At its core, MOCVD equipment is a highly specialized system for growing complex, multi-layered crystalline films with atomic-level precision. This process, also known as Metal-Organic Vapor Phase Epitaxy (MOVPE), is the foundational technology for manufacturing high-performance devices like light-emitting diodes (LEDs), lasers, solar cells, and high-frequency electronics. It works by introducing specific gases into a reactor chamber to deposit a perfect, single-crystal layer of material onto a substrate wafer.

MOCVD is not simply a coating machine; it is a crystal growth reactor. Its unique ability to precisely control the deposition of atomic layers is what enables the fabrication of high-efficiency optical and electronic devices that are otherwise impossible to create.

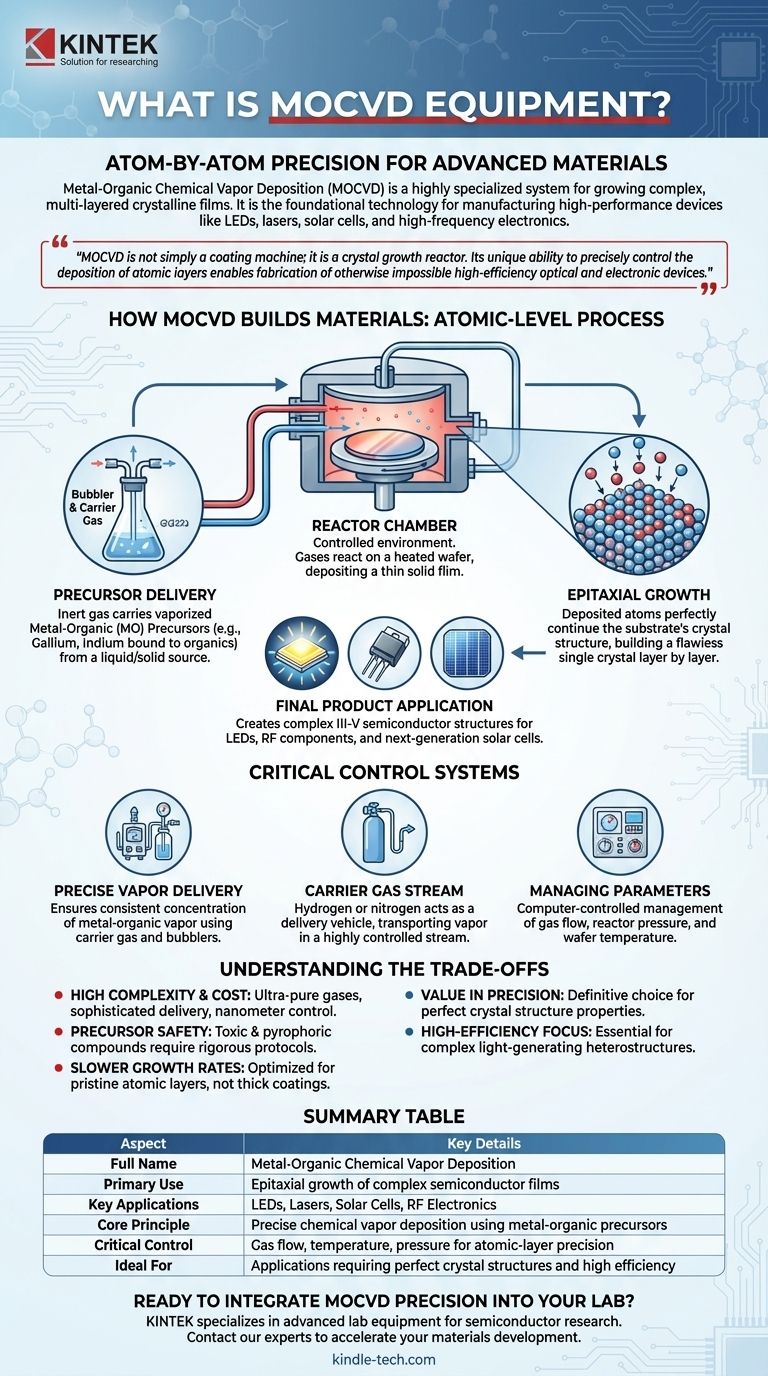

How MOCVD Builds Materials Atom by Atom

The MOCVD process is fundamentally about controlled chemical reactions that result in a perfect crystalline structure. This precision is what makes the technology so powerful.

The Core Principle: Chemical Vapor Deposition

MOCVD is a specific type of chemical vapor deposition. The basic idea is to inject carefully chosen precursor gases into a heated chamber containing a wafer. The heat causes the gases to react and decompose, depositing a thin, solid film of the desired material onto the wafer's surface.

Using Metal-Organic Precursors

The "MO" in MOCVD stands for metal-organic. The precursor gases are complex molecules where metal atoms (like gallium, indium, or aluminum) are bound to organic compounds. These molecules are designed to be volatile, meaning they easily turn into a vapor that can be transported into the reactor.

The Reactor Chamber Environment

The reactor is a highly controlled environment. The temperature of the wafer and the pressure inside the chamber are meticulously managed to dictate how the chemical reactions proceed. This control ensures the deposited atoms arrange themselves correctly.

Achieving Epitaxial Growth

The ultimate goal of MOCVD is epitaxial growth. This means the new atoms being deposited arrange themselves in a way that perfectly continues the crystal lattice structure of the wafer underneath. The result is not just a coating, but a single, flawless crystal built layer by layer.

The Critical Control Systems

The quality of an MOCVD-grown material depends entirely on the equipment's ability to maintain absolute control over every variable in the process. This is what makes the technology so sophisticated.

Precise Vapor Delivery

Many metal-organic precursors are liquids or solids at room temperature. A system, often a bubbler, is used to turn them into a vapor with a consistent concentration. An inert carrier gas is bubbled through the liquid precursor, picking up a predictable amount of the vapor.

The Carrier Gas Stream

A carrier gas (such as hydrogen or nitrogen) acts as the delivery vehicle. It flows through the bubbler, carries the metal-organic vapor, and transports it into the reactor chamber in a highly controlled stream.

Managing Flow, Temperature, and Pressure

The final film's properties are determined by the exact ratio of gases, the growth time, and the growth rate. This requires precise, computer-controlled management of gas flow rates, reactor pressure, and wafer temperature to ensure the process is repeatable and efficient.

Understanding the Trade-offs

While incredibly powerful, MOCVD is a specialized process with inherent complexities that are important to recognize. Its value is in precision, not speed or low cost.

High Complexity and Cost

The need for ultra-pure gases, sophisticated precursor delivery systems, and nanometer-level control over temperature and pressure makes MOCVD equipment exceptionally complex and expensive to purchase and operate.

Precursor Handling and Safety

The metal-organic compounds used in the process can be highly toxic and pyrophoric (igniting spontaneously in air). This necessitates rigorous safety protocols, specialized handling equipment, and extensive facility infrastructure.

Slower Growth Rates

Because MOCVD is designed for building pristine atomic layers, it is a relatively slow process compared to bulk deposition methods. It is optimized for creating thin, complex, high-value films, not for applying thick, simple coatings.

Making the Right Choice for Your Goal

MOCVD is not a universal solution; it is the definitive choice when the electronic or optical properties of a perfect crystal structure are non-negotiable.

- If your primary focus is high-efficiency LEDs and lasers: MOCVD is essential for creating the complex III-V semiconductor structures, known as heterostructures, that generate light effectively.

- If your primary focus is high-frequency RF components: This technology enables the growth of specialized compound semiconductors needed for the transistors in advanced communication devices.

- If your primary focus is next-generation solar cells or photodetectors: MOCVD provides the atomic-level control required to build the multi-junction devices that maximize light absorption and conversion efficiency.

Ultimately, MOCVD equipment transforms simple chemical vapors into the high-performance crystalline heart of modern optical and electronic technology.

Summary Table:

| Aspect | Key Details |

|---|---|

| Full Name | Metal-Organic Chemical Vapor Deposition |

| Primary Use | Epitaxial growth of complex semiconductor films |

| Key Applications | LEDs, Lasers, Solar Cells, RF Electronics |

| Core Principle | Precise chemical vapor deposition using metal-organic precursors |

| Critical Control | Gas flow, temperature, pressure for atomic-layer precision |

| Ideal For | Applications requiring perfect crystal structures and high efficiency |

Ready to Integrate MOCVD Precision into Your Lab?

KINTEK specializes in providing advanced lab equipment and consumables for semiconductor research and production. Our expertise in MOCVD systems can help you achieve the atomic-level control needed for next-generation LEDs, lasers, and electronic devices.

Contact our experts today to discuss how our solutions can accelerate your materials development and manufacturing processes.

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What is thermal vapour deposition for thin films? A Simple Guide to High-Purity Coatings

- What is epitaxy growth of graphene? A Guide to High-Quality, Large-Area Production

- What is the process of deposition in semiconductors? Build Precise Thin Films for Your ICs

- What is the growth mechanism of graphene? Mastering CVD for High-Quality, Large-Area Production

- What is the process of aluminum sputtering? A Guide to Thin Film Deposition

- What are the methods used to deposit thin films? A Guide to Physical vs. Chemical Deposition

- Which deposition technique is used for metals? A Guide to PVD Methods for Thin Film Coating

- Which substrates are considered superior for the CVD of graphene? Choosing Copper vs. Nickel for High-Quality Growth