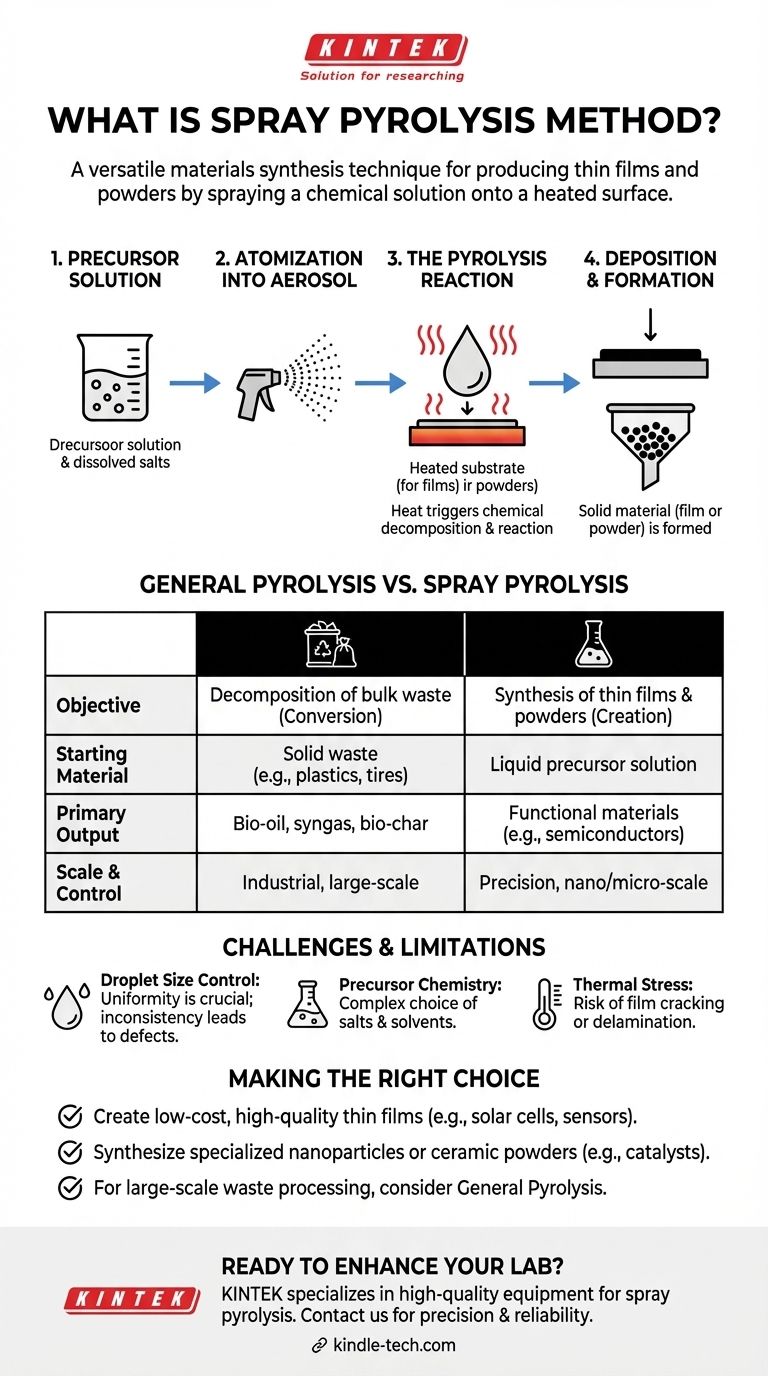

At its core, spray pyrolysis is a versatile materials synthesis technique used to produce thin films and powders. Unlike general pyrolysis which breaks down bulk waste, this method involves spraying a chemical solution (a precursor) onto a heated surface or into a heated zone, where the droplets undergo a thermal decomposition and reaction to form a solid material.

Spray pyrolysis is not about waste disposal; it is a precision manufacturing process. Its primary function is to transform a liquid chemical solution into a solid thin film or powder by using heat to trigger a chemical reaction within atomized droplets.

How Spray Pyrolysis Works: A Step-by-Step Breakdown

The elegance of spray pyrolysis lies in its straightforward, multi-stage process that offers significant control over the final material's properties.

Step 1: The Precursor Solution

The process begins with a precursor solution. This is a liquid, typically a solvent like water or alcohol, in which the desired chemical compounds (often metallic salts) are dissolved. The composition of this solution directly dictates the chemistry of the final solid material.

Step 2: Atomization into an Aerosol

This solution is then atomized—forced through a nozzle to create a fine mist or aerosol of tiny droplets. This step is critical, as the size and distribution of these droplets influence the uniformity and quality of the final product. Common atomizers use pressurized gas or ultrasonic vibrations.

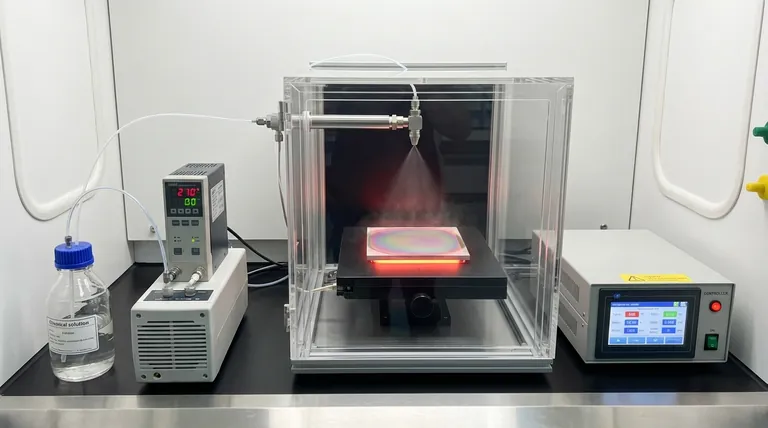

Step 3: The Pyrolysis Reaction

The aerosol is directed toward a heated substrate (for thin films) or into a heated reaction chamber (for powders). As a droplet approaches or lands on the hot surface, the solvent evaporates instantly. The intense heat then causes the precursor chemicals to pyrolyze, or thermally decompose and react, forming a new, stable solid compound.

Step 4: Deposition and Formation

For thin-film deposition, the decomposed particles form a solid layer that adheres to the substrate. By controlling the spray duration and solution concentration, one can precisely manage the film's thickness and morphology.

For powder synthesis, the solid particles formed in the heated chamber are carried by a gas flow and collected in a filter or cyclone separator.

General Pyrolysis vs. Spray Pyrolysis: A Critical Distinction

The provided references describe general bulk pyrolysis, which is fundamentally different from spray pyrolysis in its objective and mechanism. Understanding this difference is key.

The Starting Material

General pyrolysis processes bulk solid materials like plastic waste, tires, or biomass. Spray pyrolysis exclusively uses a liquid precursor solution.

The Core Objective

The primary goal of general pyrolysis is often decomposition and conversion, breaking down complex organic waste into valuable outputs like bio-oil, syngas, and bio-char.

In contrast, the goal of spray pyrolysis is synthesis and creation. It is a bottom-up manufacturing technique used to build highly specific materials like semiconductor films or ceramic nanoparticles.

The Scale and Control

General pyrolysis operates on a large, industrial scale focused on throughput. Spray pyrolysis is a precision technique that offers fine control over material properties like crystalline structure, thickness, and stoichiometry at the nano- or micro-scale.

Understanding the Trade-offs and Limitations

While powerful, spray pyrolysis is not without its challenges. Success depends on carefully managing several key variables.

Controlling Droplet Size

Achieving a uniform, defect-free thin film requires a consistent aerosol of fine droplets. Inconsistent or large droplets can lead to rough surfaces, pinholes, or a "cracked mud" morphology, compromising the material's performance.

Precursor Chemistry Complexity

The choice of precursor salts and solvents is not trivial. The chemicals must be soluble, decompose cleanly at the desired temperature, and not produce unwanted by-products. This can require significant research and development.

Thermal Stress

When depositing a film onto a substrate, the large temperature difference between the cool droplets and the hot surface can induce thermal stress. This can cause the film to crack or delaminate, especially for thicker layers.

Making the Right Choice for Your Goal

Selecting the right technique depends entirely on your end goal.

- If your primary focus is large-scale waste processing for fuel: You should investigate general pyrolysis systems like those described in the references, as spray pyrolysis is not designed for this application.

- If your primary focus is creating low-cost, high-quality thin films: Spray pyrolysis is an excellent choice for applications like solar cells, transparent conductive oxides (for touch screens), or gas sensors.

- If your primary focus is synthesizing specialized nanoparticles or ceramic powders: This method provides excellent control over particle composition and morphology for use in catalysts, pigments, or advanced materials.

Ultimately, spray pyrolysis is a powerful synthesis technique that transforms liquid chemistry into solid-state materials with precision and control.

Summary Table:

| Aspect | Spray Pyrolysis | General Pyrolysis |

|---|---|---|

| Objective | Synthesis of thin films & powders | Decomposition of bulk waste |

| Starting Material | Liquid precursor solution | Solid waste (plastic, biomass, tires) |

| Primary Output | Functional materials (e.g., semiconductors) | Bio-oil, syngas, bio-char |

| Scale & Control | Precision, nano/micro-scale | Industrial, large-scale |

Ready to enhance your lab's material synthesis capabilities? KINTEK specializes in providing high-quality lab equipment and consumables tailored for advanced techniques like spray pyrolysis. Whether you're developing thin films for solar cells or synthesizing specialized nanoparticles, our solutions ensure precision, reliability, and efficiency. Contact us today to explore how we can support your research and production goals!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What are the different types of reactors in plastic pyrolysis? Choose the Right System for Your Waste

- What are the emissions from pyrolysis of wood? Understanding VOC and Particulate Matter Risks

- What is the high temperature of a rotary furnace? Achieve Superior Uniform Heating for Powders & Granules

- What are the problems with biomass pyrolysis? High Costs & Technical Hurdles Explained

- What is the carbon content of pyrolysis oil? A Deep Dive into Its Composition and Uses

- What are the components of a rotary furnace? A Guide to Its Core Systems for Uniform Heating

- How much energy does a pyrolysis plant consume? Achieve Net Energy Producer Status

- What is the process of heating pyrolysis? A Guide to Oxygen-Free Thermal Decomposition