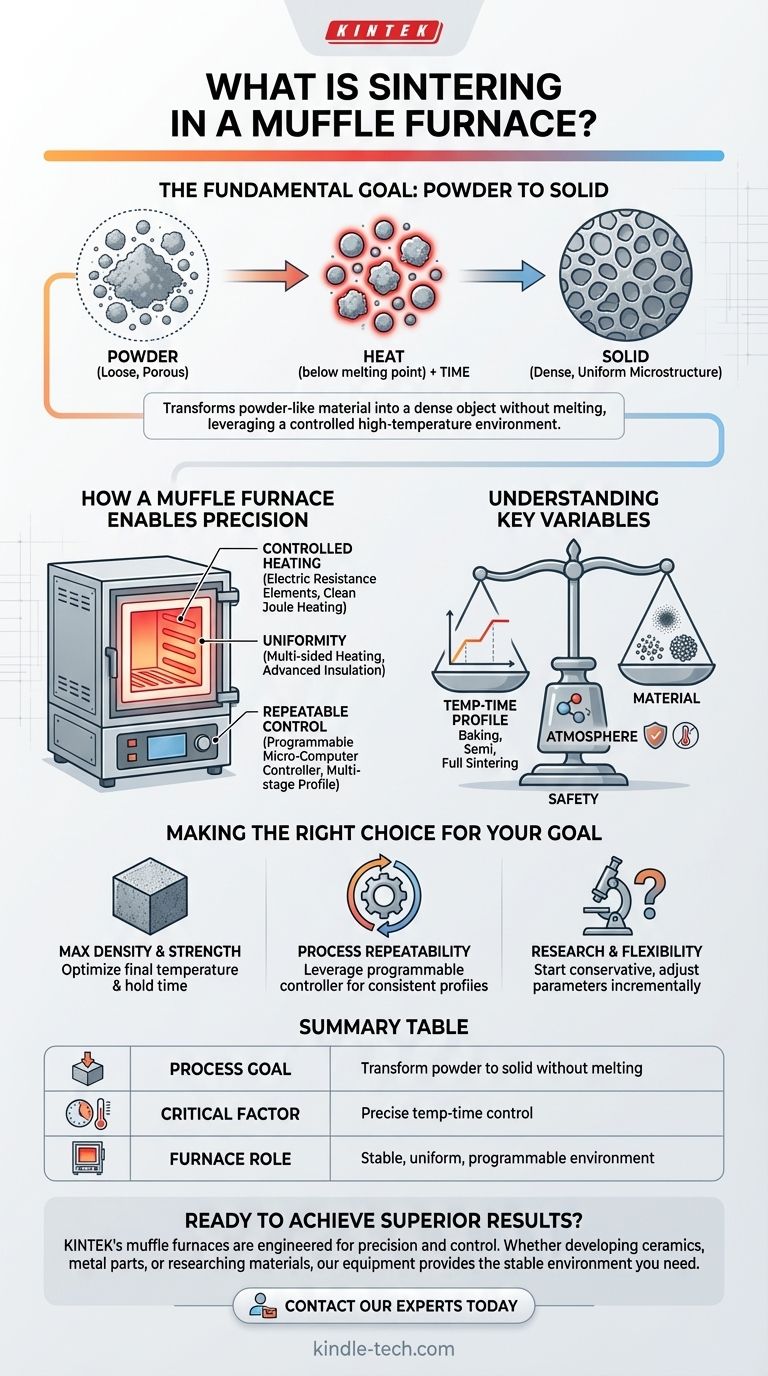

At its core, sintering is a thermal process that transforms a powder-like or loosely packed material into a solid, dense object without melting it. Using a muffle furnace for this process means leveraging its exceptionally stable and precisely controlled high-temperature environment to achieve this transformation. The furnace acts as the precision instrument, providing the controlled energy needed for the material’s particles to bond and fuse together.

The critical insight is that a muffle furnace is not just an oven; it is a precision tool. Successful sintering depends entirely on controlling temperature over time, and a modern muffle furnace's features—from programmable controllers to advanced insulation—are designed specifically to provide that critical control.

The Fundamental Goal of Sintering

Sintering is a foundational process in materials science, particularly for ceramics and metallurgy. Its success is defined by the quality of the final material's internal structure.

From Powder to Solid Mass

The core mechanism of sintering involves heating a material to a temperature below its melting point. At this high temperature, the atoms in the individual particles become mobile enough to diffuse across the boundaries of neighboring particles.

This atomic movement effectively "welds" the particles together, reducing the empty space (porosity) between them and causing the overall object to shrink and densify into a solid, coherent mass.

Why Microstructure is Critical

The goal is not just to create a solid object, but to create one with a specific, desirable microstructure. A well-executed sintering process results in a dense, uniform structure with high mechanical strength.

An improper process can lead to incomplete bonding, high porosity, or oversized grains, resulting in a weak and brittle final product.

How a Muffle Furnace Enables Precision Sintering

A muffle furnace is uniquely suited for sintering because it is engineered for control and stability. It provides the ideal environment by mastering several key variables.

The Principle of Controlled Heating

Modern muffle furnaces use electric resistance heating elements. When current passes through them, they generate predictable and consistent heat—a phenomenon known as Joule heating.

This allows for a clean heating process, free from the combustion byproducts that could contaminate the material being sintered.

Uniformity Through Design

To ensure the entire part sinters evenly, temperature uniformity is essential. High-quality muffle furnaces achieve this with features like:

- Multi-sided heating elements (e.g., on three sides) to distribute heat evenly throughout the chamber.

- Advanced insulation, such as vacuum-formed polycrystalline mullite fiber, which prevents heat loss and eliminates hot or cold spots.

Repeatability Through Programmable Control

The most critical feature for sintering is the ability to manage the temperature-time profile. Modern muffle furnaces use high-precision micro-computer controllers.

These controllers allow you to program a multi-stage process: a slow ramp-up to remove moisture, a hold at an intermediate temperature, a ramp to the final sintering temperature, a long hold (or "soak"), and a controlled cool-down. This makes the process scientific and repeatable.

Understanding the Trade-offs and Key Variables

Achieving a perfect sinter requires balancing several competing factors. The furnace gives you control, but you must know which variables to adjust.

The Temperature-Time Profile

This is the most important variable. The process is often divided into stages:

- Baking/Drying: A low-temperature stage (e.g., up to 600°C) to slowly drive off any residual moisture or binders without cracking the part.

- Semi-Sintering: An intermediate stage where particle necks begin to form, giving the part initial strength.

- Full Sintering: The final high-temperature stage where densification occurs. The exact temperature and duration determine the final density and grain size of the material.

Material Composition and Particle Size

The furnace provides the environment, but the material dictates the rules. The chemical composition and the size of the initial powder particles determine the required sintering temperature and time.

Generally, finer powders have more surface area and will sinter at lower temperatures and for shorter times than coarser powders.

The Role of Atmosphere

While many muffle furnaces operate in ambient air, the atmosphere inside the chamber is a key variable. Some furnaces include exhaust ports for processes like ashing or have systems for controlling the atmosphere.

The atmosphere can prevent oxidation in metals or react with the material to achieve specific properties, adding another layer of control.

Safety and Operational Demands

Sintering furnaces operate at extremely high temperatures for long periods and draw significant electrical current. Safety is paramount.

Look for features like automatic over-temperature protection, power cut-off when the door is opened, and thermocouple failure detection. These are not luxuries; they are essential for safe operation.

Making the Right Choice for Your Goal

To apply this knowledge effectively, align your process parameters with your primary objective.

- If your primary focus is maximum material density and strength: Pay closest attention to optimizing the final sintering temperature and hold time, as these directly govern the final microstructure.

- If your primary focus is process repeatability for production: Leverage the furnace's programmable controller to create, save, and execute a precise, multi-stage thermal profile for every run.

- If your primary focus is research with new materials: Start with conservative parameters (lower temperature, shorter hold time) and incrementally adjust them, carefully documenting the results to map out the material's behavior.

By understanding these principles, you transform the muffle furnace from a simple heat source into a precision tool for creating advanced materials with predictable, high-quality results.

Summary Table:

| Aspect | Key Insight |

|---|---|

| Process Goal | Transform powder into a solid, dense mass without melting. |

| Critical Factor | Precise control of the temperature-time profile. |

| Furnace Role | Provides a stable, uniform, and programmable high-temperature environment. |

| Key Variables | Temperature, hold time, material composition, and atmosphere. |

| Primary Applications | Ceramics manufacturing, powder metallurgy, materials research. |

Ready to achieve superior material density and repeatable results?

KINTEK's muffle furnaces are engineered with the precision and control essential for successful sintering. Whether you are developing new ceramics, manufacturing metal parts, or conducting advanced materials research, our lab equipment provides the stable, high-temperature environment your process demands.

Contact our experts today to find the perfect sintering solution for your laboratory's specific needs.

Visual Guide

Related Products

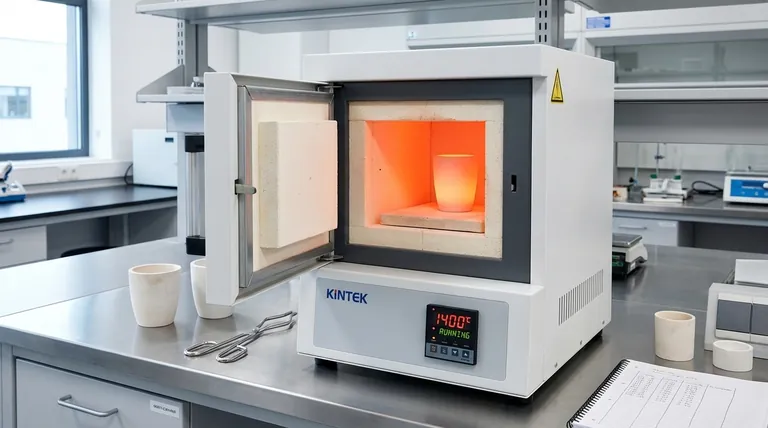

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is powder sintering process? A Guide to Solid-State Metal & Ceramic Fabrication

- What is the importance of ash determination in foods? A Key to Quality, Nutrition & Purity

- What is an ashing furnace? A Key Tool for Precise Inorganic Material Analysis

- What is the meaning of sintered? A Guide to Powder-Based Manufacturing

- Can a muffle furnace be used for calcination? Achieve Pure, Controlled Thermal Decomposition

- What role does a high-temperature calcination furnace play in the treatment of mesoporous titania? Unlock Full Potential

- Why is a high-temperature muffle furnace required for post-treatment after the hot-press sintering of LLZO?

- What is the minimum temperature for a muffle furnace? Understanding Its High-Tech Design