In the context of ceramics, the term "sintering pressing force" refers to the mechanical pressure applied during the high-temperature sintering process itself. While not a standard industry term, it correctly identifies the goal of using external force to aid in the consolidation and densification of ceramic particles, a technique formally known as hot pressing. This simultaneous application of heat and pressure accelerates the process of turning a loose powder into a dense, solid object.

The core idea is that heat provides the energy for ceramic particles to bond, while external pressure physically forces them together. This synergy overcomes natural barriers to densification, resulting in a stronger, less porous ceramic in less time and often at lower temperatures than with heat alone.

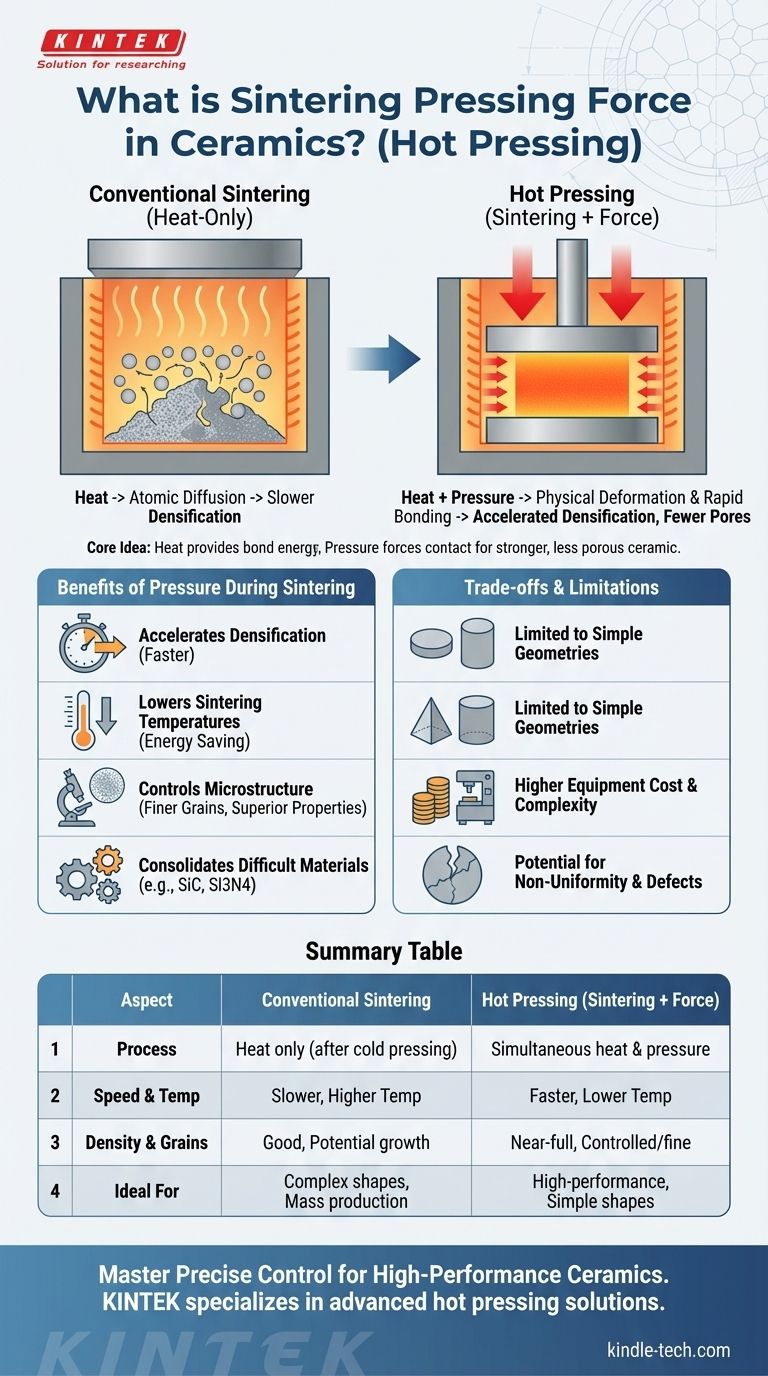

The Two Core Processes: Sintering and Pressing

To fully grasp the concept, it's essential to understand how pressing and sintering can work both separately and together.

Conventional Sintering (Heat-Only)

Conventional sintering is the process of heating a compacted ceramic powder (a "green body") to a high temperature, just below its melting point.

At this temperature, atoms diffuse across the boundaries of the particles, causing them to fuse together. This process reduces voids and increases the material's density and strength.

The Role of Pressing

Pressing is the application of mechanical force. It can happen before or during sintering.

When done before sintering, it's called cold pressing, which compacts the powder into a desired shape. When done during sintering, it is hot pressing.

The Synergy: Hot Pressing

Hot pressing is the technique your question describes. Heat and pressure are applied simultaneously.

The pressing force physically pushes particles into closer contact, deforming them slightly and dramatically increasing the rate at which they bond and pores are eliminated.

Why Apply Pressure During Sintering?

Adding an external pressing force is a deliberate engineering choice designed to achieve specific outcomes that heat alone cannot efficiently produce.

To Accelerate Densification

Pressure provides an additional driving force for densification. It mechanically closes the pores between particles, a task that would rely solely on slower atomic diffusion in conventional sintering.

This results in achieving near-full density much more quickly.

To Lower Sintering Temperatures

Because the force is doing much of the physical work, less thermal energy is required to achieve the same level of density.

Lowering the sintering temperature can save energy, reduce wear on furnace equipment, and prevent undesirable changes in the material's microstructure.

To Control Microstructure

The final properties of a ceramic are heavily dependent on its microstructure, particularly the size of its crystalline grains.

Hot pressing, with its lower temperatures and shorter times, helps prevent excessive grain growth. Smaller, more uniform grains typically lead to superior mechanical properties like hardness and fracture toughness.

To Consolidate Difficult Materials

Some advanced ceramics, like silicon nitride or silicon carbide, are extremely difficult to densify using only heat.

The addition of high pressure makes it possible to consolidate these high-performance materials into fully dense, usable forms.

Understanding the Trade-offs and Limitations

While powerful, applying pressure during sintering is not always the ideal solution. It introduces complexities and constraints.

Geometric Complexity

Hot pressing is generally limited to producing parts with simple geometries, such as discs, blocks, or cylinders. The uniaxial (one-direction) nature of the pressing makes it unsuitable for complex shapes.

Equipment Cost and Scale

The equipment required for hot pressing is significantly more expensive and complex than a standard sintering furnace. This often limits its use to high-value, high-performance applications.

Potential for Defects

If the pressure is not applied uniformly, it can introduce internal stresses or create density gradients within the ceramic part, potentially leading to cracks or failure points.

Making the Right Choice for Your Goal

Selecting the right manufacturing process depends entirely on the material and the desired outcome.

- If your primary focus is producing high-density, high-performance parts with fine grain structures: Combining pressure and heat via hot pressing is the superior method.

- If your primary focus is creating complex shapes or mass-producing items like tiles or insulators: A two-step process of cold pressing followed by conventional, pressureless sintering is far more practical and cost-effective.

- If your primary focus is understanding the fundamental mechanism: Remember that pressure acts as a powerful catalyst, forcing particles together to enhance the natural diffusion process driven by heat.

Ultimately, controlling pressure and temperature gives you direct control over the final density, strength, and performance of your ceramic material.

Summary Table:

| Aspect | Conventional Sintering | Hot Pressing (Sintering + Force) |

|---|---|---|

| Process | Heat only, after cold pressing | Simultaneous heat and uniaxial pressure |

| Densification Speed | Slower, relies on diffusion | Faster, pressure forces particle contact |

| Sintering Temperature | Higher | Lower |

| Final Density | Good | Near-full, superior |

| Grain Growth | More likely | Controlled, finer grains |

| Ideal For | Complex shapes, mass production | High-performance, simple geometries |

Ready to achieve superior ceramic performance?

KINTEK specializes in advanced lab equipment, including hot pressing solutions, to help you master the precise control of temperature and pressure required for high-density, high-strength ceramics. Whether you're developing advanced materials or optimizing your sintering process, our expertise and reliable equipment are here to support your success.

Contact our experts today to discuss how we can enhance your ceramic manufacturing capabilities!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes

- What are the advantages of using a vacuum hot press for CuCr50? Achieve Superior Density & Purity in Alloy Production

- What are the advantages of using a vacuum hot press sintering furnace? Achieve 99.1% Density in CuW30 Composites

- What advantages does hot pressing sintering equipment provide for NASICON? Achieve 100% Dense Solid Electrolyte Plates

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics