In modern metallurgy, a hydrogen bell type annealing furnace is a specialized piece of equipment designed for high-volume heat treatment. It combines a mobile, bell-shaped heating chamber with a controlled hydrogen atmosphere to anneal materials, primarily metal coils, without surface oxidation, resulting in a "bright" finish.

The core principle of a hydrogen bell furnace is decoupling the heating unit (the "bell") from the material base. This allows for an efficient, cyclical process where the hydrogen atmosphere protects the material's surface integrity while the mobile bell maximizes heating element uptime.

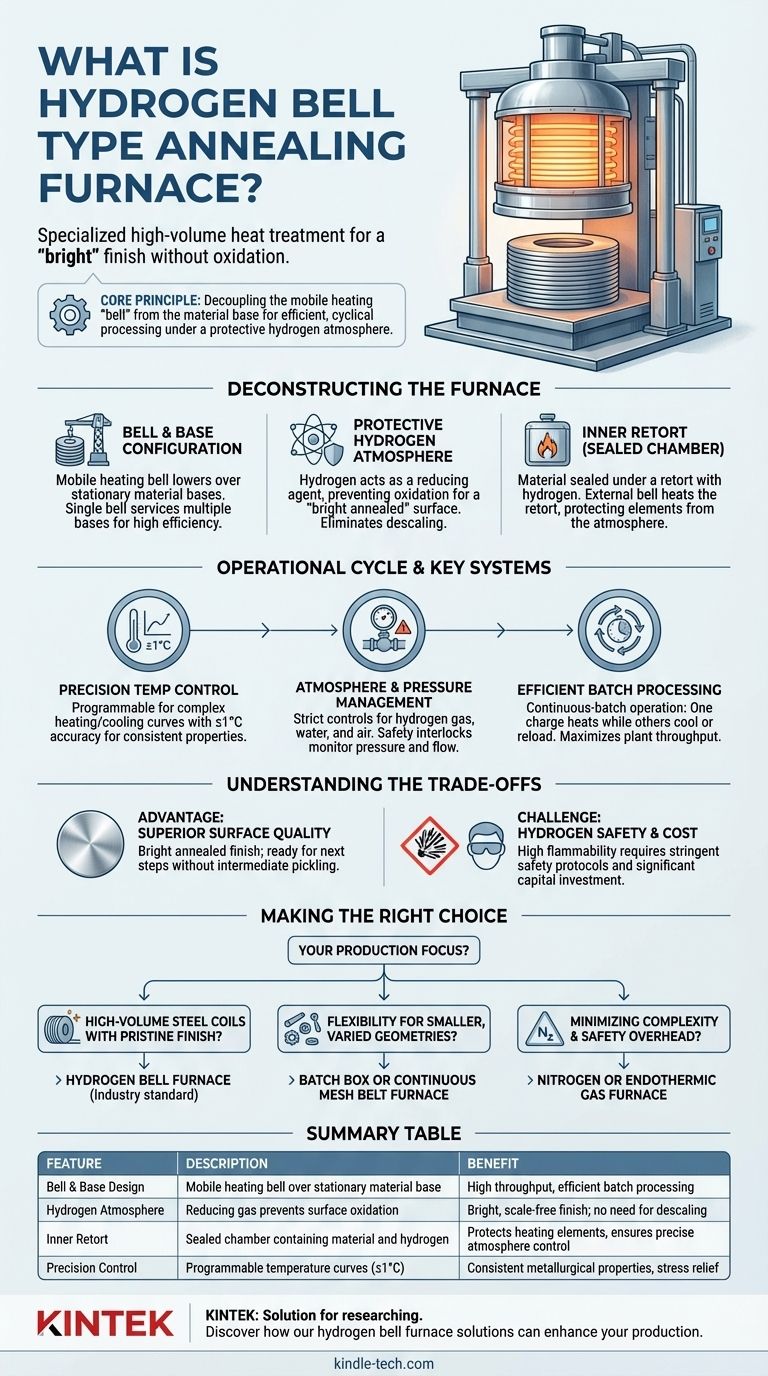

Deconstructing the Hydrogen Bell Furnace

To understand this system, it's best to break it down into its three defining characteristics: the mechanical design, the protective atmosphere, and the control systems.

The Bell and Base Configuration

A bell furnace is a two-part system. The material to be annealed, such as steel coils, is stacked on a stationary base.

A separate, movable bell, which contains the heating elements, is then lowered over the material by a crane or hydraulic lift system. This design means a single heating bell can service multiple bases, creating a highly efficient workflow.

The Protective Hydrogen Atmosphere

The primary purpose of the hydrogen is to create a protective, or reducing, atmosphere. When heated, metals like steel react readily with oxygen, forming an oxide layer (scale) on the surface.

Hydrogen actively prevents this. As a powerful reducing agent, it bonds with any residual oxygen in the furnace chamber, preventing it from reacting with the metal. This process, known as bright annealing, results in a clean, bright, and scale-free surface that often requires no further cleaning or pickling.

The Inner Retort (Sealed Chamber)

The material on the base is first covered by a thin, sealed inner cover, often called a retort. This retort contains the material and the controlled hydrogen atmosphere.

The larger heating bell is then lowered over this entire assembly. The heating elements in the bell heat the retort from the outside, which in turn heats the material inside via radiation and convection. This ensures the expensive heating elements are never directly exposed to the process atmosphere.

Operational Cycle and Key Systems

The value of a bell furnace lies in its operational efficiency and the precision of its output. This is governed by its integrated control and processing systems.

Precision Temperature Control

These furnaces utilize advanced, programmable temperature controllers that can execute complex heating and cooling curves with high precision, often to within ±1°C.

This level of control is critical for achieving specific metallurgical properties, ensuring consistency across large batches and relieving internal stresses without damaging the material.

Atmosphere and Pressure Management

The furnace system includes precise controls for managing the water, air, and, most importantly, the hydrogen gas. Pressure control systems ensure the integrity of the atmosphere inside the retort is maintained.

Safety interlocks and alarm systems are essential for monitoring gas pressure and flow, as hydrogen is highly flammable.

Efficient Batch Processing

The bell-and-base configuration enables a highly efficient continuous-batch operation. While one charge is being heated under the bell, a second charge on another base can be cooling, and a third base can be unloaded and reloaded.

This minimizes downtime for the most expensive part of the system—the heating bell—and maximizes overall plant throughput.

Understanding the Trade-offs

While powerful, a hydrogen bell furnace is a specialized solution with clear advantages and challenges.

Advantage: Superior Surface Quality

The primary benefit is the bright annealed finish. By preventing oxidation, these furnaces produce a product with a high-quality surface that is ready for subsequent processing, like coating or cold rolling, without an intermediate descaling step.

Challenge: Hydrogen Safety and Handling

Hydrogen is extremely flammable and can be explosive under certain conditions. Operating a hydrogen furnace requires stringent safety protocols, sophisticated leak detection systems, and robust purging procedures using an inert gas like nitrogen before and after each cycle.

Cost: High Initial Investment

The complexity of the furnace, its control systems, and the required safety infrastructure result in a significant capital investment. However, for high-volume producers, this cost is often justified by the high throughput, labor efficiency, and superior product quality.

Making the Right Choice for Your Application

Selecting the right annealing technology depends entirely on your production goals, material requirements, and operational capabilities.

- If your primary focus is high-volume production of steel coils or wire with a pristine surface finish: A hydrogen bell furnace is an industry-standard solution perfectly suited for this goal.

- If your primary focus is process flexibility for smaller, varied part geometries: A different furnace type, such as a smaller batch box furnace or a continuous mesh belt furnace, may be more cost-effective.

- If your primary focus is minimizing infrastructure complexity and safety overhead: Consider a furnace using a 100% nitrogen or a generated endothermic gas atmosphere, which has fewer handling risks than high-concentration hydrogen.

Ultimately, choosing a hydrogen bell furnace is a strategic decision that balances the pursuit of exceptional surface quality and high throughput against the demands of a complex and safety-critical operation.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Bell & Base Design | Mobile heating bell over stationary material base | High throughput, efficient batch processing |

| Hydrogen Atmosphere | Reducing gas prevents surface oxidation | Bright, scale-free finish; no need for descaling |

| Inner Retort | Sealed chamber containing material and hydrogen | Protects heating elements, ensures precise atmosphere control |

| Precision Control | Programmable temperature curves (±1°C) | Consistent metallurgical properties, stress relief |

Ready to achieve superior surface quality and high throughput in your annealing process? KINTEK specializes in advanced lab equipment and consumables, providing reliable solutions for your laboratory's thermal processing needs. Our expertise in furnace technology can help you implement efficient, safe, and precise annealing operations. Contact us today to learn how our hydrogen bell furnace solutions can enhance your production and deliver exceptional results for your metal coils.

Visual Guide

Related Products

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- Why is an industrial furnace with hydrogen atmosphere control necessary for the pre-sintering of Fe-Cr-Al materials?

- What is the inert air technique? Protect Your Sensitive Materials from Oxygen and Moisture

- How are tube atmosphere furnaces and water vapor generators used together to evaluate the performance of Cr-Si coatings?

- What are hydrogen furnaces used for? Achieve Purity and Speed in High-Temperature Processing

- What are the benefits of using an atmosphere-controlled furnace for 316LN annealing? Preserve Strength and Surface.

- What are the characteristics and uses of a prepared nitrogen-based atmosphere? Master Heat Treatment Precision

- What is controlled atmosphere heat treatment? Achieve Superior Metal Performance and Consistency

- Why is high-purity argon protection essential for titanium dioxide reduction? Ensure Peak Metal Purity