of high-quality thin films onto a surface at significantly lower temperatures than traditional CVD methods.

The core difference is simple: while traditional CVD relies solely on high heat to drive chemical reactions, ECVD uses electricity to create an energy-rich plasma, achieving the same result without extreme temperatures. This makes it ideal for coating heat-sensitive materials.

Understanding the Foundation: What is Chemical Vapor Deposition (CVD)?

To understand ECVD, you must first grasp the principles of standard Chemical Vapor Deposition (CVD). It is a foundational process for creating ultra-thin, high-performance solid layers on a substrate.

The Core Principle: Gaseous Precursors

The process begins by introducing one or more volatile precursor gases into a reaction chamber. These gases contain the chemical elements that will form the final coating.

The Deposition Process: A Reaction on a Surface

Inside the chamber, the substrate (the workpiece to be coated) is heated. This thermal energy causes the precursor gases to react or decompose on the substrate's surface, depositing a solid thin film.

The Environment: Vacuum and Temperature

This entire process occurs in a vacuum under tightly controlled conditions. The vacuum ensures purity, while high temperatures—often several hundred degrees Celsius—provide the necessary energy to initiate the chemical reaction.

Introducing the "Electrical" Component: How ECVD Works

Electrical Chemical Vapor Deposition, more commonly known as Plasma-Enhanced Chemical Vapor Deposition (PECVD), fundamentally alters the energy source for the reaction.

From Gas to Plasma: The Role of the Electric Field

Instead of relying only on heat, ECVD applies a strong electric field to the precursor gases within the chamber. This field energizes the gas, stripping electrons from the atoms and creating a plasma—a highly reactive state of matter.

The Key Advantage: Lower Deposition Temperatures

Because the plasma is already in a high-energy, reactive state, the deposition process no longer requires extreme heat. The energy for the reaction comes from the electrically-charged plasma itself, not from heating the substrate to high temperatures.

Why Lower Temperatures Matter

This is the primary driver for using ECVD. It allows for the deposition of thin films on materials that cannot withstand the high heat of traditional CVD, such as plastics, certain semiconductors, and other delicate electronic components.

Understanding the Trade-offs: ECVD vs. Traditional CVD

Choosing between traditional CVD and its plasma-enhanced variant involves a clear set of trade-offs related to temperature, quality, and application.

Pro: Broader Material Compatibility

ECVD's low-temperature operation is its greatest strength. It unlocks the ability to coat heat-sensitive substrates that would be damaged or destroyed by the conditions in a standard CVD process.

Con: Potential for Lower Film Purity

The plasma process can sometimes lead to the incorporation of other elements, like hydrogen, into the deposited film. This can make the resulting film less pure than one produced by high-temperature thermal CVD.

Con: Film Stress and Defect Density

While deposition rates can be faster, the lower temperature and plasma environment can sometimes introduce internal stress or a higher density of defects into the film's crystalline structure compared to the slow, methodical growth in a thermal CVD process.

Making the Right Choice for Your Application

Your specific goal determines which method is superior. The decision is not about which process is "better" overall, but which is the right tool for the job.

- If your primary focus is the highest possible film purity and crystalline quality: Traditional high-temperature CVD is often the superior choice, provided your substrate can withstand the heat.

- If your primary focus is coating a temperature-sensitive material like a polymer or a complex microelectronic device: ECVD (or PECVD) is the necessary and correct approach, as it avoids thermal damage.

- If your primary focus is balancing speed with quality for general-purpose films: ECVD can offer faster deposition rates, making it a more economical choice for certain industrial applications.

Ultimately, understanding the role of energy—thermal versus electrical—is the key to mastering these powerful deposition techniques.

Summary Table:

| Feature | Traditional CVD | Electrical CVD (ECVD/PECVD) |

|---|---|---|

| Energy Source | Thermal (High Heat) | Electrical (Plasma) |

| Process Temperature | High (Several 100°C) | Low |

| Key Advantage | Highest Film Purity & Quality | Coats Heat-Sensitive Materials |

| Ideal For | Substrates that can withstand high heat | Polymers, delicate electronics, complex devices |

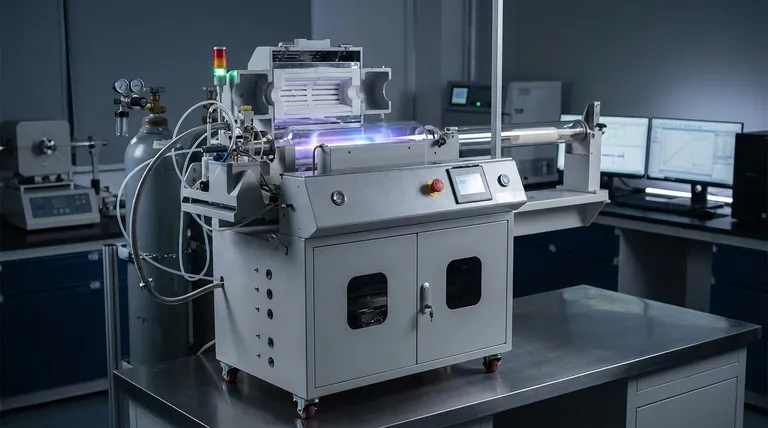

Need to deposit a high-quality thin film on a temperature-sensitive material? KINTEK specializes in lab equipment and consumables, serving laboratory needs with advanced solutions like ECVD systems. Our expertise ensures you achieve precise, low-temperature coatings without compromising on performance. Contact our experts today to find the perfect deposition solution for your application!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Spark Plasma Sintering Furnace SPS Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What are the methods of producing CNT? Scalable CVD vs. High-Purity Lab Techniques

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision