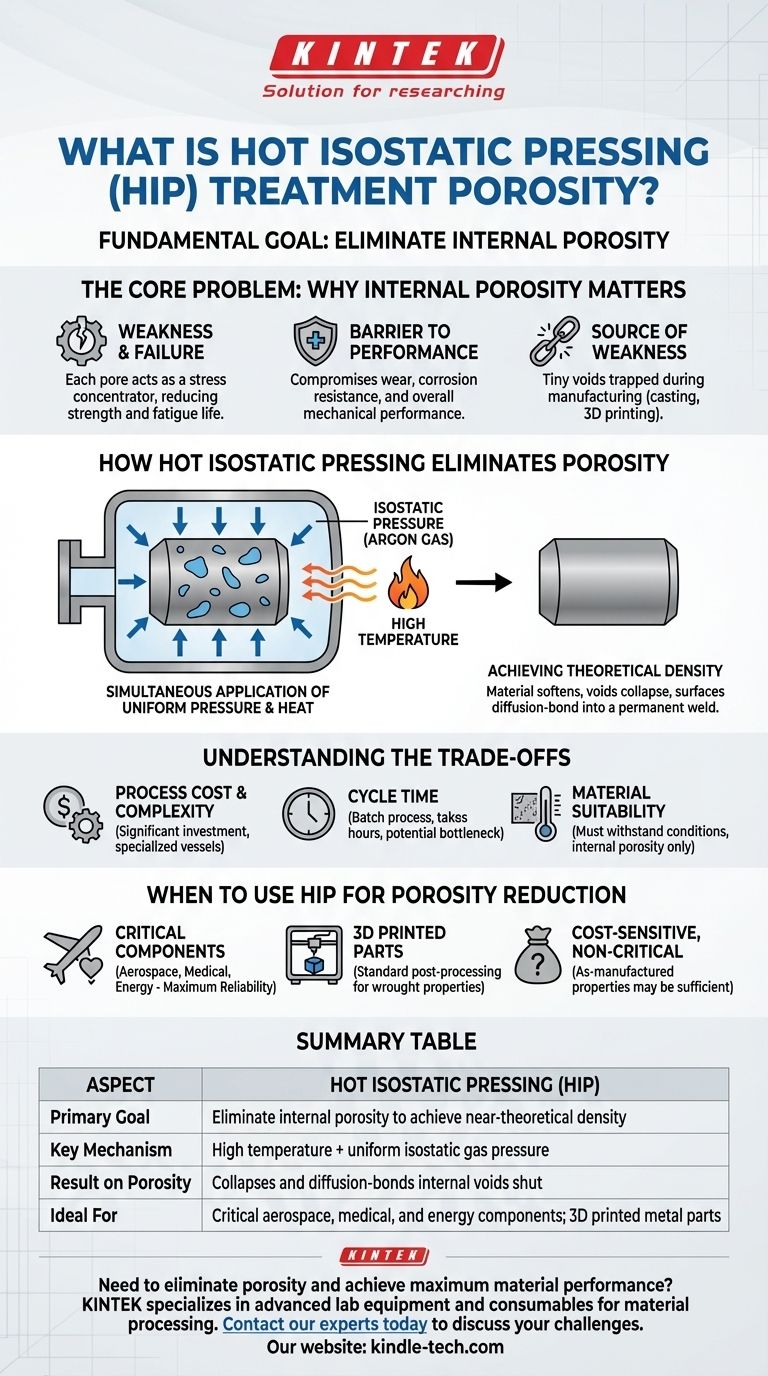

At its core, Hot Isostatic Pressing (HIP) is a treatment designed to fundamentally eliminate internal porosity in a material. It uses a combination of high temperature and uniform, high-pressure gas to physically collapse and weld shut microscopic voids, pores, and defects that are trapped within a component after manufacturing.

The central purpose of using Hot Isostatic Pressing in relation to porosity is not merely to reduce it, but to achieve a fully dense material. This process transforms a component with internal weak points into a solid, homogenous structure with vastly superior mechanical properties.

The Core Problem: Why Internal Porosity Matters

The Source of Weakness

Porosity refers to the tiny, empty spaces or voids trapped within a material. These are often an unavoidable byproduct of manufacturing processes like casting or additive manufacturing (3D printing).

The Point of Failure

Each internal pore acts as a stress concentrator. Under load, these voids become the initiation points for cracks, significantly reducing the material's strength, ductility, and especially its fatigue life.

The Barrier to Performance

A porous material is, by definition, not fully dense. This inherent lack of density compromises its wear resistance, corrosion resistance, and overall mechanical performance, making it unreliable for critical applications.

How Hot Isostatic Pressing Eliminates Porosity

The Key Ingredients: Temperature and Pressure

The HIP process places a component inside a sealed, high-pressure vessel. The temperature is raised to a point where the material becomes soft and plastic, but does not melt.

Simultaneously, the vessel is filled with a high-pressure inert gas, typically argon. This is where the term "isostatic" becomes critical.

The Power of Uniform Pressure

The inert gas applies immense, uniform pressure on the component from all directions. Because the pressure is equal everywhere on the surface, the part does not distort or change its shape.

Instead, this external pressure is transferred through the solid material and acts on the internal voids. The soft, heated material collapses inward under this force, physically closing the pores.

The Result: Achieving Theoretical Density

At the high temperatures of the process, the surfaces of the collapsed voids diffusion-bond together, creating a permanent, metallurgical weld. This effectively removes the internal defects.

The final result is a component with a density that is close to 100% of its theoretical density, meaning it is a solid, void-free material.

Understanding the Trade-offs

Process Cost and Complexity

HIP requires specialized, high-pressure containment vessels, which represent a significant capital investment. The process itself adds a notable cost to the manufacturing of each component.

Cycle Time

HIP is a batch process that can take several hours to complete. This can be a bottleneck in high-volume production environments compared to continuous manufacturing methods.

Material Suitability

The process is only suitable for materials that can withstand the high temperatures and pressures without degrading. Additionally, it can only eliminate internal porosity; it cannot fix surface-connected defects unless the part is first encapsulated.

When to Use HIP for Porosity Reduction

For any component, the decision to use HIP is a balance between performance requirements and cost.

- If your primary focus is maximum reliability and fatigue life: HIP is the definitive choice for critical components in aerospace, medical, or energy applications where failure is not an option.

- If your primary focus is improving the properties of 3D printed metal parts: HIP is a standard post-processing step to remove the inherent porosity from additive manufacturing and achieve the performance of a wrought material.

- If your primary focus is cost-sensitive, non-critical applications: The significant benefits of HIP may not justify the added expense, and the as-manufactured material properties may be sufficient.

Ultimately, understanding HIP empowers you to make an informed decision on when to invest in creating a truly solid and reliable material.

Summary Table:

| Aspect | Hot Isostatic Pressing (HIP) |

|---|---|

| Primary Goal | Eliminate internal porosity to achieve near-theoretical density |

| Key Mechanism | High temperature + uniform isostatic gas pressure |

| Result on Porosity | Collapses and diffusion-bonds internal voids shut |

| Ideal For | Critical aerospace, medical, and energy components; 3D printed metal parts |

Need to eliminate porosity and achieve maximum material performance?

KINTEK specializes in advanced lab equipment and consumables for material processing. Our solutions support the development and quality control of materials treated with processes like Hot Isostatic Pressing. If you are working on critical components that demand 100% density and superior mechanical properties, our expertise can help.

Contact our experts today to discuss how we can support your laboratory's material science and manufacturing challenges.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- What is HIP in material processing? Achieve Near-Perfect Density for Critical Components