At its core, a sintering machine is specialized industrial equipment designed to compact and form a solid mass of material from a powder or other loose form. It achieves this by applying high heat and often pressure, but critically, it operates below the material's melting point, causing the particles to fuse together at their contact points.

Sintering is not a process of melting and casting; it is a method of atomic diffusion that bonds particles into a coherent, solid piece. This fundamental difference makes it an indispensable tool for working with high-melting-point materials and for creating components with precisely controlled properties like density and porosity.

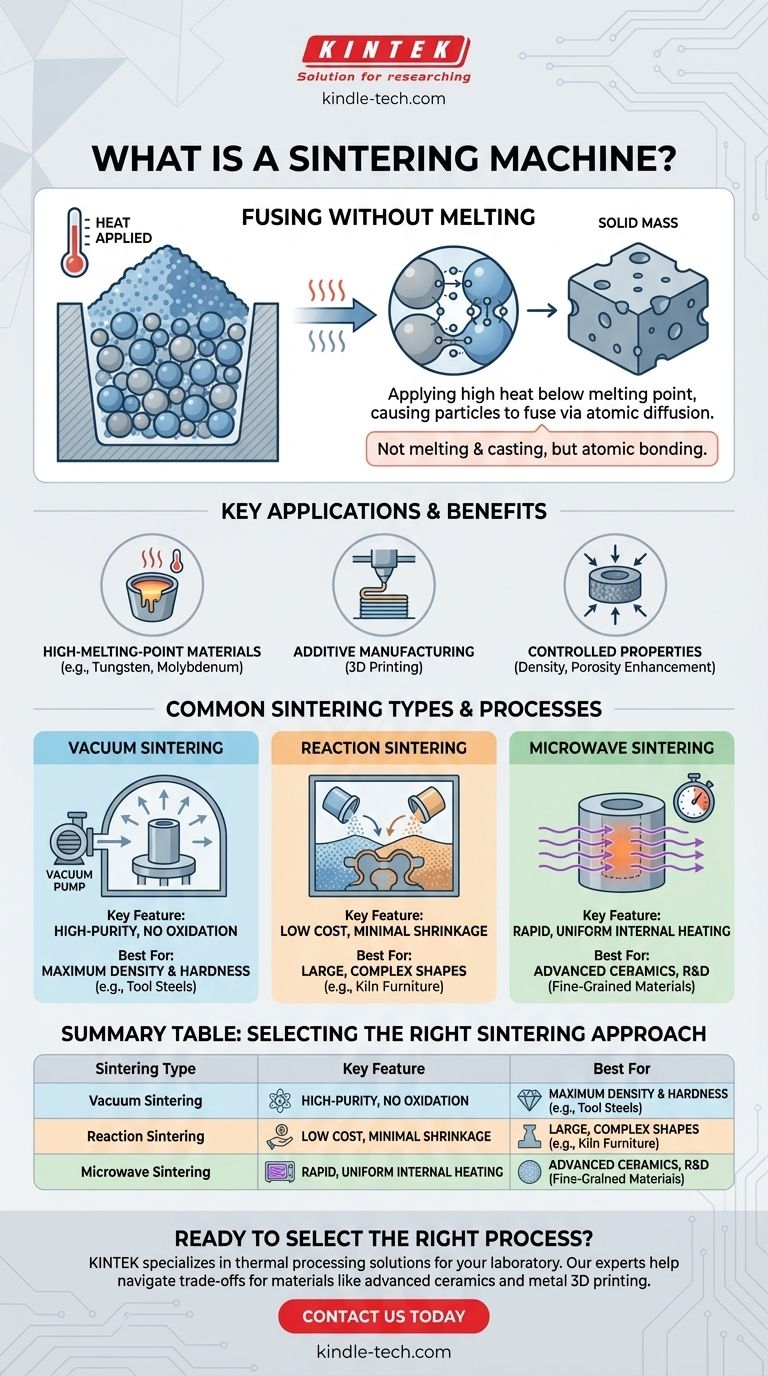

The Core Principle: Fusing Without Melting

How Sintering Works

The process begins with a powdered or loose aggregate material, which is often placed in a mold. The sintering machine then heats this material to a high temperature, exciting the atoms.

This thermal energy causes atoms to migrate across the boundaries of the individual particles, creating "necks" or bridges between them. Over time, these bridges grow, pulling the particles closer, reducing the empty space (porosity) between them, and forming a solid object.

Key Applications and Benefits

Sintering is not a one-size-fits-all solution; it is chosen for specific, powerful advantages.

It is essential for processing materials with extremely high melting points, such as tungsten and molybdenum, which would be difficult or economically unfeasible to melt and cast.

In additive manufacturing (3D printing), sintering is used to selectively fuse metal or ceramic powders layer by layer, enabling the creation of highly complex custom forms with greater control and lower energy use compared to melting. It also allows for the enhancement of material properties by reducing surface porosity.

Common Types of Sintering Machines and Processes

The term "sintering machine" encompasses several different technologies, each tailored for specific materials and outcomes.

Vacuum Sintering

This process takes place in a vacuum chamber. By removing air and other gases, the machine prevents oxidation and other unwanted chemical reactions during heating.

The primary benefit is the production of sintered parts with excellent densification, high purity, and superior hardness. The vacuum system actively removes gases released by the raw material, ensuring a stable and clean final product.

Reaction Sintering

In this method, a chemical reaction is intentionally triggered within the material during the heating process. This reaction aids in the formation and bonding of the final product.

Reaction sintering is valued for its low production cost and minimal shrinkage, making it ideal for preparing large or intricately shaped structures like high-temperature kiln components, heat exchangers, and optical mirrors.

Microwave Sintering

Unlike conventional furnaces that heat from the outside in, microwave sintering generates heat directly within the material itself. This leads to very rapid and more uniform heating.

This approach is extremely energy-efficient and fast, especially for small parts. It excels at preserving very fine grain structures in materials like advanced bioceramics, but its application can be limited by the material's ability to interact with microwaves and the relatively small batch sizes.

Understanding the Trade-offs

Choosing a sintering process requires understanding its inherent limitations and balancing competing priorities.

Material and Shape Constraints

Not all materials are suitable for every sintering method. Microwave sintering, for instance, requires powders with specific properties to effectively absorb microwave energy. The penetration depth of the microwaves can also limit the size of the part being processed.

Throughput vs. Precision

There is often a trade-off between production speed and the quality of the final part. Microwave sintering offers exceptional speed and property control for a single component but is not suited for mass production.

Conversely, other industrial methods are designed for high throughput, sometimes at the expense of the fine microstructural control offered by more advanced techniques.

Managing Impurities and Porosity

While vacuum sintering is excellent at producing high-purity parts, the equipment is complex and expensive. The goal of sintering is typically to reduce porosity, but achieving full densification can be challenging and costly.

Selecting the Right Sintering Approach

Your end goal determines which sintering technology is the most appropriate for the task.

- If your primary focus is high-purity and maximum density: Vacuum sintering is the superior choice for eliminating contaminants and achieving exceptional mechanical properties.

- If your primary focus is cost-effective production of large, complex shapes: Reaction sintering offers a distinct advantage due to its low shrinkage, allowing for near-net-shape manufacturing at lower temperatures.

- If your primary focus is rapid prototyping or developing advanced materials: Microwave sintering provides fast heating cycles and precise thermal control, making it ideal for research and producing fine-grained ceramics.

Understanding these core principles and variations empowers you to select the precise manufacturing process for your specific material and application.

Summary Table:

| Sintering Type | Key Feature | Best For |

|---|---|---|

| Vacuum Sintering | High-purity, no oxidation | Maximum density & hardness (e.g., tool steels) |

| Reaction Sintering | Low cost, minimal shrinkage | Large, complex shapes (e.g., kiln furniture) |

| Microwave Sintering | Rapid, uniform internal heating | Advanced ceramics, R&D, fine-grained materials |

Ready to Select the Right Sintering Process for Your Lab?

Choosing the correct sintering technology is critical for achieving the desired material properties, whether it's high purity, complex shapes, or rapid prototyping. KINTEK specializes in lab equipment and consumables, providing the precise thermal processing solutions your laboratory needs.

Our experts can help you navigate the trade-offs between vacuum, reaction, and microwave sintering to find the perfect match for your materials and applications, from advanced ceramics to metal 3D printing.

Contact us today to discuss your project requirements and discover how KINTEK's sintering solutions can enhance your research and development.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Touchscreen Automatic Vacuum Heat Press

People Also Ask

- Why is a vacuum hot-pressing furnace preferred for C_fiber/Si3N4 composites? Achieve High Density & Fiber Protection

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process