At its core, a muffle furnace is a high-temperature oven that excels at one critical task: heating a material in a completely isolated and controlled environment. It uses an inner chamber, or "muffle," to separate the item being heated from the heating elements and any potential contaminants, ensuring process purity and precise, uniform temperatures.

The defining characteristic of a muffle furnace is its design principle of isolation. By placing materials inside a separate, sealed chamber, it guarantees that the heating process is free from contamination and that the temperature is applied evenly across the entire workpiece.

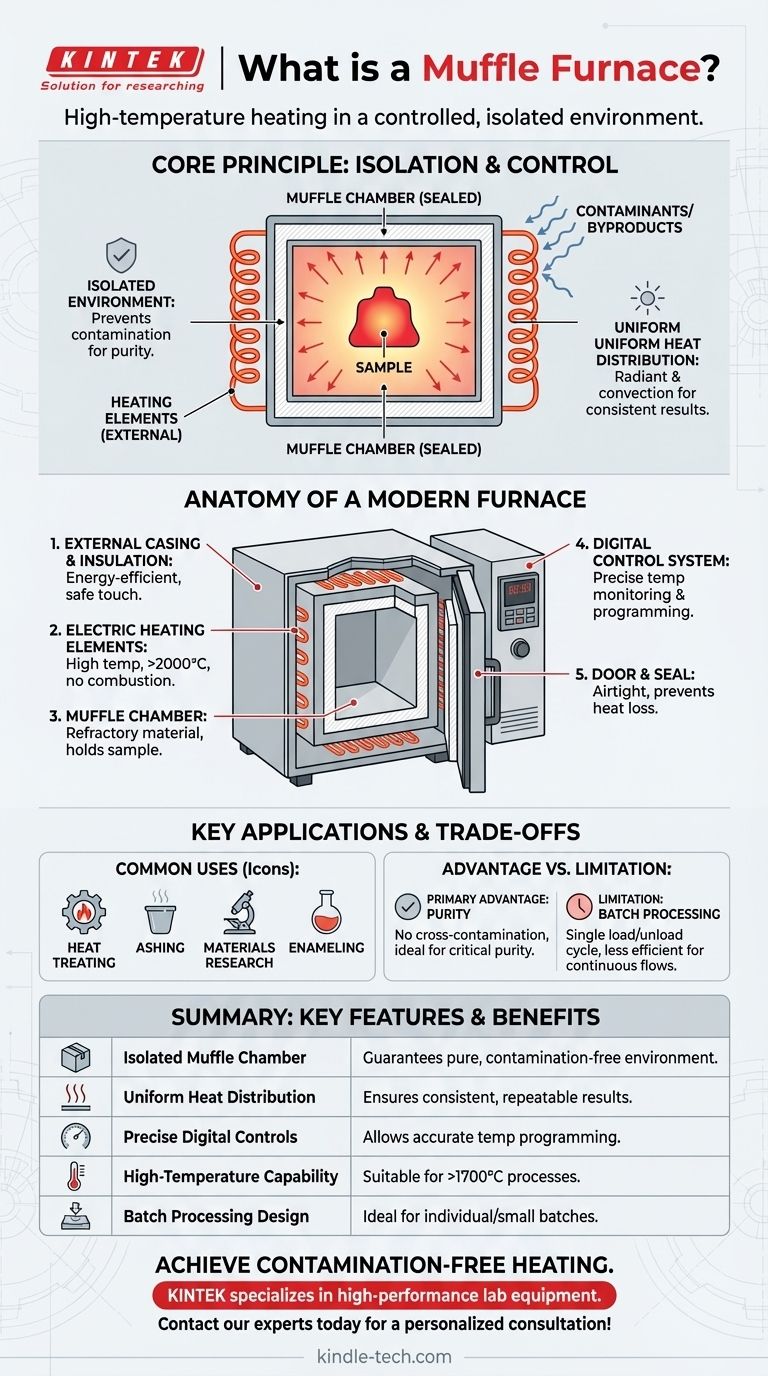

The Core Principle: Isolation and Control

The name "muffle furnace" comes from its most important feature. Understanding this concept is key to understanding its value in both laboratory and industrial settings.

The "Muffle" Chamber

A muffle is a dedicated, sealed chamber made from high-temperature refractory materials like silica and aluminum. This chamber houses the materials or samples to be heated.

Its purpose is to act as a barrier, ensuring the internal atmosphere remains pure and stable throughout the heating, holding, and cooling cycle.

Separation from Contaminants

This barrier is what makes a muffle furnace unique. It separates the workpiece from the heat source itself.

In older fuel-fired models, this prevented byproducts of combustion from contaminating the sample. In modern electric furnaces, it prevents direct contact with the heating elements, which is crucial for delicate processes.

Uniform Heat Distribution

The muffle chamber heats up and then radiates that heat evenly from all sides. This combination of radiant and convection heat transfer ensures a homogeneous treatment of the workpiece.

This uniform heating eliminates hot spots and guarantees that the entire sample experiences the same temperature profile, which is critical for consistent and repeatable results.

Anatomy of a Modern Muffle Furnace

While the design can vary, most modern muffle furnaces share a set of key components engineered for efficiency, safety, and precision.

The External Casing and Insulation

The outer body is typically a box-shaped steel enclosure. Between this casing and the inner chamber are layers of high-density insulating material, often ceramic fiber.

This insulation is vital for preventing heat loss, making the furnace highly energy-efficient and keeping the exterior safe to touch.

High-Temperature Heating Elements

Modern furnaces rely on electric heating elements that can achieve very high temperatures, sometimes exceeding 2000°C.

These elements are positioned outside the muffle chamber, heating it from the exterior. This design eliminates combustion byproducts entirely, offering superior control and a cleaner operating environment.

The Temperature Control System

A sensor, typically a thermocouple, is placed inside the chamber to constantly monitor the internal temperature.

This sensor feeds data to an external digital control panel, which precisely regulates the power sent to the heating elements. This allows operators to program specific temperature ramps, holds, and cooling rates.

The Furnace Door and Seal

The door is a critical component for maintaining the isolated atmosphere. It is heavily insulated and features a multi-layer seal, often with an inner ceramic fiber rope and an outer silicone ring.

A robust locking mechanism, such as a multi-point handwheel, ensures an airtight seal that prevents heat from escaping and air from entering the chamber.

Understanding Key Applications and Trade-offs

The unique design of a muffle furnace makes it ideal for certain tasks but less suitable for others.

Common Industrial and Lab Uses

The ability to heat in a pure, controlled atmosphere makes these furnaces indispensable for processes like:

- Heat treating metals such as steel and copper.

- Ashing samples to determine inorganic content.

- Materials research and testing.

- Enameling and glass fusing.

The Primary Advantage: Purity

The single greatest benefit is the prevention of cross-contamination. When the absolute purity of the final product is essential, a muffle furnace is the standard choice. Its isolated chamber guarantees that the only thing affecting the material is the heat itself.

The Limitation: Batch Processing

Most muffle furnaces are designed for batch processing. They have a single door for loading and unloading, meaning the process must be completed and the furnace cooled before the next batch can begin.

This makes them less efficient for high-volume, continuous production lines where a tunnel furnace might be more appropriate.

Making the Right Choice for Your Goal

Selecting the right heating equipment depends entirely on the specific requirements of your process.

- If your primary focus is sample purity and avoiding contamination: The isolated muffle chamber is the most important feature, making this furnace the ideal choice.

- If your primary focus is precise and uniform temperature control: The combination of an insulated chamber and modern digital controls delivers highly consistent and repeatable results.

- If your primary focus is high-temperature batch processing: The stationary, self-contained design is perfect for treating individual items or small batches that require a stable environment.

Ultimately, a muffle furnace is the definitive tool for achieving clean, controlled, and uniform high-temperature heating for critical applications.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Isolated Muffle Chamber | Guarantees a pure, contamination-free heating environment. |

| Uniform Heat Distribution | Ensures consistent, repeatable results across the entire sample. |

| Precise Digital Controls | Allows for accurate programming of temperature ramps and holds. |

| High-Temperature Capability | Suitable for demanding processes exceeding 1700°C. |

| Batch Processing Design | Ideal for individual items or small batches requiring a stable environment. |

Ready to achieve contamination-free heating in your lab?

For processes where sample purity and precise temperature control are non-negotiable—such as ashing, heat treatment, or materials testing—the right muffle furnace is critical. KINTEK specializes in high-performance lab equipment, including a range of muffle furnaces designed for reliability and accuracy.

We can help you:

- Select the perfect furnace for your specific temperature and chamber size requirements.

- Enhance the consistency and purity of your high-temperature processes.

- Improve your lab's efficiency with robust and energy-efficient equipment.

Let's find the right solution for your application. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the use of muffle furnace in food lab? Essential for Accurate Ash Content Analysis

- What is a muffle furnace used to measure? Unlock Precise Sample Analysis with High-Temp Heating

- What is the difference between an oven and a muffle? Choose the Right Heating Tool for Your Lab

- What is the difference between a muffle furnace and a drying oven? Choose the Right Tool for Your Lab

- What is a muffle furnace and its uses? Achieve Contamination-Free High-Temperature Processing