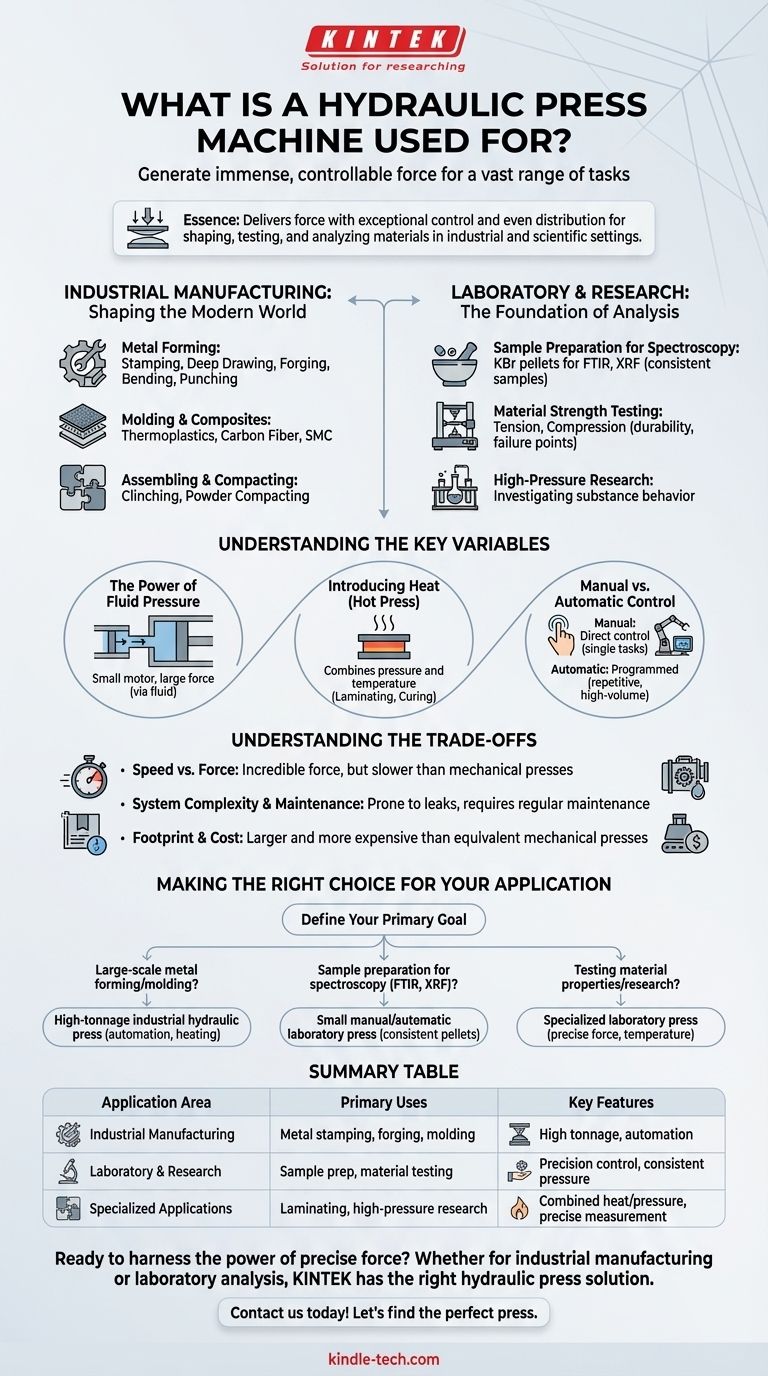

In essence, a hydraulic press is a machine used to generate immense, controllable force for a vast range of tasks. Its applications fall into two primary categories: heavy-duty industrial manufacturing—such as forming metal, molding composites, and assembling parts—and precise laboratory work, where it is essential for preparing samples for analysis and testing material properties.

The true value of a hydraulic press isn't just its raw power. It's the ability to deliver that force with exceptional control and even distribution, making it an indispensable tool for shaping, testing, and analyzing materials in both industrial and scientific settings.

The Two Worlds of a Hydraulic Press

While all hydraulic presses operate on the same principle of fluid pressure, their applications are distinctly split between the factory floor and the research laboratory.

Industrial Applications: Shaping the Modern World

In manufacturing, hydraulic presses are the workhorses for manipulating materials that require enormous force.

- Metal Forming: This is a classic application. Presses are used for stamping car body panels, deep drawing to create items like kitchen sinks, forging raw metal into strong components, and bending or punching sheet metal.

- Molding and Composites: Many modern materials are formed in hydraulic presses. This includes compressing thermoplastics, forming carbon fiber components for aerospace, and molding sheet molded composites (SMC) for automotive parts.

- Assembling and Compacting: Presses are also used for clinching (joining sheet metal without fasteners), compacting powders into solid forms, and other assembly operations that require significant, even pressure.

Laboratory Applications: The Foundation of Analysis

In a scientific context, the press's value shifts from raw production to precision and preparation.

- Sample Preparation for Spectroscopy: This is a critical laboratory function. A press is used to compress powdered material into a thin, homogenous pellet. This is essential for techniques like FTIR spectroscopy (using KBr pellets) and XRF analysis, as it creates a consistent sample for the instrument to analyze.

- Material Strength Testing: Laboratory presses are used to test the physical limits of a material. They can perform tension tests by pulling samples apart or compression tests to determine durability and failure points.

- High-Pressure Research: Scientists use hydraulic presses to investigate how different substances behave under extreme pressure, contributing to fields from geology to materials science.

Understanding the Key Variables

The versatility of the hydraulic press comes from its ability to manipulate a few key variables with high precision.

The Power of Fluid Pressure

The machine works by using a small piston to apply pressure to an incompressible fluid (like oil). This pressure is transferred through the fluid to a much larger piston, multiplying the initial force exponentially. This is what allows a relatively small motor to generate many tons of force.

Introducing Heat: The Hydraulic Hot Press

Many applications benefit from combining pressure with temperature. Hydraulic hot presses have integrated heating elements. This allows for processes like laminating, curing advanced composites, or melting polymers into thin films, where both force and heat are required simultaneously.

Manual vs. Automatic Control

- Manual presses are common in laboratories for single, specific tasks like making one sample pellet. They offer direct, hands-on control.

- Automatic presses are programmed for repetitive tasks. They are essential for industrial production lines and high-throughput labs where consistency and efficiency are paramount.

Understanding the Trade-offs

While powerful, hydraulic presses are not the solution for every problem. Understanding their limitations is key to using them effectively.

Speed vs. Force

The primary trade-off for a hydraulic press is speed. They can generate incredible force, but they are generally slower than mechanical presses. For high-speed, high-volume operations like simple stamping, a mechanical press may be more suitable.

System Complexity and Maintenance

Hydraulic systems rely on pumps, valves, seals, and hydraulic fluid. This complexity means they can be prone to fluid leaks and require regular maintenance to ensure reliable operation.

Footprint and Cost

The components required to generate and contain high hydraulic pressure—the heavy frame, pump, and cylinder—often result in a larger and more expensive machine compared to a mechanical press of equivalent tonnage.

Making the Right Choice for Your Application

To select the correct type of press, you must first define your primary goal.

- If your primary focus is large-scale metal forming or molding: You need a high-tonnage industrial hydraulic press, likely with automation and heating capabilities for production efficiency.

- If your primary focus is preparing samples for spectroscopic analysis (FTIR, XRF): A smaller manual or automatic laboratory press is the ideal tool for creating consistent, high-quality sample pellets.

- If your primary focus is testing material properties or high-pressure research: A specialized laboratory press with precise force, temperature, and displacement measurement is necessary.

Understanding these core functions and trade-offs empowers you to select the right hydraulic press to apply precise force exactly where you need it.

Summary Table:

| Application Area | Primary Uses | Key Features |

|---|---|---|

| Industrial Manufacturing | Metal stamping, forging, composite molding, assembly | High tonnage, automation, heating capabilities |

| Laboratory & Research | Sample preparation (KBr pellets), material testing, spectroscopy | Precision control, manual/auto operation, consistent pressure |

| Specialized Applications | Laminating, powder compacting, high-pressure research | Combined heat and pressure, precise force measurement |

Ready to harness the power of precision force for your applications?

Whether you're in industrial manufacturing requiring high-tonnage forming or a laboratory needing reliable sample preparation for FTIR/XRF analysis, KINTEK has the right hydraulic press solution for you. Our expertise in lab equipment ensures you get the perfect balance of force, control, and reliability for your specific needs.

Contact us today to discuss how our hydraulic presses can enhance your production quality or analytical accuracy. Let's find the perfect press for your requirements. Get in touch with our experts now!

Visual Guide

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How do laboratory hydraulic presses facilitate biomass pelletization? Optimize Biofuel Density and Prevent Slagging

- What role does a laboratory hydraulic press play in preparing solid model materials? Standardize for Precise Data.

- What is the function of a laboratory hydraulic press for Li10GeP2S12 pellets? Optimize Solid-State Battery Performance

- Why is a hydraulic pellet press used for FTIR? Transform Nanofillers into Clear Data

- How does a laboratory manual hydraulic press facilitate the FT-IR characterization of catalysts? Master Sample Prep.