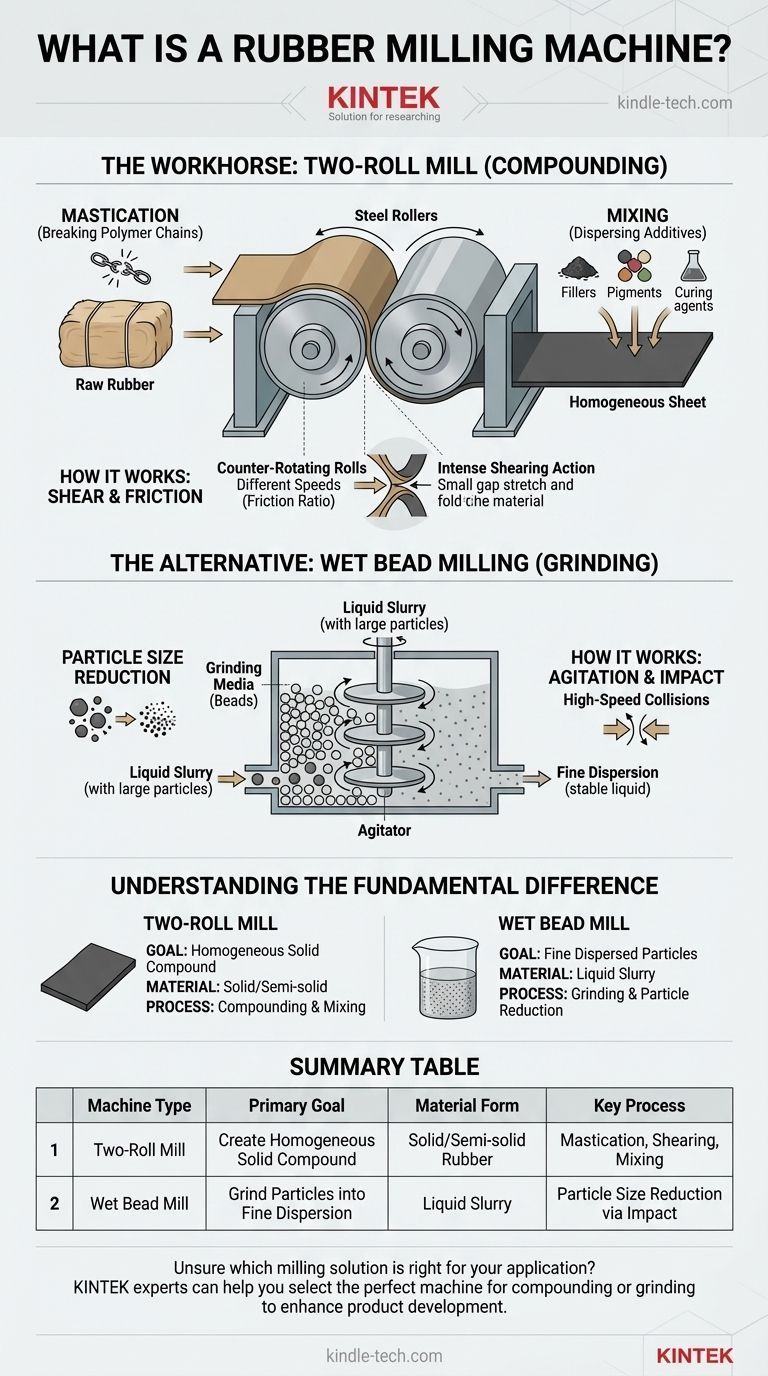

At its core, a rubber milling machine is a device used to process raw rubber into a usable compound by mechanically working it and mixing it with various additives. The most common type is the two-roll mill, which uses two large, counter-rotating steel rollers to knead, shear, and blend the material into a homogeneous, plastic-like sheet.

While the term "rubber milling" can be broad, it most often refers to the process of compounding solid rubber on a two-roll mill. This should not be confused with other milling types, like bead milling, which are used for a different purpose: grinding fine particles within a liquid.

The Workhorse of Rubber Compounding: The Two-Roll Mill

The two-roll mill is a foundational piece of equipment in the rubber industry. Its primary function is to transform tough, elastic natural or synthetic rubber into a pliable compound that can be shaped and vulcanized.

Core Function: Mastication and Mixing

The process begins with mastication, where the intense mechanical force of the rollers breaks down the long polymer chains of the raw rubber. This reduces its elasticity and makes it softer and more receptive to additives.

Following mastication, ingredients are added directly into the mill. The rolling action serves to mix and disperse these additives—such as fillers, pigments, and curing agents—uniformly throughout the rubber mass.

How It Works: Shear and Friction

A two-roll mill consists of two large, horizontal steel rolls positioned closely together. These rolls rotate towards each other at slightly different speeds.

This speed differential, known as the friction ratio, is critical. It creates an intense shearing action in the small gap (or "nip") between the rolls, which pulls, stretches, and folds the rubber, ensuring thorough mixing and heating.

An Alternative Process: Wet Bead Milling

While not typically what is meant by a "rubber mill" in the context of compounding, bead milling is another milling technology sometimes used in the broader polymer industry. Its purpose is entirely different.

Core Function: Particle Size Reduction

The goal of a bead mill is not to mix a large, solid mass, but to grind solid particles down to a very fine size within a liquid medium. The output is a stable liquid dispersion or slurry.

How It Works: Agitation and Impact

A bead mill consists of a chamber filled with small grinding media, such as ceramic or glass beads. An agitator moves these beads at high speed, causing them to collide with each other and with the material being processed.

These repeated, high-energy impacts shatter solid particles and break down agglomerates, resulting in a fine, uniform particle size.

Understanding the Fundamental Difference: Compounding vs. Grinding

Confusing these two processes is a common pitfall. The distinction lies in their primary goal and the state of the material being processed.

Goal: Homogeneous Mixture vs. Fine Particles

A two-roll mill aims to create a homogeneous solid compound. Its job is to blend different ingredients into a single, workable mass.

A bead mill aims to create fine, dispersed particles within a liquid. Its job is to reduce particle size, not to blend a solid mass.

Material Form: Solid Mass vs. Liquid Slurry

The two-roll mill works with high-viscosity, solid or semi-solid materials, transforming a tough bale of rubber into a pliable sheet.

The bead mill works with a low-viscosity liquid slurry, a mixture of solid particles suspended in a liquid carrier.

Application in Rubber

The two-roll mill is for primary compounding. In contrast, a bead mill might be used in a secondary process, such as preparing a liquid colorant to be added to latex or grinding recycled rubber powder into a fine filler.

Making the Right Choice for Your Goal

Understanding the objective is key to identifying the correct machine for the task.

- If your primary focus is to mix raw rubber with additives to create a solid compound for molding or extrusion: The two-roll mill is the standard industrial machine for this purpose.

- If your primary focus is to grind down solid particles (like pigments or fillers) within a liquid to create a fine dispersion: A wet bead mill is the appropriate technology.

Ultimately, each machine is a specialized tool designed to solve a very different engineering problem.

Summary Table:

| Machine Type | Primary Goal | Material Form | Key Process |

|---|---|---|---|

| Two-Roll Mill | Create a homogeneous solid compound | Solid/Semi-solid rubber | Mastication, shearing, and mixing |

| Wet Bead Mill | Grind particles into a fine dispersion | Liquid slurry | Particle size reduction via impact |

Unsure which milling solution is right for your rubber or polymer application? KINTEK specializes in lab equipment and consumables for all your processing needs. Our experts can help you select the perfect machine—whether for compounding or grinding—to enhance your product development and quality control. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Powerful Plastic Crusher Machine

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

People Also Ask

- What are the three 3 basic types of mixers? Find Your Perfect Match for Baking & Production

- What is the purpose of a vulcanizing machine? Transform Rubber into High-Performance Parts

- What products can be made with injection molding? The Engine of Mass Production

- What is the process of extrusion blowing? A Guide to Efficient Hollow Plastic Part Production

- What is the process of calendering? A Guide to High-Volume Plastic Film Production

- What is a laboratory mixer used for? Choose the Right Tool for Liquids or Solids

- What is the use of two roll mill? Essential for Polymer Mixing, R&D, and Quality Control

- What is the manufacturing process of rubber molding? Injection, Compression, or Transfer Molding?