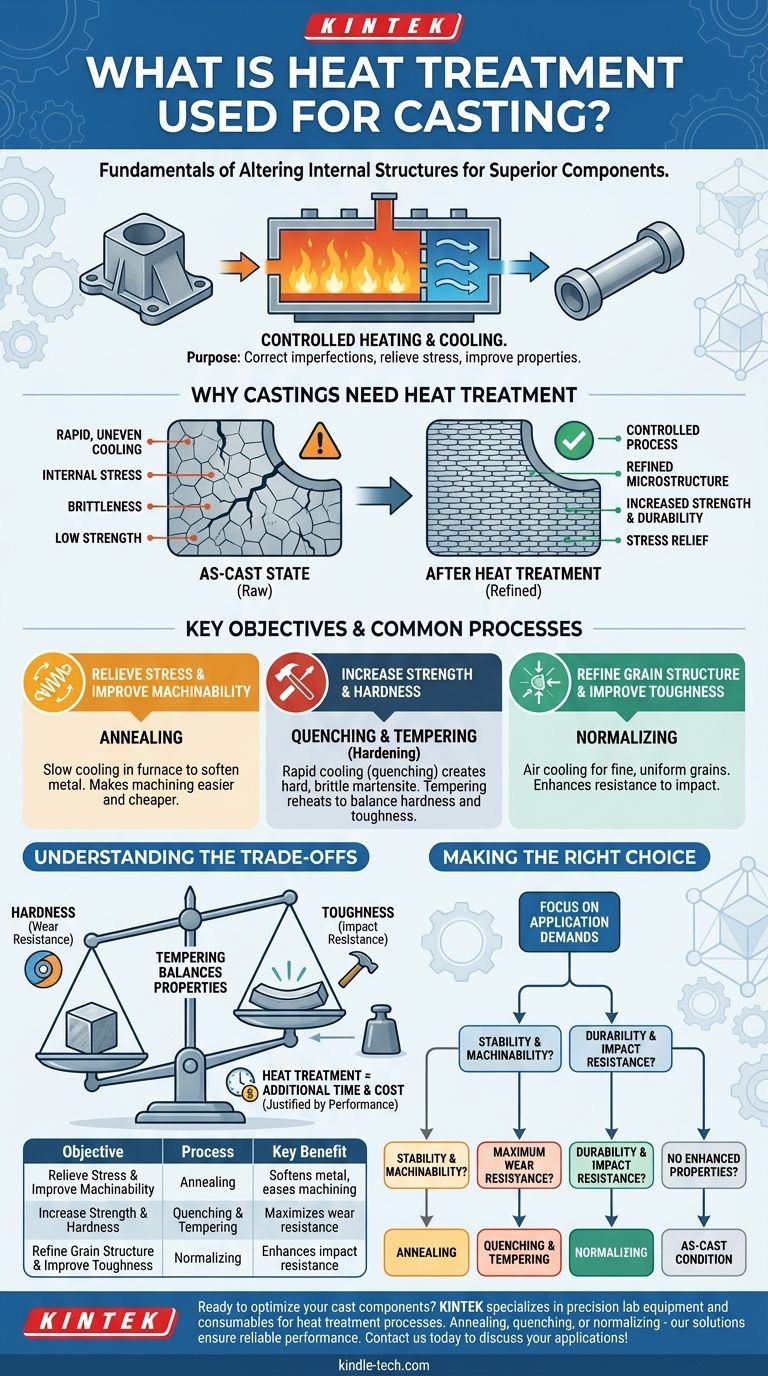

In essence, heat treatment for casting is a controlled heating and cooling process used after a metal part has been cast to fundamentally alter its internal structure. This is done to improve its mechanical properties, making the final component stronger, more durable, and better suited for its intended application than it would be in its raw, "as-cast" state.

The core purpose of heat treating a casting is to correct the structural imperfections and relieve the internal stresses created during the solidification process. It transforms a potentially brittle and inconsistent raw part into a reliable, high-performance engineering component.

Why Castings Require Heat Treatment

A metal part fresh from its mold is in an "as-cast" condition. While it has the correct shape, its internal microscopic structure, or microstructure, is often far from optimal due to the uncontrolled nature of cooling.

The Problem with the "As-Cast" State

The rapid and uneven cooling of molten metal in a mold creates significant internal stresses. This can make the part prone to cracking or warping later in its service life.

Furthermore, the cooling process can result in a coarse and non-uniform grain structure. This often leads to undesirable properties like brittleness and low strength.

The Goal: Refining the Microstructure

Heat treatment acts as a corrective measure. By carefully raising the casting to a specific temperature, holding it there, and then cooling it at a controlled rate, we can refine this internal structure.

This process allows the metal's crystalline structure to realign into a more uniform and favorable arrangement, directly enhancing its mechanical properties.

Key Objectives and Common Processes

Different heat treatment processes are used to achieve specific engineering goals. The choice depends entirely on what you need the final component to do.

Objective 1: Relieve Stress and Improve Machinability

Process: Annealing. This involves heating the casting to a high temperature and then cooling it very slowly, often by leaving it in the furnace to cool. This slow cooling relieves the internal stresses locked in from the casting process.

A major benefit of annealing is that it softens the metal, making it significantly easier and less costly to machine.

Objective 2: Increase Strength and Hardness

Process: Quenching and Tempering (Hardening). To make a steel or iron casting much harder and stronger, it is heated to a high temperature and then cooled very rapidly by "quenching" it in a liquid like water, oil, or polymer.

This rapid cooling traps the microstructure in a very hard but also very brittle state called martensite. The part is then tempered—reheated to a lower temperature—to reduce that brittleness and increase its toughness, arriving at a functional balance of properties.

Objective 3: Refine Grain Structure and Improve Toughness

Process: Normalizing. This process is common for steel castings. It involves heating the part above its critical temperature and then letting it cool in open air.

This air cooling is faster than annealing but slower than quenching. It results in a fine, uniform grain structure that increases both the strength and toughness of the casting, making it more resistant to impact.

Understanding the Trade-offs

Heat treatment is not a magic bullet; it is a series of engineering compromises designed to achieve a specific performance profile. Understanding these trade-offs is critical.

The Hardness vs. Toughness Dilemma

The most fundamental trade-off is between hardness and toughness. A very hard material excels at resisting wear and abrasion, but it is often brittle and can fracture easily under sudden impact.

Conversely, a very tough material can absorb a lot of energy and deform without breaking, but it may be too soft to resist surface wear. The tempering process is specifically designed to navigate this trade-off by sacrificing some hardness to gain essential toughness.

The Impact on Cost and Time

Heat treatment is an additional manufacturing step that adds both time and cost to the production cycle. Furnaces consume significant energy, and the process extends the lead time for finished parts.

Therefore, the decision to heat treat must be justified by the performance requirements of the final application. It is specified only when the properties of the as-cast material are insufficient.

Making the Right Choice for Your Goal

Selecting the correct heat treatment process is driven by the demands of the component's service environment.

- If your primary focus is stability and machinability: Annealing is the best choice to relieve internal stress and soften the material for easier manufacturing.

- If your primary focus is maximum wear resistance: A quench and temper process is necessary to achieve the high hardness required to prevent abrasion.

- If your primary focus is durability and impact resistance: Normalizing is an excellent and cost-effective method for refining the grain structure to improve the overall toughness of steel castings.

- If your component requires no enhanced properties: For non-critical applications, leaving the part in its as-cast condition may be the most economical solution.

Ultimately, heat treatment elevates a simple casting from a shaped object to a precisely engineered component with tailored properties.

Summary Table:

| Objective | Process | Key Benefit |

|---|---|---|

| Relieve Stress & Improve Machinability | Annealing | Softens metal, eases machining |

| Increase Strength & Hardness | Quenching & Tempering | Maximizes wear resistance |

| Refine Grain Structure & Improve Toughness | Normalizing | Enhances impact resistance |

Ready to optimize your cast components? KINTEK specializes in precision lab equipment and consumables for heat treatment processes. Whether you're annealing, quenching, or normalizing, our solutions ensure reliable performance and consistent results for your laboratory needs. Contact us today to discuss how we can support your heat treatment applications!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- What is a furnace classified as? Understand the Two Main Types for Your Application

- At what temperature does quartz soften? Understand the practical limits for lab equipment

- What is the difference between a lab furnace and a lab oven? Choose the Right Heating Tool for Your Lab

- What is a muffle furnace used for in microbiology? Essential for Depyrogenation and Ashing

- What is SV and PV in a muffle furnace? Master Temperature Control for Precision Results