At its core, magnetron plasma is a highly energized, ionized gas that is uniquely confined by magnetic fields within a vacuum chamber. This plasma is generated by applying a high voltage in a low-pressure inert gas, such as argon, creating the ideal conditions to physically eject atoms from a target material and deposit them as a thin film onto a substrate.

While any plasma is an ionized gas, magnetron plasma is distinct because it uses magnetic fields to trap electrons near the source material. This dramatically intensifies the ionization process, creating a dense and highly efficient plasma that enables rapid, uniform, and high-quality surface coatings.

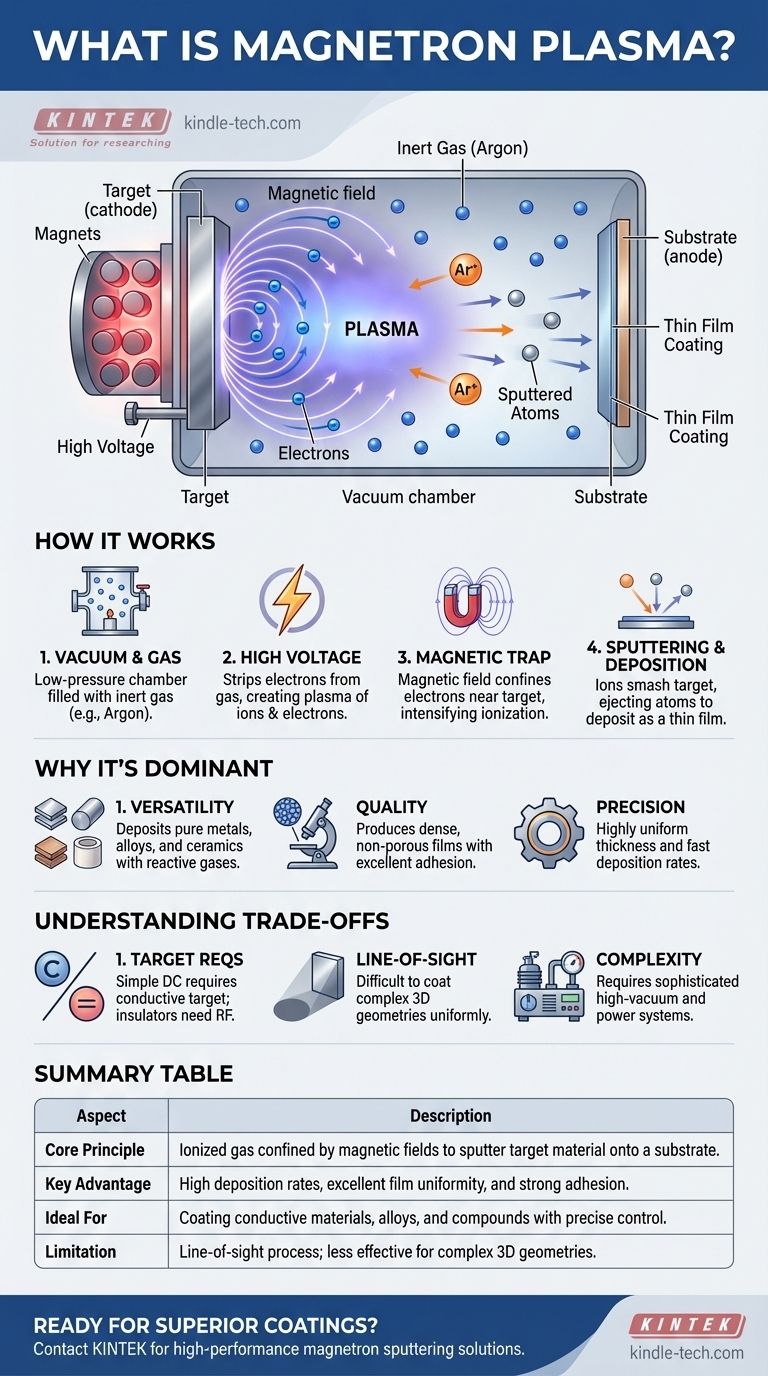

How Magnetron Plasma is Generated and Utilized

To understand magnetron plasma, you must first understand the process it enables: magnetron sputtering. The plasma is not the end goal, but the critical tool that makes the entire process work.

The Initial Setup: A Vacuum Environment

The process begins in a vacuum chamber containing a substrate (the object to be coated) and a target (the material you want to deposit). The chamber is filled with a small amount of an inert gas, most commonly argon.

The Spark: Applying High Voltage

A large negative voltage is applied to the target, which acts as the cathode. This high voltage field energizes the chamber, stripping electrons from the neutral argon gas atoms. This creates a plasma composed of free electrons and positively charged argon ions.

The "Magnetron" Secret: Magnetic Confinement

This is the key innovation. Magnets placed behind the target create a magnetic field in front of it. This field traps the lightweight electrons, forcing them into a spiral path close to the target's surface instead of allowing them to escape.

The Cascade Effect: Efficient Sputtering

These trapped electrons collide with many more neutral argon atoms, creating an avalanche of ionization. This results in a very dense, localized plasma right where it's needed. The heavy, positive argon ions are then accelerated by the electric field and smash into the target, dislodging or "sputtering" atoms of the target material. These sputtered atoms travel through the vacuum and deposit onto the substrate, forming a thin, uniform film.

Why This Process is a Dominant Technology

The efficiency of magnetron plasma directly translates into significant advantages for industrial manufacturing and research, making it a cornerstone of thin-film deposition.

Unmatched Material Versatility

As the sputtering process is purely physical, it can be used to deposit a vast range of materials. This includes pure metals, complex alloys, and even ceramics and other compounds when a reactive gas (like oxygen or nitrogen) is introduced.

Exceptional Film Quality and Adhesion

The sputtered atoms arrive at the substrate with high kinetic energy. This energy helps them form a very dense, non-porous film with excellent adhesion, as the arriving atoms can embed themselves slightly into the substrate surface.

Precision, Uniformity, and Speed

The magnetic confinement creates a stable and predictable plasma, allowing for precise control over the deposition rate. This results in films with highly uniform thickness across large areas, deposited at a much faster rate than non-magnetron sputtering methods.

Understanding the Trade-offs

While powerful, the magnetron sputtering process is not without its specific requirements and limitations. Objectivity requires acknowledging them.

Target Material Requirements

For the simplest setup (DC sputtering), the target material must be electrically conductive to prevent a build-up of positive charge on its surface, which would halt the process. Depositing insulating materials requires more complex and expensive RF (Radio Frequency) power supplies.

Line-of-Sight Deposition

Sputtering is a "line-of-sight" process. The sputtered atoms travel in relatively straight lines from the target to the substrate. This makes it difficult to uniformly coat complex, three-dimensional objects with undercuts or hidden surfaces.

System Complexity

Industrial magnetron sputtering systems are sophisticated pieces of equipment. They require high-vacuum pumps, precise gas flow controllers, high-voltage power supplies, and powerful magnets, representing a significant capital investment.

How to Apply This to Your Project

Your choice of a deposition technology depends entirely on your final goal. Magnetron sputtering is a powerful tool when used for the right application.

- If your primary focus is high-throughput industrial coating: Magnetron sputtering is a leading choice due to its high deposition rates, scalability, and the quality of the resulting films.

- If your primary focus is depositing complex alloys or reactive compounds: The ability to co-sputter from multiple targets and introduce reactive gases gives you precise control over the final film's composition.

- If your primary focus is coating intricate 3D geometries or highly sensitive substrates: Be aware of the line-of-sight limitations and consider alternatives like Atomic Layer Deposition (ALD) or electroplating, which may be better suited for conformal coating.

Ultimately, understanding that magnetron plasma is a magnetically enhanced tool is the key to leveraging one of the most versatile processes in modern materials science.

Summary Table:

| Aspect | Description |

|---|---|

| Core Principle | Ionized gas confined by magnetic fields to sputter target material onto a substrate. |

| Key Advantage | High deposition rates, excellent film uniformity, and strong adhesion. |

| Ideal For | Coating conductive materials, alloys, and compounds with precise control. |

| Limitation | Line-of-sight process; less effective for complex 3D geometries. |

Ready to achieve superior thin-film coatings for your lab or production line? KINTEK specializes in high-performance magnetron sputtering equipment and consumables, delivering the precision and reliability your laboratory demands. Contact our experts today to discuss how our solutions can enhance your coating process and material outcomes.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials