In the world of modern jewelry, Physical Vapor Deposition (PVD) is a high-tech coating process used to apply a durable, decorative finish to a base metal like stainless steel. Unlike traditional plating, PVD uses a vacuum chamber to molecularly bond a thin layer of metal onto the jewelry's surface. This results in a finish that is significantly more resilient and long-lasting than conventional methods.

PVD coating is not merely a surface layer; it's an advanced finishing process that transforms stainless steel jewelry, making it exceptionally resistant to scratches, corrosion, and fading while offering a vast spectrum of vibrant colors.

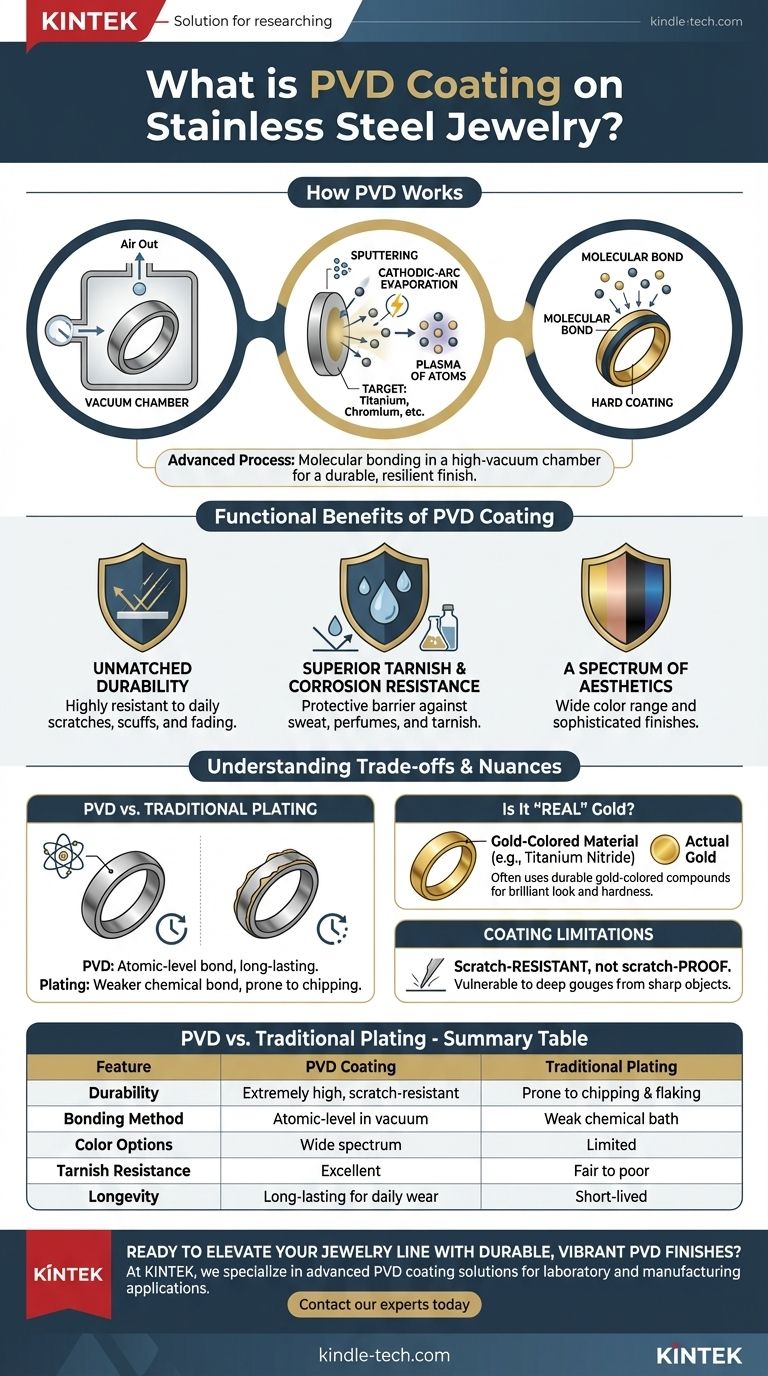

How Does the PVD Process Work?

PVD is a clean, dry, vacuum-based process that stands in stark contrast to the wet chemical baths of traditional electroplating. The technique involves several sophisticated steps to create a superior bond.

The Vacuum Chamber Environment

First, the stainless steel jewelry is placed inside a sealed, high-vacuum chamber. All the air is pumped out to create a pristine environment, which is crucial for ensuring the coating adheres perfectly without contaminants.

From Solid Material to Vapor

A target material—such as titanium, chromium, or even real gold particles—is vaporized into a plasma of atoms. This is typically achieved through advanced methods like sputtering (bombarding the target with ions) or cathodic-arc evaporation (using a high-current arc to vaporize the material).

Atomic Bonding to the Steel

This vaporized metal is then precisely deposited onto the stainless steel jewelry, item by item. It doesn't just sit on top; it forms a strong atomic bond with the steel's surface, creating a dense, hard, and chemically inert layer.

The Functional Benefits of PVD Coating

The "why" behind PVD's popularity lies in its functional superiority. It's chosen when both aesthetics and performance are critical.

Unmatched Durability

The molecular bond created during the PVD process makes the coating incredibly durable. PVD-finished jewelry is highly resistant to the scratches, scuffs, and fading that occur with daily wear, far outperforming traditional plating.

Superior Tarnish and Corrosion Resistance

While stainless steel is already corrosion-resistant, the PVD coating adds a protective barrier. This layer shields the jewelry from sweat, perfumes, and lotions, preventing the tarnish and discoloration that can affect lesser-quality finishes.

A Spectrum of Aesthetic Possibilities

PVD unlocks a wide range of color options that go far beyond standard metals. It can produce rich golds, rose golds, deep blacks, blues, and even iridescent rainbow effects. It also allows for different surface textures, from a highly polished shine to a sophisticated matte finish.

Understanding the Trade-offs and Nuances

While PVD is an excellent technology, it's important to understand its context and limitations to make an informed choice.

PVD vs. Traditional Electroplating

The most common alternative, electroplating, submerges jewelry in a chemical solution and uses an electric current to deposit a thin layer of metal. This layer is softer and has a weaker bond, making it prone to chipping, flaking, and wearing off quickly. PVD is a more significant investment but provides far greater longevity.

Is It "Real" Gold?

Gold PVD coatings can be made with actual gold, but often a gold-colored material like Titanium Nitride is used. This compound provides the brilliant look of gold but is significantly harder and more durable, making it an ideal choice for high-contact items. Both approaches enhance the jewelry's durability.

The Limits of the Coating

PVD coating is scratch-resistant, not scratch-proof. While it can easily withstand daily bumps and scrapes, a deep gouge from a sharp or abrasive object can still penetrate the coating and expose the stainless steel underneath. However, for everyday use, its resilience is exceptional.

Making the Right Choice for Your Jewelry

Choosing PVD-coated stainless steel depends on balancing your priorities for aesthetics, longevity, and use case.

- If your primary focus is longevity for daily wear: PVD is the superior choice for jewelry that must resist scratches and tarnish from constant use.

- If your primary focus is vibrant, non-traditional color: PVD offers a durable palette of options like black, blue, and coffee that are difficult to achieve with other long-lasting methods.

- If your primary focus is the look of gold without the fragility: PVD-coated stainless steel provides a durable, long-lasting gold-tone finish that is far more resilient than traditional gold plating.

Ultimately, opting for PVD-coated stainless steel means choosing modern engineering for jewelry that is built to look brilliant and last.

Summary Table:

| Feature | PVD Coating | Traditional Plating |

|---|---|---|

| Durability | Extremely high, scratch-resistant | Prone to chipping and flaking |

| Bonding Method | Atomic-level bond in a vacuum | Weak bond via chemical bath |

| Color Options | Wide spectrum (black, gold, blue, etc.) | Limited |

| Tarnish Resistance | Excellent | Fair to poor |

| Longevity | Long-lasting for daily wear | Short-lived |

Ready to elevate your jewelry line with durable, vibrant PVD finishes? At KINTEK, we specialize in advanced PVD coating solutions for laboratory and manufacturing applications. Our expertise ensures your stainless steel jewelry achieves a superior, long-lasting finish that resists scratches and tarnish. Contact our experts today to discuss how we can support your production needs with reliable, high-performance coating technology.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is plasma in CVD process? Lowering Deposition Temperatures for Heat-Sensitive Materials

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is meant by vapor deposition? A Guide to Atomic-Level Coating Technology

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films