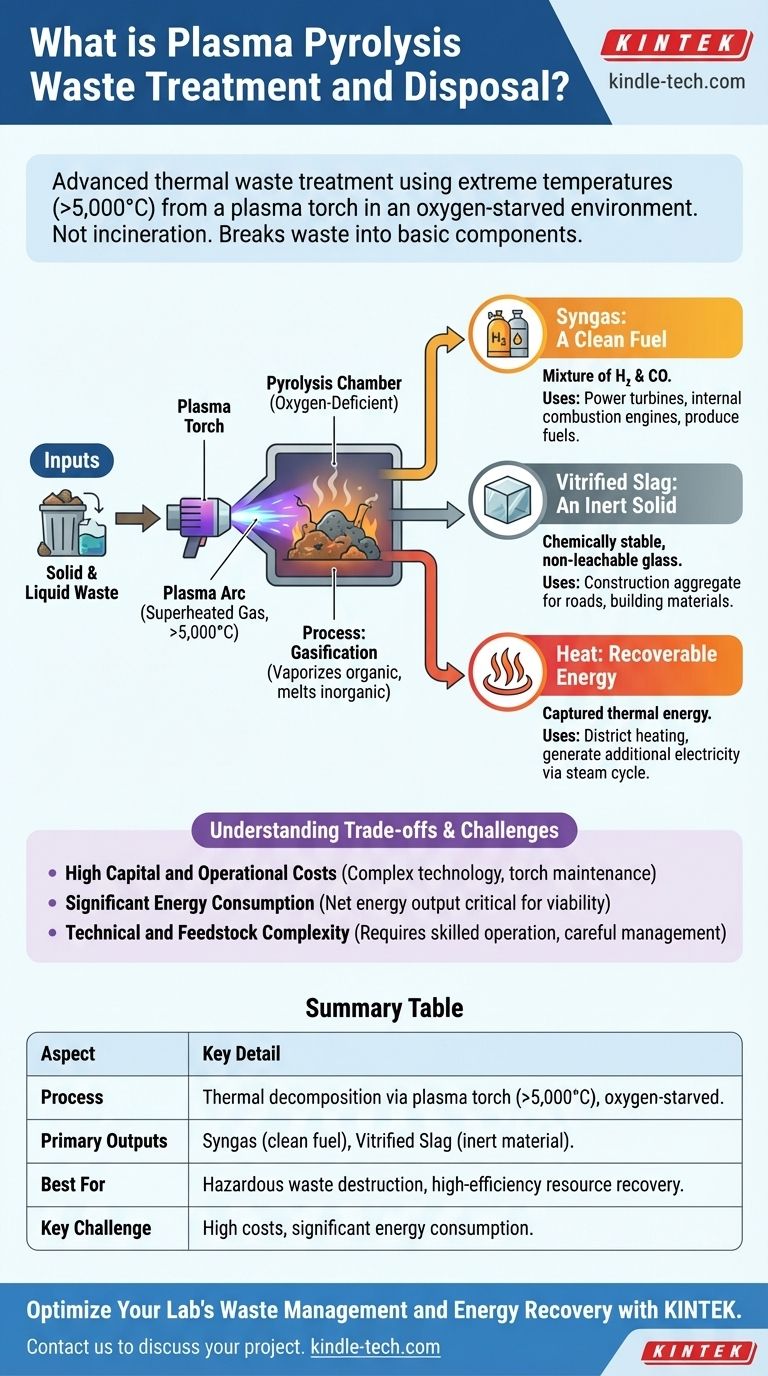

In short, plasma pyrolysis is an advanced thermal waste treatment process that uses extremely high temperatures generated by a plasma torch—often exceeding 5,000°C—to break down waste into its basic elemental components. It is not incineration; it occurs in an oxygen-starved environment, which prevents combustion and the formation of many toxic byproducts. The process converts solid and liquid waste into a valuable fuel gas and an inert, glass-like solid.

Plasma pyrolysis represents one of the most complete and powerful methods for waste destruction, capable of turning hazardous materials into useful energy and inert byproducts. However, its significant energy requirements and high operational costs are critical factors that currently limit its widespread use for general municipal waste.

How Plasma Pyrolysis Fundamentally Works

To understand this technology, it's essential to break down its two core components: the plasma that provides the energy and the pyrolysis that transforms the waste.

The Role of Plasma

Plasma is often called the "fourth state of matter" after solid, liquid, and gas. You can think of it as a superheated, electrically charged gas, similar to what's found in lightning or the sun.

In this process, a plasma torch passes a high-voltage electric current through a gas (like air or argon), stripping electrons from the atoms and creating an intensely hot plasma arc. This arc acts as a clean, powerful heat source.

The Pyrolysis Process

Pyrolysis is the thermal decomposition of materials at elevated temperatures in an oxygen-deficient environment. Unlike incineration, which burns waste with oxygen, pyrolysis breaks down complex molecules into simpler ones.

When waste is introduced into the plasma-heated chamber, the intense heat instantly vaporizes the organic materials and melts the inorganic ones, initiating a process called gasification.

The Outputs: Turning Waste into Resources

The primary goal of plasma pyrolysis is not just to destroy waste but to convert it into valuable, usable products.

Syngas: A Clean Fuel

The main output is a synthetic gas, or syngas. This is a mixture of primarily hydrogen (H₂) and carbon monoxide (CO).

This syngas is a valuable fuel. It can be cleaned and then used to power turbines or internal combustion engines to generate electricity, or it can be used as a chemical feedstock to produce fuels like ethanol and methanol.

Vitrified Slag: An Inert Solid

All the inorganic materials in the waste stream—such as glass, metals, and soil—melt down under the extreme heat. Upon cooling, they form a hard, glass-like substance called vitrified slag.

This slag is chemically stable and non-leachable, meaning hazardous elements are permanently trapped within its structure. It is safe to handle and can be used as a durable construction aggregate for roads or building materials.

Heat: Recoverable Energy

The process generates an enormous amount of heat. This thermal energy can be captured and used for district heating or to generate additional electricity through a steam cycle, improving the overall energy efficiency of the plant.

Understanding the Trade-offs and Challenges

While powerful, plasma pyrolysis is not a universal solution. Its implementation requires a clear understanding of its significant trade-offs.

High Capital and Operational Costs

Plasma gasification plants are technologically complex and expensive to build. Plasma torches themselves are sophisticated pieces of equipment that require specialized maintenance and have a finite operational life.

Significant Energy Consumption

Generating and sustaining plasma is an energy-intensive process. A plant's net energy output—the energy it produces minus the energy it consumes—is a critical metric. For waste streams with low energy value, the plant might consume more electricity than it generates, making it economically unviable.

Technical and Feedstock Complexity

The system requires highly skilled personnel to operate and maintain. Furthermore, the composition and moisture content of the waste feedstock must be carefully managed to ensure stable and efficient operation of the gasifier.

Making the Right Choice for Your Goal

Plasma pyrolysis is a specialized tool, best deployed where its unique advantages outweigh its costs.

- If your primary focus is destroying hazardous waste: This technology is an excellent choice for things like medical waste, asbestos, or chemical sludge, as it ensures complete destruction and renders the byproducts inert.

- If your primary focus is large-scale municipal solid waste (MSW) disposal: The high cost and energy input often make plasma pyrolysis less competitive than more established waste-to-energy incineration or advanced recycling and composting programs.

- If your primary focus is maximizing resource recovery: Plasma pyrolysis offers a high potential for converting waste into clean energy and materials, but the net energy balance must be carefully analyzed to ensure the project is sustainable.

Ultimately, plasma pyrolysis offers a compelling vision for the future of waste management, providing a path to near-total material destruction and resource conversion.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Thermal decomposition using a plasma torch (>5,000°C) in an oxygen-starved environment. |

| Primary Outputs | Syngas (H₂, CO - a clean fuel) and vitrified slag (inert, glass-like construction material). |

| Best For | Destruction of hazardous waste (medical, chemical) and high-efficiency resource recovery. |

| Key Challenge | High capital/operational costs and significant energy consumption. |

Optimize Your Lab's Waste Management and Energy Recovery with KINTEK

Are you dealing with hazardous lab waste or seeking advanced methods for resource recovery? Plasma pyrolysis technology offers a path to complete destruction and valuable energy conversion. KINTEK specializes in providing robust lab equipment and expert solutions tailored to complex laboratory needs.

Let our experts help you evaluate if this advanced technology is the right fit for your specific goals. Contact us today to discuss your project and discover how KINTEK can support your innovation in waste treatment and energy efficiency.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method