At its core, fluidized bed pyrolysis is a highly efficient thermal decomposition process. It works by feeding organic materials, like biomass or plastic, into a reactor containing a bed of hot, sand-like particles that are agitated by a flow of inert gas, typically nitrogen. This "fluidized" bed behaves like a boiling liquid, ensuring extremely rapid and uniform heat transfer to the material, breaking it down into valuable products in the complete absence of oxygen.

The central advantage of fluidized bed pyrolysis is its superior heat transfer capability. This rapid heating maximizes the yield of liquid bio-oil and minimizes less desirable byproducts, making it a leading technology for converting solid waste into liquid fuels.

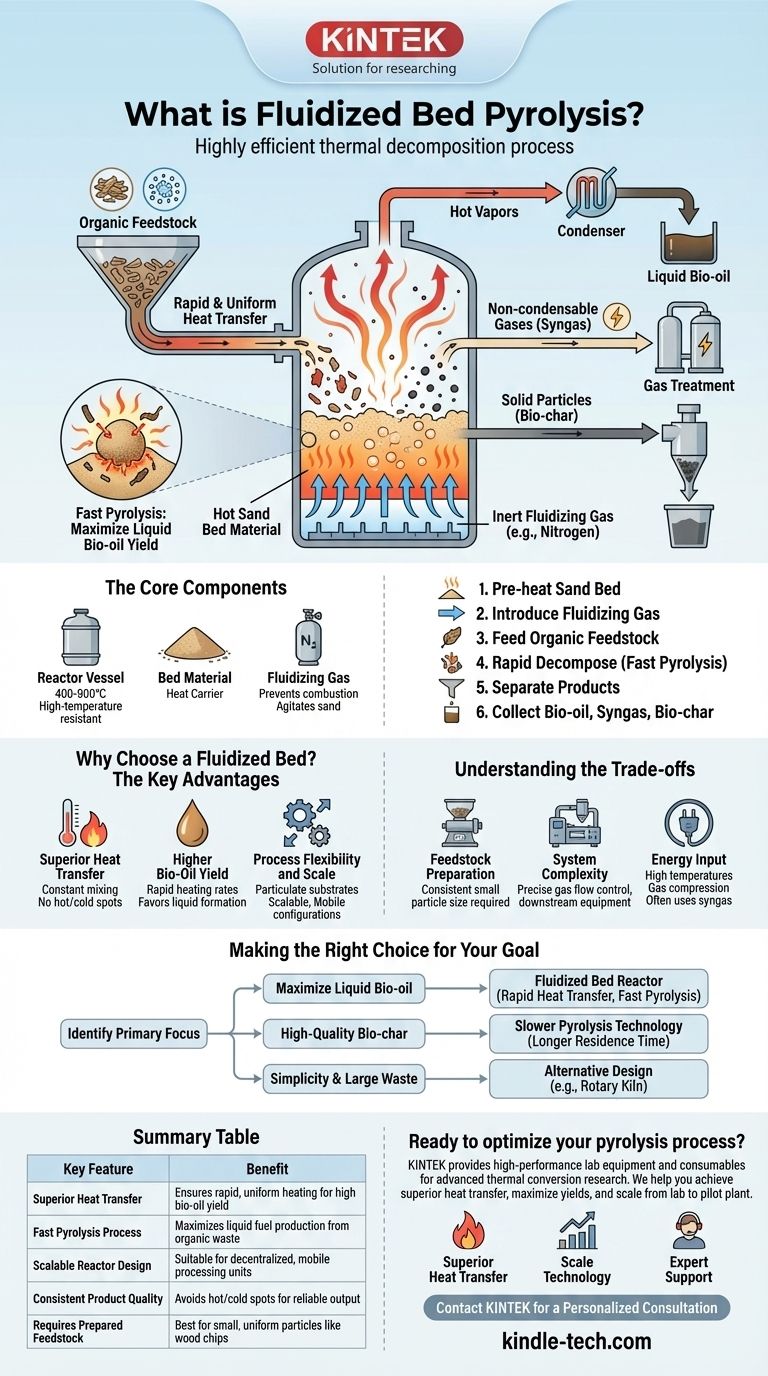

How a Fluidized Bed Pyrolysis Reactor Works

To understand why this method is so effective, it's essential to break down its components and the process flow. The "fluidized bed" itself is the key innovation that sets this technology apart.

The Core Components

- The Reactor Vessel: This is the container where the entire process takes place, designed to withstand high temperatures (typically 400-900°C) and manage the flow of materials.

- Bed Material: A layer of inert particles, most commonly sand, sits at the bottom of the reactor. This material is heated and acts as the primary heat carrier, storing and transferring thermal energy to the feedstock.

- Fluidizing Gas: An inert gas, usually nitrogen, is continuously pumped in from below the bed material. This gas has two critical jobs: it prevents combustion by creating an oxygen-free atmosphere, and its upward flow agitates the sand, causing it to fluidize.

The Process Step-by-Step

- The sand bed is pre-heated to the target pyrolysis temperature.

- The fluidizing gas (nitrogen) is introduced, causing the hot sand particles to lift and mix, behaving like a turbulent, boiling fluid.

- The organic feedstock (e.g., wood chips, shredded plastic) is fed into this intensely hot, moving bed.

- Due to the massive surface area of the sand particles, the feedstock is heated almost instantaneously and uniformly, triggering fast pyrolysis.

- The material rapidly decomposes into a mix of hot vapors (which become bio-oil when cooled), non-condensable gases (syngas), and solid particles (bio-char).

- These products are carried out of the reactor by the gas flow, where they are then separated and collected.

Why Choose a Fluidized Bed? The Key Advantages

The design of a fluidized bed directly translates into several major operational benefits, particularly for applications focused on producing liquid fuels.

Superior Heat Transfer

This is the technology's defining feature. The constant, vigorous mixing of the bed material ensures that the feedstock is heated evenly and incredibly quickly. This avoids hot or cold spots, leading to a consistent and controllable reaction.

Higher Bio-Oil Yield

The rapid heating rates characteristic of a fluidized bed favor the chemical reactions that produce liquid bio-oil. Slower methods tend to "over-cook" the material, leading to a higher proportion of solid char and gas. Fluidized beds maximize the valuable liquid fraction.

Process Flexibility and Scale

Fluidized bed reactors are effective for processing particulate substrates like woody biomass. Furthermore, the technology is scalable and can be built in relatively small, mobile configurations, allowing for decentralized processing of biomass close to its source.

Understanding the Trade-offs

No technology is without its challenges. While powerful, the advantages of a fluidized bed come with specific operational requirements.

Feedstock Preparation

The system works best with feedstock of a consistent and relatively small particle size. Large, bulky, or irregularly shaped materials will not "fluidize" properly and can disrupt the process. This means materials often require pre-processing like grinding or shredding, which adds cost and complexity.

System Complexity

Compared to simpler batch reactors, a fluidized bed system is more mechanically complex. It requires precise control of gas flow rates to maintain fluidization, as well as downstream equipment like cyclones to separate the fine bio-char particles from the hot gas and vapor stream.

Energy Input

Achieving and maintaining the high temperatures of the bed material, along with compressing the large volumes of fluidizing gas, represents a significant energy input. Often, the syngas produced during pyrolysis is burned to provide this energy, making the system more self-sustaining.

Making the Right Choice for Your Goal

The decision to use fluidized bed pyrolysis depends entirely on your feedstock and desired products.

- If your primary focus is maximizing liquid bio-oil yield from particulate biomass: A fluidized bed reactor is the superior choice due to its rapid, uniform heat transfer that defines fast pyrolysis.

- If your primary focus is creating high-quality bio-char with long processing times: A slower pyrolysis technology, which allows the material more residence time in the reactor, would be more appropriate.

- If your primary focus is simplicity and processing large, unprepared waste: A different reactor design, like a rotary kiln, might be more tolerant of varied feedstock, though likely at the cost of bio-oil yield.

By understanding that the fluidized bed is a tool for controlling heat transfer, you can effectively match the technology to your specific conversion goals.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Superior Heat Transfer | Ensures rapid, uniform heating for high bio-oil yield |

| Fast Pyrolysis Process | Maximizes liquid fuel production from organic waste |

| Scalable Reactor Design | Suitable for decentralized, mobile processing units |

| Consistent Product Quality | Avoids hot/cold spots for reliable output |

| Requires Prepared Feedstock | Best for small, uniform particles like wood chips |

Ready to optimize your pyrolysis process?

At KINTEK, we specialize in providing high-performance lab equipment and consumables tailored for advanced thermal conversion research. Whether you're developing next-generation biofuels or optimizing waste-to-energy systems, our reactors and analytical tools are designed to deliver precise, reliable results.

We help you:

- Achieve superior heat transfer and maximize bio-oil yields

- Scale your pyrolysis technology from lab to pilot plant

- Access expert support for complex feedstock challenges

Let's discuss how KINTEK's solutions can accelerate your renewable energy projects. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs