At its core, the KBr method is a sample preparation technique used in infrared (IR) spectroscopy to analyze solid materials. It involves finely grinding a small amount of a solid sample with pure potassium bromide (KBr) powder and then compressing the mixture under high pressure to form a small, transparent disc, or "pellet." Because KBr is transparent to infrared light, the IR beam can pass through the pellet, allowing the spectrometer to measure the absorbance of the embedded sample.

The KBr pellet method is a foundational technique that solves a fundamental problem: how to make an opaque solid sample transparent enough for analysis. It works by dispersing the sample in a salt matrix (KBr) that becomes a clear window for infrared radiation when compressed, revealing the sample's unique molecular fingerprint.

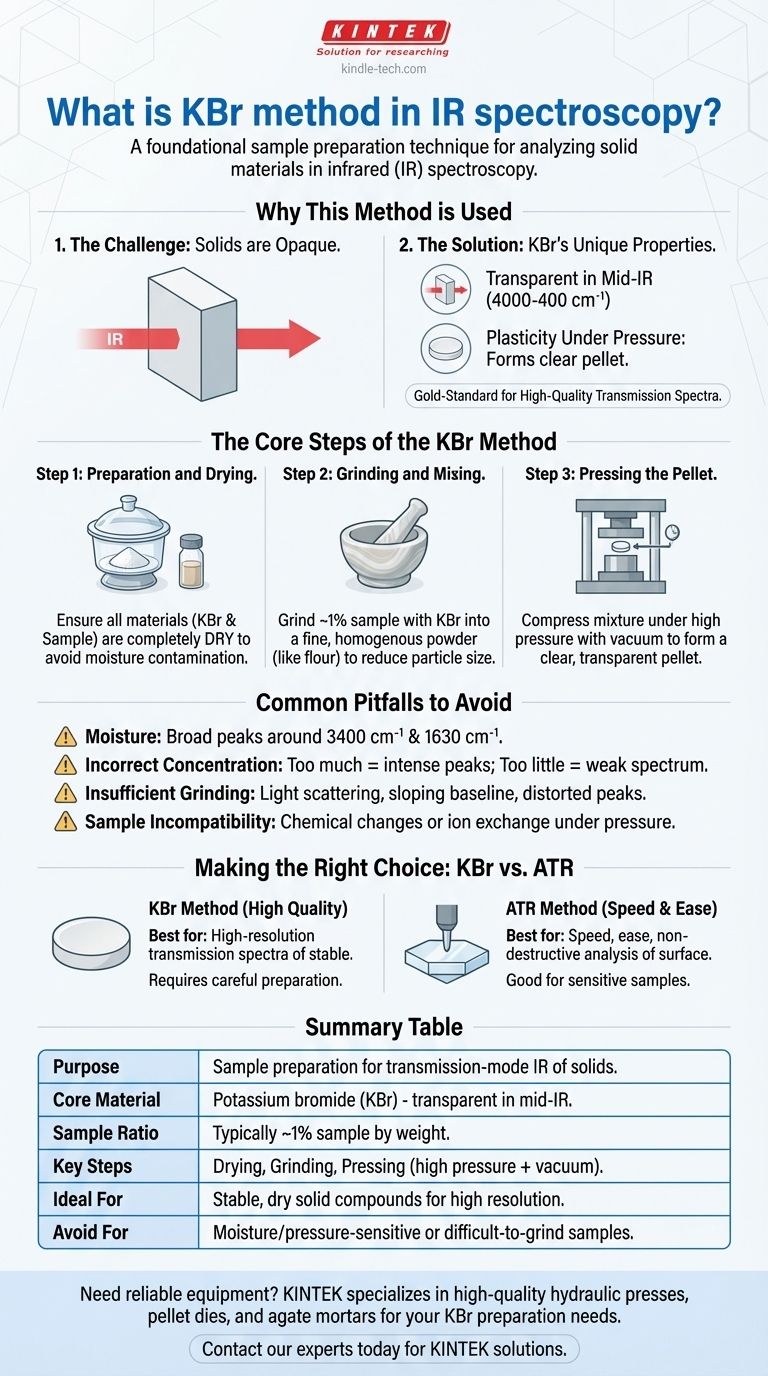

Why This Method is Used

The Challenge of Analyzing Solids

Most IR spectrometers are designed to work in transmission mode, meaning an infrared beam must pass directly through the sample to be detected. While this is straightforward for liquids and gases, most solid materials are opaque and will block the beam entirely. The KBr method transforms a solid into a medium that is transparent in the infrared region.

The Unique Properties of KBr

Potassium bromide (KBr) is the material of choice for two critical reasons. First, it is transparent across the entire mid-infrared range (4000-400 cm⁻¹), meaning it does not have its own absorption peaks that would interfere with the sample's spectrum. Second, alkali halides like KBr exhibit plasticity under pressure, flowing to form a solid, glass-like disc that holds the sample in place.

Achieving High-Quality Spectra

When prepared correctly, the KBr pellet method can produce a high-resolution spectrum with sharp, well-defined peaks and a flat baseline. For many applications, it is considered a gold-standard technique for obtaining a clean transmission spectrum of a solid compound.

The Core Steps of the KBr Method

1. Preparation and Drying

The most critical first step is ensuring all materials are completely dry. KBr is hygroscopic, meaning it readily absorbs moisture from the air. Any water present will create a large, broad absorption band in the spectrum, potentially obscuring important sample peaks. Both the KBr powder and the sample should be dried in an oven before use.

2. Grinding and Mixing

A very small amount of sample (typically ~1% by weight) is added to the KBr powder. The mixture is then ground together, usually with an agate mortar and pestle, until it becomes a fine, homogenous powder with a consistency like flour. Thorough grinding is essential to reduce the particle size of the sample and ensure it is evenly dispersed.

3. Pressing the Pellet

The powder mixture is placed into a pellet die, which is then set in a hydraulic press. The die is compressed under several tons of pressure. A vacuum is often applied during this process to remove trapped air and any residual moisture, which helps create a perfectly clear, non-fractured pellet.

Common Pitfalls to Avoid

The Problem of Moisture

As mentioned, water contamination is the most common issue. The presence of a broad absorption band around 3400 cm⁻¹ (O-H stretch) and a sharper one near 1630 cm⁻¹ is a classic sign that the KBr or sample was not sufficiently dry.

Incorrect Sample Concentration

Using too much sample will result in absorption peaks that are too intense ("bottoming out"), making quantitative analysis impossible. Conversely, too little sample will produce a weak spectrum where the peaks are difficult to distinguish from baseline noise.

Insufficient Grinding

If the sample's particle size is too large, it can cause light scattering within the pellet. This effect, known as the Christiansen effect, results in a sloping baseline and distorted, asymmetric peak shapes, making the spectrum difficult to interpret accurately.

Sample Incompatibility

Under the high pressure of pellet formation, some samples can undergo a chemical change or an ion exchange reaction with the KBr. This is a known issue for certain types of salts (like amine hydrochlorides) and can result in a spectrum that does not represent the original material.

Making the Right Choice for Your Goal

The KBr method is a powerful, classic technique, but it is not always the best choice compared to modern alternatives like Attenuated Total Reflectance (ATR).

- If your primary focus is obtaining a high-quality, high-resolution transmission spectrum of a stable solid: The KBr method, when performed carefully, is an excellent choice that often yields superior data.

- If your primary focus is speed, ease of use, or non-destructive analysis: An ATR accessory is almost always a better option, as it requires minimal sample preparation and analyzes the surface of the sample directly.

- If your sample is sensitive to moisture, pressure, or is difficult to grind: Avoid the KBr method and use ATR to prevent sample degradation and ensure an accurate measurement.

Mastering the KBr pellet technique provides a powerful tool for obtaining clear and detailed molecular insights from solid materials.

Summary Table:

| Key Aspect | Description |

|---|---|

| Purpose | Sample preparation for transmission-mode IR analysis of solids |

| Core Material | Potassium bromide (KBr) - transparent in mid-IR range |

| Sample Ratio | Typically ~1% sample by weight in KBr matrix |

| Key Steps | Drying, grinding, pressing under high pressure with vacuum |

| Ideal For | High-resolution spectra of stable, dry solid compounds |

| Avoid For | Moisture-sensitive, pressure-sensitive, or difficult-to-grind samples |

Need reliable equipment for your KBr pellet preparation? KINTEK specializes in laboratory equipment and consumables, providing high-quality hydraulic presses, pellet dies, and agate mortars and pestles specifically designed for IR spectroscopy sample preparation. Our products help ensure your KBr pellets are clear, homogeneous, and free from moisture contamination—delivering the high-resolution spectra your research demands. Contact our experts today to discuss your specific lab needs and discover how KINTEK can enhance your analytical capabilities.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- kbr pellet press 2t

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

People Also Ask

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy