In short, Plasma-Assisted Physical Vapor Deposition (PA-PVD) is an advanced coating process that enhances traditional Physical Vapor Deposition (PVD) by using plasma to ionize the coating material. This ionization gives the vaporized atoms more energy, resulting in thin films that are denser, more adherent, and have superior properties compared to those created by standard PVD.

The critical difference is simple: standard PVD relies on neutral atoms passively condensing onto a surface. PA-PVD actively energizes these atoms by turning them into ions within a plasma, allowing for a much more controlled and forceful deposition that dramatically improves the final coating's quality.

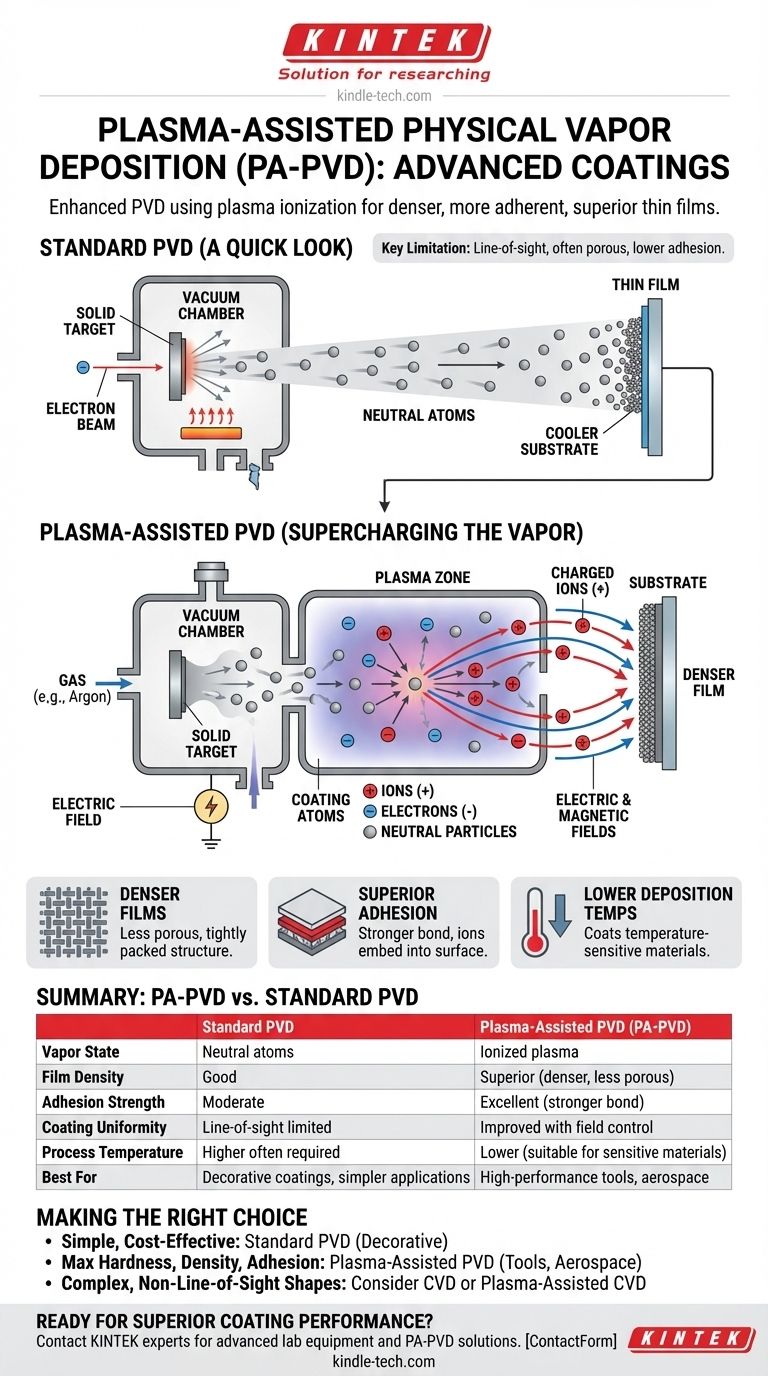

First, A Quick Look at Standard PVD

The Core Mechanism: From Solid to Vapor

Physical Vapor Deposition is a vacuum-based process. Inside a chamber, a high-energy source—like an electron beam or electric arc—vaporizes a solid source material, known as the "target."

These vaporized atoms travel through the vacuum and condense onto a cooler substrate (the object being coated), forming a thin, solid film.

The Key Limitation

In its most basic form, PVD is a "line-of-sight" process. The neutral vapor atoms travel in a relatively straight line from the source to the substrate.

This can make it difficult to uniformly coat complex shapes and can result in coatings with lower density or adhesion under certain conditions.

The Role of Plasma: Supercharging the Vapor

What is Plasma in this Context?

Plasma is often called the fourth state of matter. For PA-PVD, it is created by introducing a gas (like argon) into the vacuum chamber and energizing it with an electric field.

This process strips electrons from the gas atoms, creating a highly energetic environment filled with charged ions, electrons, and neutral particles.

The Power of Ionization

When the vaporized coating material passes through this plasma, it collides with these energetic particles. These collisions transfer energy and knock electrons off the coating atoms, turning them into positively charged ions.

A key example of this is Arc Vapor Deposition, a type of PA-PVD where a high percentage of the vaporized material becomes ionized.

Benefits of an Ionized Vapor Stream

Creating an ionized vapor stream fundamentally changes the deposition process. Because the coating atoms are now charged, they can be manipulated by electric and magnetic fields.

This allows us to accelerate them toward the substrate with high energy. This energetic bombardment results in several key advantages:

- Denser Films: The high energy of the arriving ions helps to form a more tightly packed, less porous film structure.

- Superior Adhesion: Ions can embed themselves slightly into the substrate's surface, creating a much stronger bond between the coating and the part.

- Lower Deposition Temperatures: The energy required for a high-quality film comes from the plasma and ion acceleration, not just from heating the substrate. This makes it possible to coat temperature-sensitive materials.

Understanding the Trade-offs and Alternatives

PA-PVD vs. Standard PVD

Standard PVD is simpler and often more cost-effective. It is perfectly suitable for many applications, such as applying optical films or decorative coatings.

PA-PVD is chosen when the performance of the coating is critical. The added complexity of generating and controlling the plasma is justified by the need for exceptionally hard, dense, or corrosion-resistant films for tools or aerospace components.

A Note on Plasma-Assisted CVD (PACVD)

A related but distinct process is Plasma-Assisted Chemical Vapor Deposition (PACVD). While PVD starts with a solid target, CVD uses precursor gases that react to form the film.

Plasma serves a similar function in both: it provides the activation energy to drive the process at lower temperatures. However, the source material (solid vs. gas) is the key differentiator.

Making the Right Choice for Your Goal

- If your primary focus is a simple, cost-effective coating: Standard PVD methods are often the most direct and economical solution.

- If your primary focus is maximum hardness, density, and adhesion: Plasma-Assisted PVD is necessary for creating high-performance coatings for demanding applications like cutting tools or engine parts.

- If your primary focus is coating complex, non-line-of-sight shapes: You may need to evaluate Chemical Vapor Deposition (CVD) or its plasma-assisted variants, which excel at uniform coverage.

Ultimately, integrating plasma into the PVD process is a strategic choice to transform a simple condensation into a highly controlled, energetic film growth for superior material performance.

Summary Table:

| Feature | Standard PVD | Plasma-Assisted PVD (PA-PVD) |

|---|---|---|

| Vapor State | Neutral atoms | Ionized plasma |

| Film Density | Good | Superior (denser, less porous) |

| Adhesion Strength | Moderate | Excellent (stronger bond) |

| Coating Uniformity | Line-of-sight limited | Improved with field control |

| Process Temperature | Higher often required | Lower (suitable for sensitive materials) |

| Best For | Decorative coatings, simpler applications | High-performance tools, aerospace components |

Ready to achieve superior coating performance for your laboratory applications? At KINTEK, we specialize in advanced lab equipment, including Plasma-Assisted PVD solutions that deliver denser, more adherent thin films for demanding applications. Our expertise ensures you get the right coating technology for cutting tools, aerospace components, and other high-performance needs. Contact our experts today to discuss how PA-PVD can enhance your lab's capabilities and material performance!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings