In a rotary kiln, the refractory is a critical, heat-resistant lining installed inside the main steel shell. Its primary purpose is to insulate the structural shell from the extreme internal processing temperatures, prevent heat loss to the environment, and resist chemical and physical wear from the material being processed.

Refractory is more than just insulation; it is an engineered system that dictates the kiln's structural integrity, thermal efficiency, and operational lifespan. The selection of the right refractory is a careful balance of thermal performance, chemical resistance, and mechanical durability.

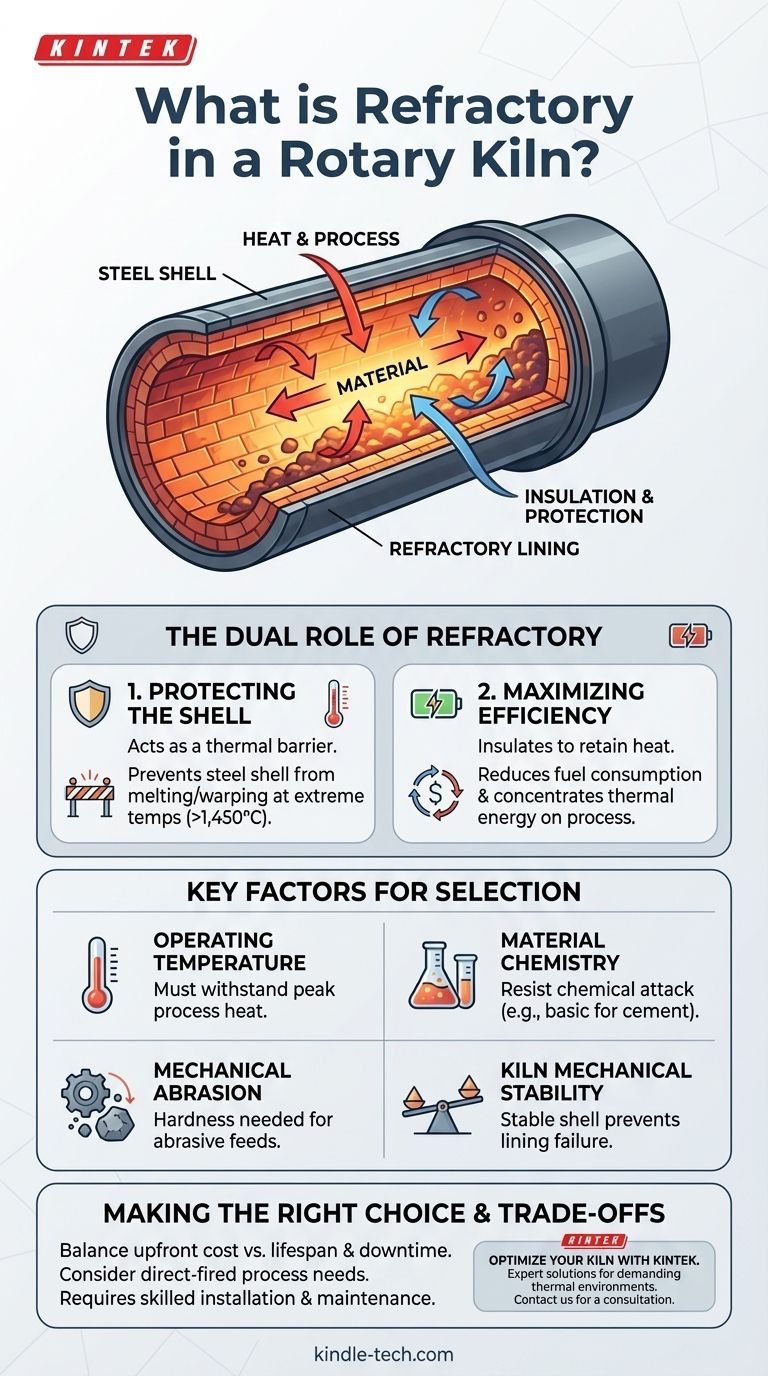

The Dual Role of Refractory Lining

The refractory lining serves two fundamental purposes that are essential for the kiln's function and longevity. It is not an optional component in direct-fired kilns but a core part of the design.

Protecting the Kiln Shell

The primary function is protection. The steel shell of a rotary kiln provides the mechanical structure but would quickly fail, warp, or melt if directly exposed to typical operating temperatures, which can exceed 1,450°C (2,640°F).

The refractory lining acts as a thermal barrier, keeping the shell's temperature within safe mechanical limits. This is crucial for maintaining the structural integrity of the entire kiln assembly as it rotates.

Maximizing Thermal Efficiency

The second function is insulation. By minimizing the amount of heat that escapes through the kiln shell, the refractory lining ensures that the thermal energy is concentrated on the material being processed.

This retention of heat is vital for reducing fuel consumption and ensuring the desired chemical reactions or physical changes occur efficiently within the material.

Key Factors Influencing Refractory Selection

Choosing a refractory is not a one-size-fits-all decision. It is a highly specific engineering choice based on the unique conditions of each kiln's application.

Operating Temperature

The maximum temperature of the process is the first consideration. Refractories are rated for different service temperatures, and selecting one that can withstand the kiln's peak heat is non-negotiable.

Material Chemistry

The material being processed dictates the required chemical resistance. For example, the alkaline environment in a cement kiln requires basic refractories like magnesite bricks to prevent chemical attack.

Conversely, a process like iron ore reduction might use low-iron alumina bricks that are more suited to that specific chemical environment.

Mechanical Abrasion

As the kiln rotates, the material inside tumbles and grinds against the lining. The abrasiveness of the raw material determines the required mechanical strength and hardness of the refractory. A harder, more durable refractory is needed for highly abrasive feeds.

Mechanical Stability of the Kiln

The service life of the refractory is directly tied to the mechanical condition of the kiln shell. A shell that flexes, vibrates, or is distorted will transfer stress to the refractory lining, causing bricks to crack and fail prematurely.

Understanding the Trade-offs and Limitations

While essential, the refractory system comes with inherent complexities and trade-offs that must be managed.

The Cost vs. Lifespan Balance

High-performance refractories that offer superior heat resistance and durability come at a significant cost. Operators must balance the upfront investment against the risk of more frequent downtime and replacement costs associated with lower-grade materials.

The Direct-Fired vs. Indirect-Fired Distinction

Refractory lining is a defining feature of direct-fired kilns, where the flame and hot gases are in direct contact with the material.

In indirect-fired kilns, where the shell is heated from the outside, adding an internal refractory lining would be counterproductive. It would act as an insulator, preventing heat from reaching the material and severely reducing the kiln's efficiency.

Installation and Maintenance

Refractory linings are not permanent. They require skilled installation to ensure tight-fitting joints and proper expansion gaps. Over time, they wear down and require periodic inspection and replacement, which is a major maintenance event for any plant.

Making the Right Choice for Your Process

Your choice of refractory should be driven by the specific demands of your operation.

- If your primary focus is processing highly abrasive materials: Prioritize a refractory with high mechanical strength and hardness.

- If your primary focus is operating at extreme temperatures: Select a refractory with a thermal rating that comfortably exceeds your peak process temperature.

- If your primary focus is processing chemically reactive materials (like cement): Choose a refractory with a chemical composition specifically designed to resist attack from your process materials.

- If your primary focus is maximizing operational uptime: Invest in premium refractory materials and ensure the kiln's mechanical stability is properly maintained to extend lining life.

Ultimately, treating the refractory lining as an integral and dynamic part of the kiln system is the key to safe, efficient, and profitable operation.

Summary Table:

| Factor | Impact on Refractory Selection |

|---|---|

| Operating Temperature | Dictates the required heat resistance and thermal rating of the material. |

| Material Chemistry | Determines the chemical composition needed to resist corrosion (e.g., basic bricks for cement). |

| Mechanical Abrasion | Influences the choice of hardness and strength to withstand tumbling materials. |

| Kiln Mechanical Stability | A stable shell is critical for preventing premature refractory failure from stress and vibration. |

Optimize your rotary kiln's performance and longevity with the right refractory solution. The correct lining is critical for protecting your investment, maximizing thermal efficiency, and minimizing downtime. At KINTEK, we specialize in high-performance lab equipment and consumables, including solutions for demanding thermal processing environments. Let our experts help you select the ideal refractory for your specific application and operational goals. Contact KINTALK today for a consultation to ensure your kiln operates at peak efficiency.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

People Also Ask

- How is slow pyrolysis done? A Step-by-Step Guide to Efficient Biochar Production

- What are the advantages of pyrolysis over gasification? Maximize Product Value and Energy Storage

- How does the process of pyrolysis work? Unlock the Power of Chemical Recycling and Energy Recovery

- How is pyrolysis sustainable? Turning Waste into Energy and Circular Materials

- Is pyrolysis environmentally friendly? Unlocking Sustainable Waste-to-Energy Solutions

- What is the difference between incineration pyrolysis and gasification? Mastering Thermal Conversion Technologies

- What are the advantages of pyrolysis system? Turn Waste into Renewable Energy & Revenue

- What is the effect of torrefaction on fast pyrolysis bio-oil? Achieve Higher Quality, More Stable Bio-Fuel