At its core, Physical Vapor Deposition (PVD) is a vacuum-based coating process where a solid material is vaporized and then condensed onto a substrate's surface to form an extremely thin, high-performance film. This entire process—from vaporizing the source material to depositing it as a solid layer—occurs in a high-vacuum chamber to ensure the purity and quality of the final coating.

The crucial insight is that PVD is a fundamentally physical process, not a chemical one. Atoms from a source material are physically transferred onto a surface, much like how steam condenses on a cold mirror. This distinction from chemical-based methods governs its unique applications and outcomes.

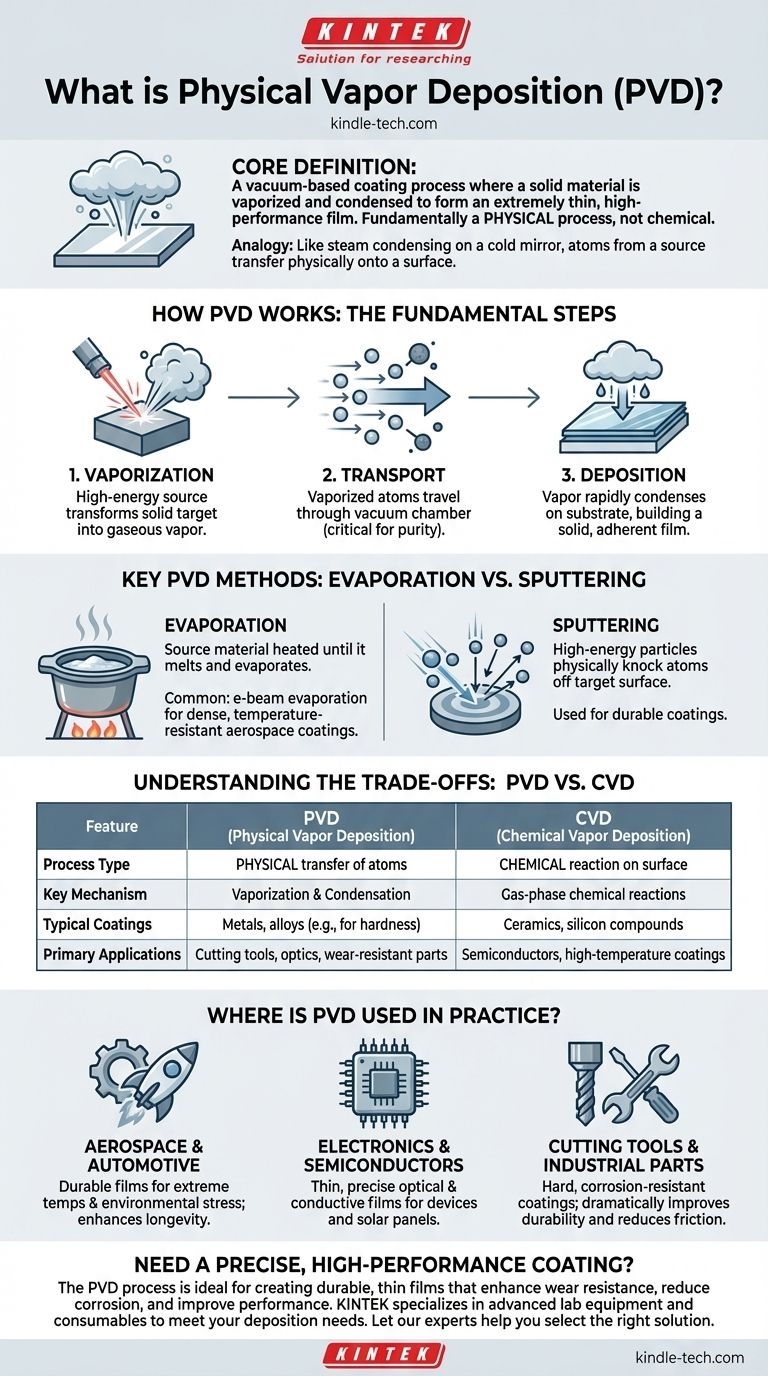

How PVD Works: The Fundamental Steps

The PVD process, regardless of the specific technique used, follows a consistent three-step sequence within a vacuum chamber.

Step 1: Vaporization

A high-energy source is used to bombard a solid target material. This energy input is significant enough to transform the solid material directly into a gaseous vapor.

Step 2: Transport

The vaporized atoms or molecules travel through the vacuum chamber. The vacuum is critical because it removes other particles, ensuring the vaporized material has an unobstructed path to the target substrate without reacting with air or other contaminants.

Step 3: Deposition

When the vaporized material reaches the cooler surface of the substrate (the object being coated), it rapidly condenses. This condensation builds a thin, solid, and highly adherent film on the substrate's surface, one atomic layer at a time.

Key PVD Methods: Evaporation vs. Sputtering

While the goal is the same, the method of vaporization creates two primary categories of PVD.

Evaporation

In this method, the source material is heated in the vacuum until it melts and evaporates. This vapor then travels to and condenses on the substrate. A common technique is e-beam evaporation, used by aerospace companies to create dense, temperature-resistant coatings on critical components.

Sputtering

Sputtering is a mechanical process on a microscopic scale. The target material is struck by high-energy particles (typically ions of an inert gas). This collision physically knocks atoms off the surface of the target, which then deposit onto the substrate.

Understanding the Trade-offs: PVD vs. CVD

To truly understand PVD, it is essential to compare it to its counterpart, Chemical Vapor Deposition (CVD).

The Core Difference: Physical vs. Chemical

PVD is a physical process. It involves the direct movement and deposition of atoms from a source to a target. In contrast, CVD is a chemical process. It introduces one or more gaseous molecules that undergo a chemical reaction directly on the substrate's surface, forming a new, solid material.

Process Conditions

PVD typically involves heating the source material to its melting or vaporization point to generate the vapor. CVD relies on exposing a hot workpiece to reactive gases within a vacuum, where the surface temperature triggers the desired chemical reaction.

Material & Application Suitability

PVD is extremely versatile and is a preferred method for depositing metals and other elements to create hard, corrosion-resistant coatings on tools or optical films for solar panels. CVD is often used when the coating material itself needs to be formed by the reaction of two or more gases on the surface.

Where is PVD Used in Practice?

PVD is not an abstract laboratory technique; it is a critical manufacturing process used to enhance products we interact with daily.

Aerospace and Automotive

Components are coated with PVD to provide dense, durable films that can withstand extreme temperatures and environmental stress, significantly enhancing part longevity.

Electronics and Semiconductors

PVD is used to apply incredibly thin and precise optical and conductive films required for manufacturing semiconductors, solar panels, and various electronic displays.

Cutting Tools and Industrial Parts

A common application is applying hard, corrosion-resistant coatings to industrial cutting tools, drills, and dies. This dramatically improves their durability, reduces friction, and extends their operational life in harsh environments.

Making the Right Choice for Your Goal

Selecting the right deposition technology depends entirely on the desired outcome for the final product.

- If your primary focus is extreme hardness and wear resistance on a metal part: PVD, particularly sputtering, is an industry standard for creating robust, durable coatings.

- If your primary focus is creating a pure, dense, temperature-resistant film for aerospace or optics: PVD via e-beam evaporation provides exceptional control and quality.

- If your primary focus is creating a coating from gaseous precursors via a surface reaction: You should investigate Chemical Vapor Deposition (CVD) as the more appropriate method.

Ultimately, understanding the physical nature of PVD is the key to leveraging its power to engineer surfaces with unparalleled precision and performance.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical transfer of atoms | Chemical reaction on the surface |

| Key Mechanism | Vaporization and condensation | Gas-phase chemical reactions |

| Typical Coatings | Metals, alloys (e.g., for hardness) | Ceramics, silicon compounds |

| Primary Applications | Cutting tools, optics, wear-resistant parts | Semiconductors, high-temperature coatings |

Need a precise, high-performance coating for your lab equipment or industrial components? The PVD process is ideal for creating durable, thin films that enhance wear resistance, reduce corrosion, and improve performance. At KINTEK, we specialize in providing advanced lab equipment and consumables to meet your specific deposition needs. Let our experts help you select the right solution for your application. Contact us today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the advantages of using a hot-wall CVD reactor? Optimize Tantalum Carbide Coatings for Semiconductor Purity

- How is metal deposited on a surface using sputter deposition? A Guide to High-Quality Thin Film Coating

- Why is vacuum needed for thin film deposition? To Achieve Purity, Uniformity, and Control

- What is the meaning of deposition of vapor? A Guide to Thin-Film Coating Technologies

- What role does the substrate heating stage play in ALD of aluminum oxide? Mastering the Thermal Process Window

- What are the advantages and disadvantages of sputtering? Balancing Film Quality, Speed, and Cost

- What is deposition in semiconductor manufacturing? Building the Microscopic Layers of Modern Chips

- What is the ion beam sputtering method? Achieve Unmatched Precision in Thin Film Deposition