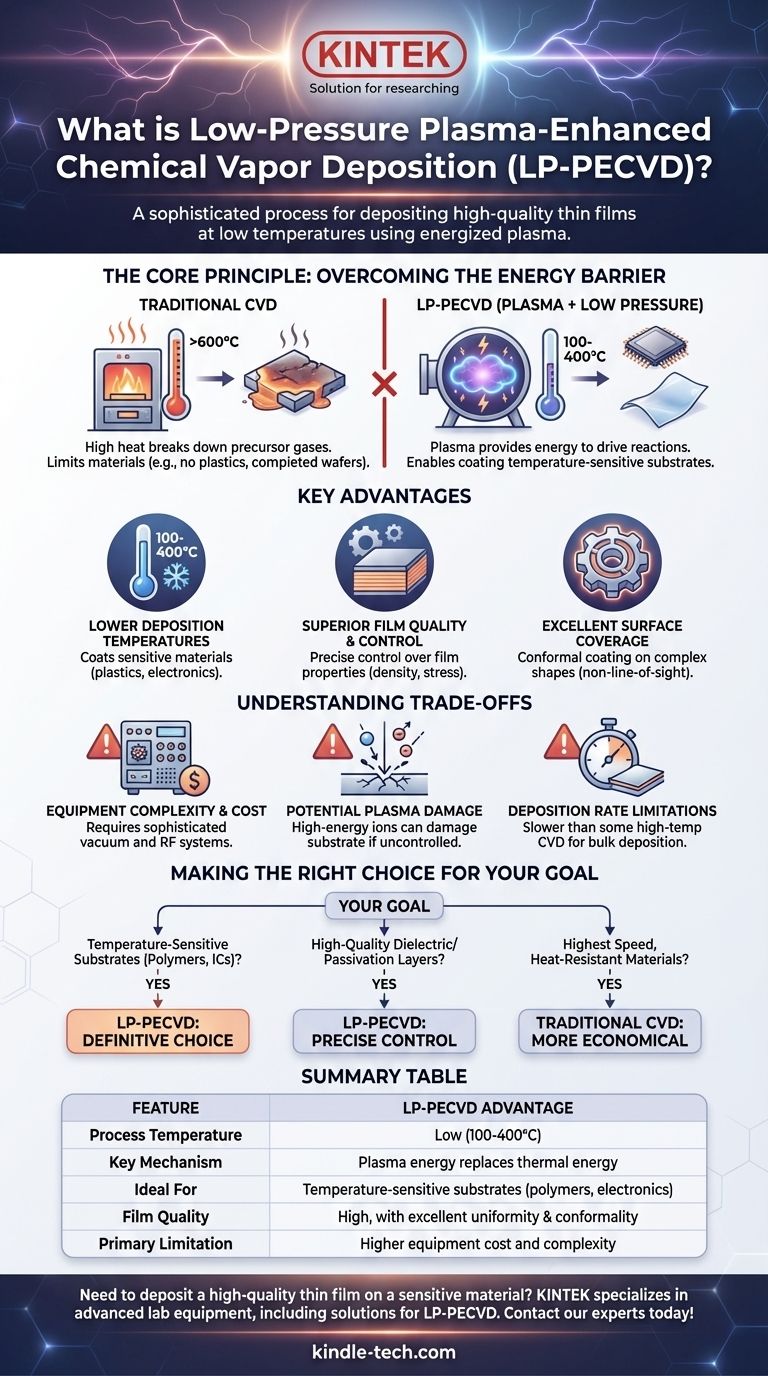

At its core, Low-Pressure Plasma-Enhanced Chemical Vapor Deposition (LP-PECVD) is a sophisticated process for depositing very thin, high-quality films onto a surface. It uses an energized gas, or plasma, to drive the necessary chemical reactions at low temperatures inside a vacuum chamber, a significant advantage over traditional methods that rely on extreme heat.

The central problem with many deposition methods is their reliance on high temperatures, which can damage sensitive materials like electronics or plastics. LP-PECVD solves this by replacing brute-force heat with the targeted energy of a plasma, enabling the creation of advanced materials under much gentler conditions.

The Core Principle: Overcoming the Energy Barrier

To understand LP-PECVD, it's essential to first grasp the limitations of conventional Chemical Vapor Deposition (CVD).

The Challenge of Traditional CVD

In standard CVD, precursor gases are flowed over a heated substrate. The intense heat provides the thermal energy needed to break down these gases, initiating a chemical reaction that deposits a solid film on the substrate's surface.

This method works well, but its reliance on high temperatures (often >600°C) severely limits the types of materials that can be coated. You cannot deposit a film on a polymer or a completed semiconductor wafer if the process temperature would melt or destroy it.

Introducing Plasma: The Energy Catalyst

LP-PECVD introduces a game-changing element: plasma. A plasma is created by applying a strong electric field to the precursor gas at low pressure, stripping electrons from the atoms and creating a highly reactive mix of ions, electrons, and neutral radicals.

This plasma is a reservoir of high energy. It provides the necessary energy to break the chemical bonds in the precursor gases and drive the deposition reaction, all without requiring the substrate to be intensely heated.

The Role of Low Pressure

Operating at low pressure (in a vacuum) is critical for two reasons. First, it makes it easier to initiate and sustain a stable plasma.

Second, it increases the mean free path—the average distance a particle travels before colliding with another. This allows the electrons and ions to accelerate and gain more energy from the electric field, making the plasma more efficient at dissociating the precursor gases for deposition.

Key Advantages of the LP-PECVD Process

By using plasma at low pressure, this technique offers distinct benefits that make it indispensable in modern manufacturing.

Lower Deposition Temperatures

This is the most significant advantage. By substituting plasma energy for thermal energy, deposition can occur at much lower temperatures (typically 100-400°C). This opens the door to coating temperature-sensitive substrates like plastics, glass, and complex electronic devices.

Superior Film Quality and Control

The plasma environment allows for precise control over the deposition process. Engineers can fine-tune the plasma's power, gas flow, and pressure to meticulously control the properties of the resulting film, such as its density, refractive index, and internal stress.

Excellent Surface Coverage

Like other CVD methods, LP-PECVD is not a "line-of-sight" process, unlike many Physical Vapor Deposition (PVD) techniques. The precursor gases and reactive species surround the substrate, allowing for highly uniform and conformal coatings on complex, three-dimensional shapes.

Understanding the Trade-offs

While powerful, LP-PECVD is not a universal solution. It involves specific complexities and limitations that must be considered.

Equipment Complexity and Cost

Generating a stable plasma inside a vacuum chamber requires sophisticated and expensive equipment, including RF power supplies, matching networks, and robust vacuum systems. This makes the initial capital investment higher than for some simpler atmospheric pressure techniques.

Potential for Plasma-Induced Damage

The high-energy ions within the plasma can, if not properly controlled, physically bombard and damage the substrate or the growing film. This requires careful process design to balance the benefits of plasma activation against the risk of ion damage.

Deposition Rate Limitations

Compared to some high-temperature thermal CVD processes designed for bulk deposition, LP-PECVD can have a lower deposition rate. It is optimized for creating thin, high-quality functional films, not for rapidly applying very thick coatings.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on the specific requirements of your application, balancing material constraints, performance needs, and cost.

- If your primary focus is coating temperature-sensitive substrates like polymers or integrated circuits: LP-PECVD is the definitive choice due to its low-temperature processing.

- If your primary focus is creating highly uniform, high-quality dielectric or passivation layers for electronics and optics: LP-PECVD provides the precise control necessary for these demanding applications.

- If your primary focus is achieving the highest possible deposition speed on simple, heat-resistant materials: A conventional high-temperature CVD process may be a more direct and economical solution.

Ultimately, LP-PECVD empowers the creation of advanced thin films on materials that would be impossible to coat with traditional high-temperature methods.

Summary Table:

| Feature | LP-PECVD Advantage |

|---|---|

| Process Temperature | Low (100-400°C) |

| Key Mechanism | Plasma energy replaces thermal energy |

| Ideal For | Temperature-sensitive substrates (polymers, electronics) |

| Film Quality | High, with excellent uniformity and conformality |

| Primary Limitation | Higher equipment cost and complexity |

Need to deposit a high-quality thin film on a sensitive material? KINTEK specializes in advanced lab equipment, including solutions for low-pressure plasma-enhanced chemical vapor deposition (LP-PECVD). Our expertise can help you achieve precise, low-temperature coatings for polymers, electronics, and optics. Contact our experts today to discuss how we can meet your specific laboratory deposition needs!

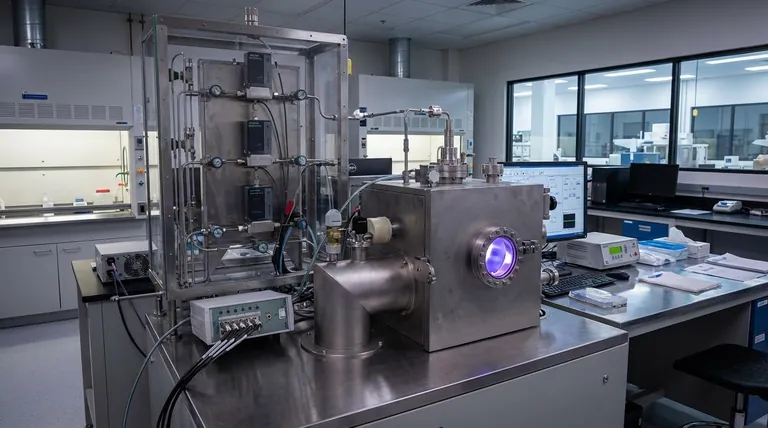

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- How does radio frequency (RF) power affect the PECVD process? Master Ionization for Superior Thin Film Quality

- What is the process of PACVD? Achieve High-Quality Coatings at Lower Temperatures

- What is the PECVD technique? Unlock Low-Temperature Thin Film Deposition

- How does post-treatment in an annealing furnace improve PECVD a-SiC thin films? Achieve Superior Material Stability

- How does Radio Frequency Enhanced Plasma Chemical Vapour Deposition (RF-PECVD) work? Learn the Core Principles

- How does a 13.56 MHz radio frequency (RF) power supply facilitate the densification of organosilicon films?

- What is plasma-enhanced atomic layer deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is the pressure for PECVD? Mastering the Key Parameter for Thin Film Quality