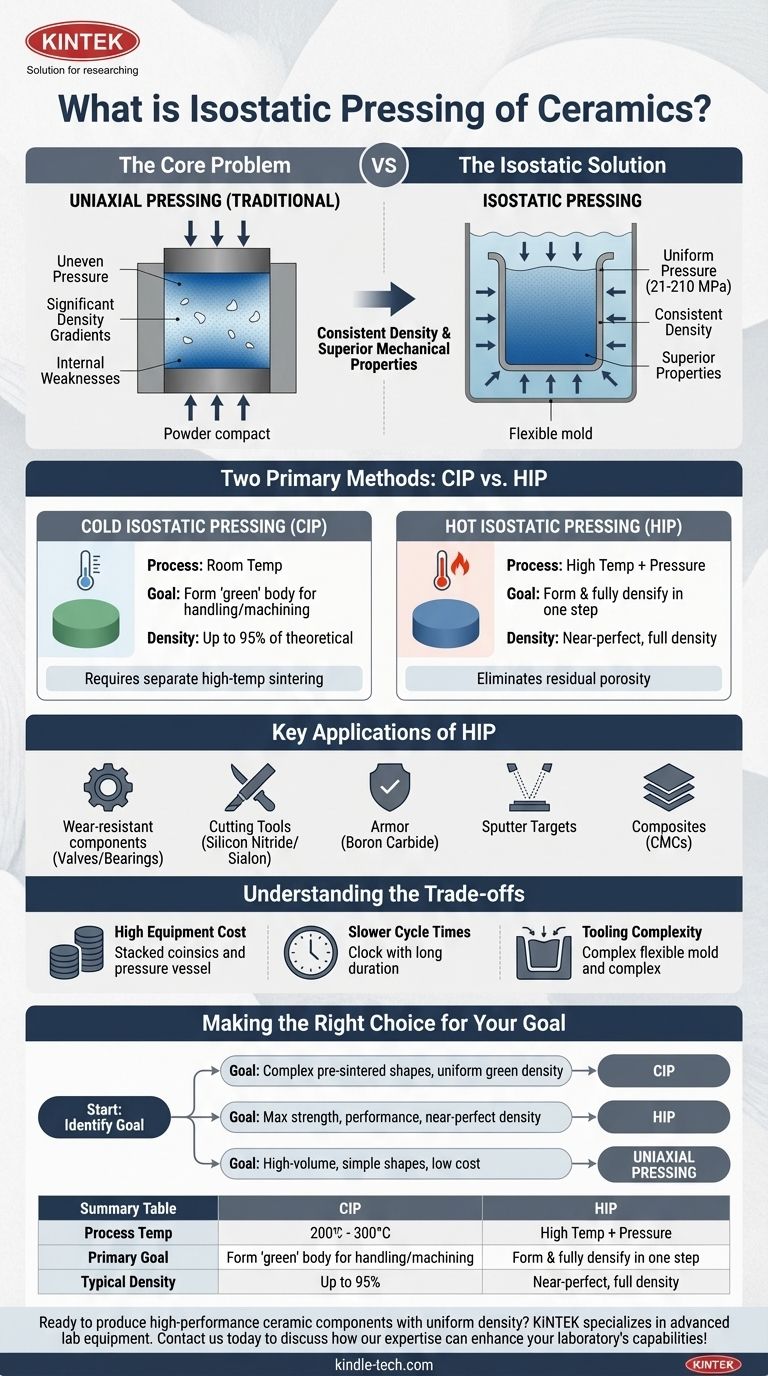

Isostatic pressing is a powder metallurgy process used to form ceramic components by subjecting a powder compact to uniform, high pressure from all directions. Unlike traditional uniaxial pressing, which applies force from only one or two directions, isostatic pressing uses a fluid or gas as the pressure-transmitting medium, ensuring consistent density throughout the part.

The central purpose of isostatic pressing is to overcome the density variations and internal stresses common in conventionally pressed parts. By applying pressure uniformly, it produces highly consistent ceramic components with superior mechanical properties, enabling the creation of complex shapes that are otherwise difficult to manufacture.

Why Use Isostatic Pressing?

The Core Problem: Voids and Non-Uniform Density

When ceramic powder is pressed in a rigid die (uniaxial pressing), friction between the powder and the die walls prevents pressure from being transmitted evenly.

This results in a component with significant density gradients. The areas closest to the punch are dense, while the center and areas far from the punch are less dense, creating internal weaknesses.

The Isostatic Solution: Uniform Pressure

Isostatic pressing immerses the powder, which is sealed in a flexible mold, into a high-pressure fluid or gas.

This pressure, ranging from 21 to 210 MPa (3,000 to 30,000 psi), acts equally on all surfaces of the mold. This eliminates the effect of die-wall friction, resulting in a highly uniform density throughout the component, known as a "green" body.

The Two Primary Methods: CIP vs. HIP

The choice between isostatic methods depends on whether the goal is simply to form the part before heating or to form and fully densify it in a single step.

Cold Isostatic Pressing (CIP)

CIP is performed at or near room temperature. The primary goal is to compact the ceramic powder into a solid green body with enough strength for handling and machining.

This process can achieve up to 95% of the ceramic's theoretical density in the green state. The part must then undergo a separate high-temperature sintering process to achieve its final, full density and strength.

Hot Isostatic Pressing (HIP)

HIP combines immense pressure with high temperature in a single process. It is used to simultaneously compact and sinter the powder, consolidating it into a fully dense component.

Because it eliminates residual porosity, HIP is used to create ultra-high-performance ceramics with superior mechanical properties for the most demanding environments.

Key Applications of HIP

The exceptional density and uniformity achieved by HIP make it essential for advanced technical ceramics.

Applications include producing wear-resistant components for heavy-duty valves and bearings, silicon nitride and sialon cutting tools, and robust boron carbide (B4C) for armor. It is also used for sputter targets and composite materials like CMCs (Ceramic Matrix Composites).

Understanding the Trade-offs

High Equipment Cost

Both CIP and especially HIP require specialized high-pressure vessels and control systems. The capital investment for this equipment is significantly higher than for conventional presses.

Slower Cycle Times

Isostatic pressing is a batch process. The time required to load the mold, pressurize the vessel, hold at pressure, and de-pressurize is much longer than the seconds-long cycle of a mechanical press, making it less suitable for high-volume, low-cost parts.

Tooling Complexity

While excellent for complex external shapes, the flexible molds can be expensive to design and produce. Creating precise internal features or sharp corners can be challenging and may require more sophisticated tooling approaches.

Making the Right Choice for Your Goal

To select the appropriate method, you must align the process capabilities with your component's performance requirements and cost targets.

- If your primary focus is creating complex pre-sintered shapes with uniform green density: Cold Isostatic Pressing (CIP) is the ideal choice, followed by a conventional sintering cycle.

- If your primary focus is achieving maximum strength, performance, and near-perfect density: Hot Isostatic Pressing (HIP) is necessary, especially for advanced technical ceramics and composites.

- If your primary focus is high-volume production of simple shapes where cost is paramount: Traditional uniaxial pressing is likely the more economical and faster solution.

Ultimately, isostatic pressing unlocks a level of material performance and geometric complexity that conventional methods simply cannot reach.

Summary Table:

| Method | Process Temperature | Primary Goal | Typical Density Achieved |

|---|---|---|---|

| Cold Isostatic Pressing (CIP) | Room Temperature | Form a 'green' body for handling and sintering | Up to 95% of theoretical density |

| Hot Isostatic Pressing (HIP) | High Temperature | Fully densify and sinter in one step | Near-perfect, full density |

Ready to produce high-performance ceramic components with uniform density?

KINTEK specializes in advanced lab equipment and consumables for ceramic processing. Whether you're exploring Cold Isostatic Pressing (CIP) for complex shapes or Hot Isostatic Pressing (HIP) for maximum strength, our solutions help you achieve superior results. Contact us today to discuss how our expertise can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does isostatic pressing equipment enhance lithium metal anode contact? Optimize Your Solid-State Battery Assembly

- Why is a Cold Isostatic Press (CIP) Preferred for Sulfide Solid Electrolytes? Maximize Your Ionic Conductivity

- What is the process of isostatic press? Achieve Uniform Density and Complex Shapes

- How does Cold Isostatic Pressing (CIP) benefit SiC ceramic reactors? Achieve Flawless Material Integrity

- What are the advantages of isostatic pressing? Achieve Superior Material Integrity and Design Freedom

- What are the different types of cold isostatic pressing? Wet-Bag vs. Dry-Bag for Your Production Needs

- Why is semi-isostatic pressing used for ceramics? Unlock Uniform Density and Superior Precision

- What advantages does Cold Isostatic Pressing (CIP) offer for nickel-alumina composites? Enhance Density & Strength