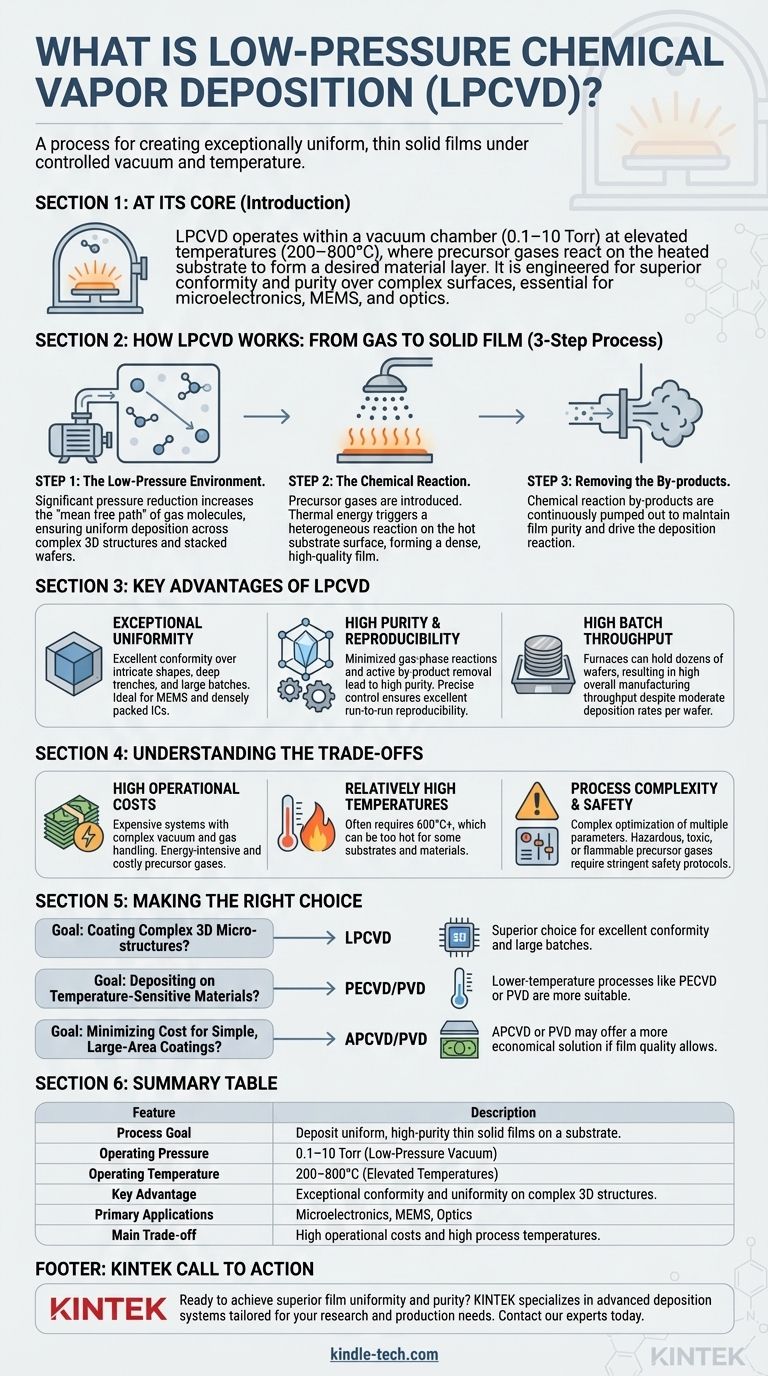

At its core, Low-Pressure Chemical Vapor Deposition (LPCVD) is a process used to create exceptionally uniform, thin solid films on a substrate. It operates within a vacuum chamber at low pressures (typically 0.1–10 Torr) and elevated temperatures (200–800°C), where chemical precursor gases react on the heated substrate surface to form the desired material layer.

LPCVD is not simply about depositing a film; it is a specialized technique engineered for achieving superior conformity and purity over complex surfaces. The low-pressure environment is the critical factor that enables the high-quality coatings essential for modern microelectronics, MEMS, and optics.

How LPCVD Works: From Gas to Solid Film

To understand LPCVD, it's best to break it down into its fundamental steps. The process is a carefully controlled chemical reaction occurring within a vacuum.

The Low-Pressure Environment

The defining feature of LPCVD is the vacuum. By significantly reducing the pressure in the chamber, gas molecules can travel much further before colliding with each other.

This increased "mean free path" ensures that the precursor gases deposit uniformly across all surfaces of the substrate, including complex 3D topographies and vertically stacked wafers.

The Chemical Reaction

Precursor gases, which contain the atoms of the desired film material, are introduced into the chamber, often through a "shower head" for even distribution.

The substrate itself is heated. This thermal energy triggers a heterogeneous chemical reaction, meaning the reaction occurs specifically on the hot surface of the substrate, not in the gas phase. This surface-specific reaction is key to forming a dense, high-quality film.

Removing the By-products

The chemical reactions that form the solid film also create gaseous by-products. These waste gases are continuously removed from the chamber by a vacuum pump system.

This constant removal is crucial for maintaining the purity of the film and driving the deposition reaction forward.

The Key Advantages of the LPCVD Method

Engineers choose LPCVD when certain film characteristics are non-negotiable. Its advantages are directly tied to the controlled, low-pressure environment.

Exceptional Film Uniformity

LPCVD offers excellent conformity, or "throwing power." It can produce a film of uniform thickness over intricate shapes, inside deep trenches, and across large batches of wafers.

This capability is what makes it indispensable for manufacturing devices like Micro-Electro-Mechanical Systems (MEMS) and densely packed integrated circuits.

High Purity and Reproducibility

Because reactions in the gas phase are minimized and by-products are actively removed, LPCVD films exhibit very high purity.

The process parameters—temperature, pressure, and gas flow—are precisely controlled, leading to excellent run-to-run reproducibility, a critical requirement for high-volume manufacturing.

High Batch Throughput

LPCVD furnaces are often designed to hold dozens or even hundreds of wafers at once, typically stacked vertically in a "boat."

While the deposition rate per wafer may be moderate, the ability to process a large batch simultaneously results in high overall throughput for manufacturing.

Understanding the Trade-offs and Limitations

No technique is perfect. The strengths of LPCVD are balanced by clear and important trade-offs that must be considered.

High Operational Costs

LPCVD systems are expensive. They require sophisticated vacuum pumps, high-temperature furnaces, and complex gas handling systems.

Furthermore, the process is energy-intensive, and the high-purity precursor gases can be very costly, contributing to a high overall cost of ownership.

Relatively High Temperatures

The process often requires temperatures of 600°C or higher. This can be too hot for substrates that have already undergone other processing steps or for materials like polymers that cannot withstand such heat.

Process Complexity and Safety

Achieving a repeatable, high-quality film requires precise control over multiple interacting parameters. The process can be complex to develop and optimize.

Additionally, many precursor gases used in LPCVD (such as silane or phosphine) are hazardous, toxic, or flammable, requiring stringent safety protocols and facility infrastructure.

Making the Right Choice for Your Goal

Selecting a deposition method requires aligning the technique's strengths with your project's primary objective. LPCVD is a powerful tool, but only for the right application.

- If your primary focus is coating complex 3D micro-structures with exceptional uniformity: LPCVD is the superior choice due to its excellent conformity and ability to process large batches.

- If your primary focus is depositing films on temperature-sensitive materials: A lower-temperature process like Plasma-Enhanced CVD (PECVD) or Physical Vapor Deposition (PVD) would be a more suitable option.

- If your primary focus is minimizing cost for simple, large-area coatings: Techniques like Atmospheric Pressure CVD (APCVD) or PVD may offer a more economical solution, provided their film quality meets your needs.

Understanding these core trade-offs empowers you to select the deposition technique that aligns perfectly with your specific engineering and economic goals.

Summary Table:

| Feature | Description |

|---|---|

| Process Goal | Deposit uniform, high-purity thin solid films on a substrate. |

| Operating Pressure | 0.1–10 Torr (Low-Pressure Vacuum) |

| Operating Temperature | 200–800°C (Elevated Temperatures) |

| Key Advantage | Exceptional conformity and uniformity on complex 3D structures. |

| Primary Applications | Microelectronics, MEMS, Optics |

| Main Trade-off | High operational costs and high process temperatures. |

Ready to achieve superior film uniformity and purity for your microelectronics or MEMS project? KINTEK specializes in advanced lab equipment, including deposition systems tailored for your research and production needs. Our expertise can help you select the right technology to meet your specific goals for conformity, throughput, and cost. Contact our experts today to discuss how we can support your laboratory's success.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs