At its core, a muffle furnace is used for high-temperature heating applications where the material being processed must be isolated from the fuel and combustion byproducts of the heat source. This controlled environment makes it indispensable for a wide range of tasks, from heat-treating metals and sintering ceramics to performing precise chemical analysis on samples in a laboratory.

The true value of a muffle furnace lies not just in its ability to generate high heat, but in its capacity to do so within a chemically isolated chamber. This prevents contamination and ensures uniform, repeatable results for either transforming a material's properties or analyzing its composition.

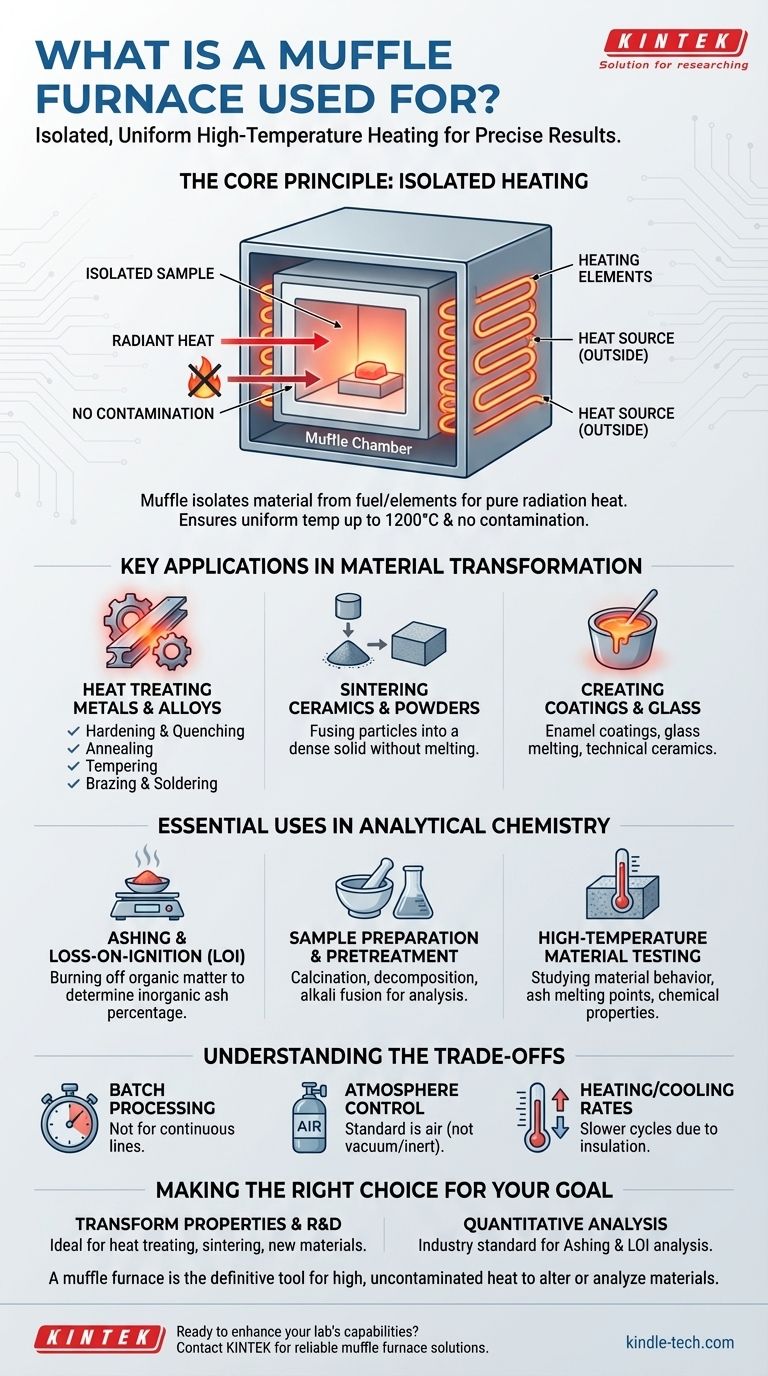

The Core Principle: Isolated, High-Temperature Heating

A muffle furnace's unique utility comes from its design. Understanding this principle is key to knowing why it's chosen for so many different applications.

What "Muffle" Means

The term "muffle" refers to the furnace's inner chamber, which is typically made of a high-temperature ceramic material. This chamber encloses the workpiece or sample.

Heating elements are positioned on the outside of this chamber. This design ensures that the material inside is heated by pure radiation and convection, completely isolated from any flame or electrical components.

This isolation is the furnace's defining feature, preventing any contamination that could alter the results of a sensitive analysis or the properties of a delicate material.

Achieving Uniform and Precise Temperatures

Muffle furnaces are engineered to reach and maintain very high temperatures, often up to 1200°C (2192°F) or higher, with exceptional accuracy.

The enclosed design promotes uniform heat distribution, ensuring that the entire sample experiences the same temperature. This is critical for processes like annealing or sintering where inconsistent heating would ruin the final product.

Key Applications in Material Transformation

Many industrial and research processes rely on muffle furnaces to fundamentally change the physical or chemical properties of a material.

Heat Treating Metals and Alloys

This is a primary application where the furnace's controlled environment is paramount. Processes include:

- Hardening & Quenching: Heating a metal to a specific temperature and then rapidly cooling it to increase hardness.

- Annealing: Heating and then slowly cooling a metal to soften it and relieve internal stresses.

- Tempering: Heating a previously hardened metal to a lower temperature to reduce brittleness.

- Brazing & Soldering: Joining metal components using a filler metal at high temperatures.

Sintering Ceramics and Powders

Sintering is the process of compacting and forming a solid mass of material by heat, without melting it to the point of liquefaction.

A muffle furnace provides the sustained, uniform high temperatures needed to fuse ceramic, metal, or composite powders into a dense, solid object.

Creating Coatings and Glass

The furnace is used to apply enamel coatings to metal surfaces, which requires melting glassy powders into a smooth, durable layer.

It is also used in laboratories and artisan workshops for melting glass, creating technical ceramics, and synthesizing special alloys in a controlled, small-batch environment.

Essential Uses in Analytical Chemistry and Research

In a laboratory setting, the muffle furnace is a standard tool for preparing and analyzing samples where organic material must be removed without losing the inorganic components.

Ashing and Loss-on-Ignition

Ashing is the most common analytical use. A sample is heated to a high temperature to completely burn off all organic and volatile substances.

What remains is the incombustible ash (inorganic residue). By weighing the sample before and after ashing, analysts can precisely determine the percentage of non-combustible material. This is a critical quality control step in fields like food science, environmental analysis, and materials research.

Sample Preparation and Pretreatment

Muffle furnaces are used to prepare samples for further, more complex analysis.

This can involve calcination (decomposing a material with heat), decomposing organic materials in medical or environmental samples, or performing an alkali fusion to dissolve refractory minerals for chemical testing.

High-Temperature Material Testing

Researchers use muffle furnaces to study how materials behave at extreme temperatures. This includes determining the ash melting point of coal, testing the durability of technical ceramics, or observing the chemical properties of a substance as it is heated.

Understanding the Trade-offs

While incredibly versatile, a muffle furnace is not the right tool for every heating task. Its design comes with specific limitations.

Limitation: Batch Processing

Most muffle furnaces are designed for batch processing. You load a sample, run a heating cycle, cool it down, and then remove the sample. This is not suitable for continuous, high-volume industrial production lines, which require tunnel furnaces.

Limitation: Atmosphere Control

A standard muffle furnace isolates the sample from combustion gases, but the atmosphere inside the muffle is still air. For processes that require a specific atmosphere (such as inert argon gas or a vacuum), a more specialized and expensive furnace is required.

Consideration: Heating and Cooling Rates

Compared to direct heating methods, muffle furnaces can have slower heating and cooling cycles due to the thermal mass of the insulating chamber. This can be an advantage for processes like annealing that require slow cooling, but a disadvantage when rapid cycles are needed.

Making the Right Choice for Your Goal

Selecting a muffle furnace is about matching its core strengths—isolated and uniform high heat—to your specific objective.

- If your primary focus is transforming material properties: The muffle furnace is the ideal tool for heat treating metals, sintering ceramics, or creating coatings where clean, uniform heat is non-negotiable for a quality result.

- If your primary focus is quantitative analysis: It is the industry standard for ashing, loss-on-ignition analysis, and accurately determining the inorganic or volatile content of a sample.

- If your primary focus is creating new materials: Its controlled environment makes it perfect for laboratory-scale research and development of novel ceramics, alloys, and glass compositions.

Ultimately, a muffle furnace is the definitive tool when you require high, uncontaminated heat to reliably alter or analyze a material.

Summary Table:

| Application Category | Key Processes | Primary Benefit |

|---|---|---|

| Material Transformation | Heat treating metals, sintering ceramics, creating coatings | Isolated, uniform heating for property alteration |

| Analytical Chemistry | Ashing, loss-on-ignition, sample preparation | Contamination-free environment for accurate analysis |

| Research & Development | Material testing, creating new alloys/ceramics | Precise temperature control for R&D experiments |

Ready to enhance your lab's capabilities with a reliable muffle furnace? KINTEK specializes in high-performance lab equipment, including muffle furnaces designed for precise ashing, heat treatment, and material testing. Our solutions ensure contamination-free results for laboratories in research, quality control, and materials science. Contact our experts today to find the perfect furnace for your specific application and achieve superior, repeatable results.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the primary function of a laboratory oven in coal fly ash zeolite production? Achieve Optimal Activation

- What are the key applications of a muffle furnace in cement fire research? Ensure Precision in Thermal Testing

- What are 2 uses of oven in the laboratory? Essential for Sterilization and Drying

- Why is a high-temperature muffle furnace required for the sintering of lithium-based tritium breeding ceramics? Optimize Density

- What is the function of an annealing furnace in Na3PS4 synthesis? Achieve High-Conductivity Cubic-Phase Electrolytes

- What role do muffle or tube furnaces play in ceramic monolith calcination? Optimize Catalyst Support Performance

- What is ashing in chemistry? Enhance Analytical Accuracy with Ashing Techniques

- What is the purpose of using a high-temperature muffle furnace for copper foil modification? Enhance Battery Stability