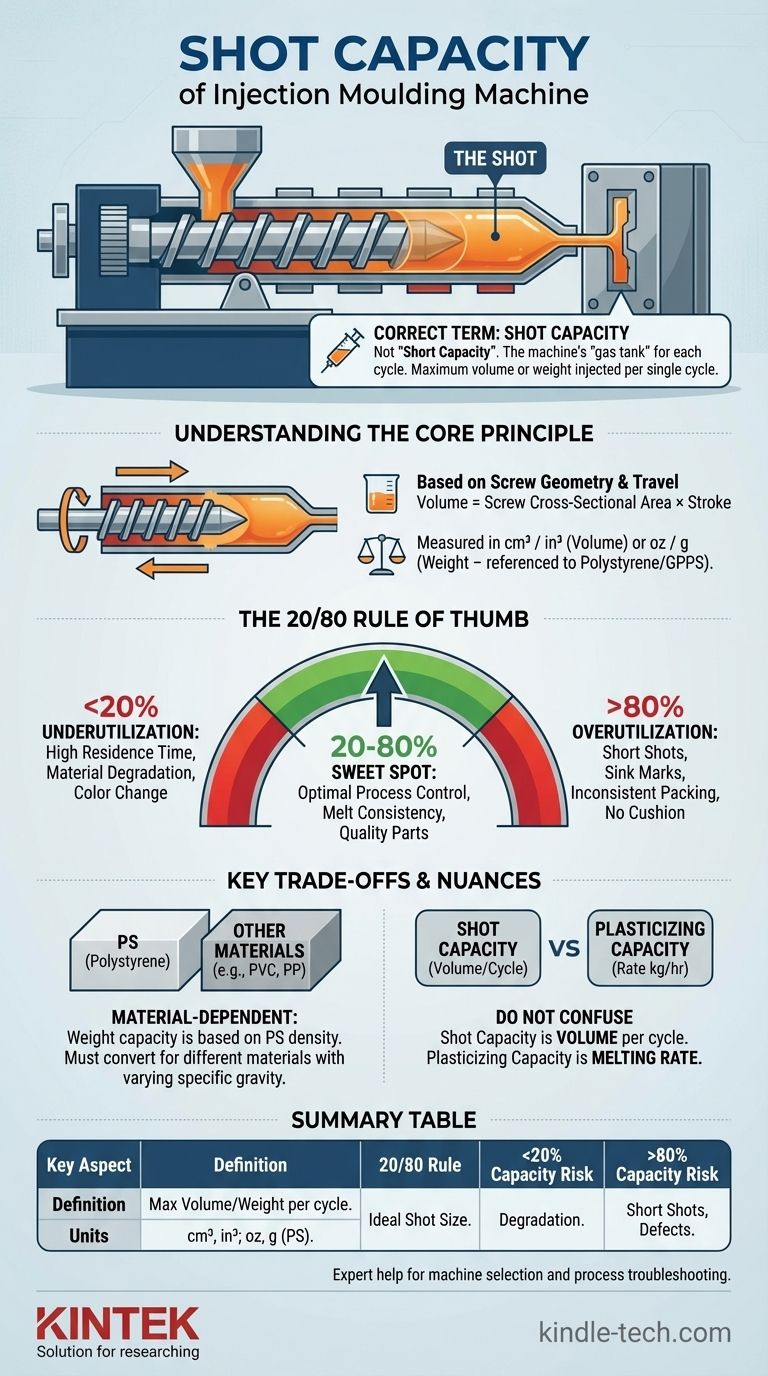

While the term is often heard as "short capacity," the correct technical term in injection molding is shot capacity, also known as injection capacity. It refers to the maximum volume or weight of molten plastic that a machine's screw can push forward and inject into a mold during a single cycle. This is one of the most fundamental specifications of an injection molding machine.

Shot capacity is the machine's "gas tank" for each cycle. Understanding this limit is not just about knowing if a machine can make a part, but whether it can make it well, without defects and with a stable, repeatable process.

Understanding Shot Capacity: The Core Principle

Shot capacity is a primary design parameter of an injection molding machine, dictating the maximum size of the parts it can produce.

What is Shot Capacity?

Shot capacity is the maximum volume of melt the screw can displace as it moves forward during injection. It is a hard limit determined by the machine's physical construction.

This specification is always listed by the manufacturer and is a key factor in matching a machine to a specific job.

How is it Measured?

Shot capacity is measured in two common ways:

- Volume: Typically expressed in cubic centimeters (cm³) or cubic inches (in³).

- Weight: Often expressed in ounces (oz) or grams (g).

Crucially, when expressed as weight, it is always referenced to a specific material, most commonly General Purpose Polystyrene (GPPS). This is a critical detail for accurate calculations.

The Role of the Screw and Barrel

The capacity is a direct function of the screw's geometry within the barrel. It is calculated by multiplying the cross-sectional area of the screw by its maximum possible travel distance (the screw stroke).

When the screw rotates and retracts to melt new plastic, it creates a "shot" of molten material in the space in front of its tip. The machine's shot capacity is the largest possible volume this space can hold.

Why Shot Capacity is Critical for Production

A mismatch between the required shot size and the machine's capacity is a primary source of molding defects and process instability.

Matching the Machine to the Mold

The most important application of shot capacity is ensuring the machine can physically fill the mold. The machine's shot capacity must be larger than the total volume of the part(s) plus the volume of the runner system that delivers the plastic.

If the required volume exceeds the machine's capacity, the result will be a "short shot"—an incomplete part.

The 20/80 Rule of Thumb

For optimal processing, the total shot weight for your part should use between 20% and 80% of the machine's rated shot capacity.

This range is considered the "sweet spot" for process control, melt consistency, and part quality.

Consequences of a Mismatch

Operating outside the 20/80 rule can lead to significant problems.

Using less than 20% of the capacity means the plastic sits in the hot barrel for too long. This extended residence time can cause material degradation, color changes, and poor mechanical properties.

Using more than 80% of the capacity leaves little to no "cushion" of material for the packing and holding phase. This leads to inconsistent part weight, sink marks, poor dimensional control, and a stressful, non-robust process.

Understanding the Trade-offs and Nuances

Simply looking at the manufacturer's spec sheet is not enough. You must consider the specific material and process requirements.

It is Always Material-Dependent

A machine's shot capacity stated in ounces or grams is based on polystyrene (PS). If you are using a different material with a different melt density, you must adjust your calculations.

For example, a machine rated for 8 oz of PS will inject a heavier weight of dense PVC but a lighter weight of less-dense Polypropylene (PP). You must convert the volume based on the specific gravity of your chosen material.

Shot Capacity vs. Plasticizing Capacity

Do not confuse shot capacity with plasticizing capacity.

- Shot Capacity: The volume of plastic injected per cycle.

- Plasticizing Capacity: The rate at which the machine can melt raw plastic, measured in kg/hr or lb/hr.

For parts with very fast cycle times, your machine's ability to melt plastic fast enough (plasticizing rate) can become the bottleneck, even if the shot capacity is adequate.

Selecting the Right Machine for Your Part

Use your understanding of shot capacity to make deliberate, data-driven decisions that prevent production problems before they start.

- If your primary focus is designing a new part: Calculate your total required shot volume (part + runner) and ensure it falls comfortably within the 20% to 80% utilization range of your target machine.

- If your primary focus is troubleshooting defects: Verify that your current shot size is not too close to the machine's minimum or maximum capacity, as this is a common root cause of degradation and inconsistent filling.

- If your primary focus is changing materials: Always convert the machine's rated shot capacity (based on PS) to the equivalent weight for your specific material by using its melt density.

Mastering the concept of shot capacity is a fundamental step toward achieving a stable, repeatable, and profitable injection molding process.

Summary Table:

| Key Aspect | Description |

|---|---|

| Definition | Maximum volume/weight of plastic a machine can inject in one cycle. |

| Common Units | cm³, in³ (volume); oz, g (weight, referenced to Polystyrene). |

| The 20/80 Rule | Ideal shot size is 20-80% of machine capacity for optimal quality. |

| < 20% Capacity | Risk of material degradation from long residence time. |

| > 80% Capacity | Risk of short shots, sink marks, and inconsistent packing. |

Struggling with short shots or material degradation? Your injection molding machine's shot capacity could be the culprit.

At KINTEK, we specialize in providing the right lab and production equipment to meet your specific needs. Whether you're designing a new part, troubleshooting defects, or changing materials, having the correct injection molding machine is paramount to your success.

Let our experts help you:

- Select the perfect machine with the ideal shot capacity for your application.

- Troubleshoot process issues related to shot size and material behavior.

- Ensure a stable, repeatable process that maximizes part quality and profitability.

Don't let an improperly sized machine limit your production. Contact KINTEL today for a consultation and ensure your next project is a resounding success!

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- Anti-Cracking Press Mold for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Test Sieves and Sieving Machines

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- What is the application of injection moulding machine? Powering Mass Production for Complex Parts

- What is a positive of injection moulding? Achieve High-Volume Production with Unmatched Efficiency

- What is molding technique? A Guide to High-Volume, Complex Part Manufacturing

- What is the difference between injection molding and pressure molding? A Guide to Choosing the Right Process

- What is the injection molding process? A Guide to High-Volume Part Production