In the field of materials processing, Spark Plasma Sintering (SPS) is an advanced sintering technique that uses a combination of pulsed direct current (DC) and uniaxial pressure to consolidate powders into a dense solid. Unlike conventional furnaces that can take hours, SPS achieves this consolidation with extreme speed—often in just a few minutes—by passing current directly through the sample and its tooling, causing rapid internal heating.

The central challenge in sintering is achieving full density without causing unwanted grain growth, which can weaken the material. SPS solves this by using extreme heating rates to consolidate the material so quickly that the microscopic grains have no time to grow, preserving the fine-grained or nanostructured nature that gives advanced materials their superior properties.

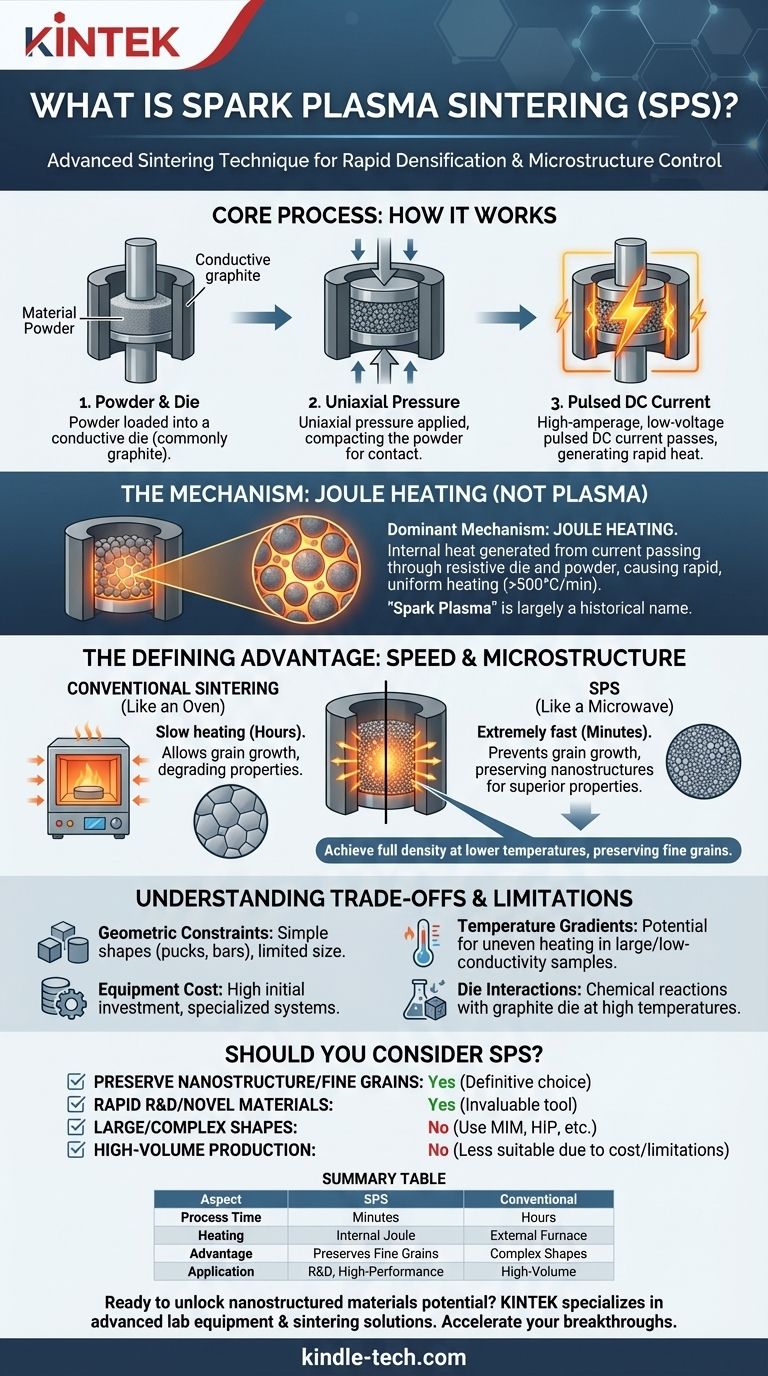

How Does Spark Plasma Sintering Work?

SPS, also known more accurately as Field Assisted Sintering Technique (FAST), is fundamentally different from conventional furnace heating. It is an active, rather than passive, process.

The Core Process: Powder, Pressure, and Current

A typical SPS cycle involves three key elements. First, the material powder is loaded into a conductive die, which is most commonly made of graphite.

Second, uniaxial pressure is applied to the powder through punches, compacting it and ensuring good particle-to-particle contact.

Third, a high-amperage, low-voltage pulsed DC current is passed through the punches and die. This current is the driving force behind the process's signature speed.

The Role of Joule Heating (and the "Spark Plasma" Myth)

The name "Spark Plasma Sintering" is largely historical. Early theories suggested that electric discharges or plasma formed between powder particles, cleaning their surfaces and aiding consolidation.

While localized plasma effects may play a minor role, it is now widely accepted that the dominant mechanism is Joule heating. This is the heat generated when an electric current passes through a resistive material—in this case, both the die and the powder compact itself (if it is conductive). This internal heat generation leads to incredibly fast and uniform heating rates, often exceeding 500°C per minute.

Key Control Parameters

An SPS operator has precise control over the process. The most critical parameters are the heating rate, the final sintering temperature, the hold time at that temperature, the applied pressure, and the atmospheric conditions (typically vacuum or an inert gas like argon).

The Defining Advantage: Speed and Microstructure Control

The primary reason to choose SPS over conventional methods like hot pressing or furnace sintering is its unparalleled ability to control the material's final microstructure.

Preventing Grain Growth

In conventional sintering, long exposure to high temperatures gives atoms time to diffuse, causing small grains to merge into larger ones. This process, known as grain growth, often degrades mechanical properties like hardness and strength.

Because an SPS cycle is so short (e.g., 5-10 minutes), it consolidates the powder into a dense solid before significant grain growth can occur. This makes it the premier technique for producing fully dense nanostructured materials.

Achieving High Density at Lower Temperatures

The combination of pressure and rapid, localized heating often allows materials to reach full density at temperatures hundreds of degrees lower than required in a conventional furnace. This further limits grain growth and prevents unwanted chemical reactions or phase transformations.

SPS vs. Conventional Sintering: An Analogy

Think of conventional furnace sintering as a conventional oven. It slowly heats the material from the outside-in.

In contrast, SPS is like a microwave oven. It generates heat directly within the material, leading to a much faster and more efficient process.

Understanding the Trade-offs and Limitations

Despite its advantages, SPS is not a universal solution. It comes with a specific set of constraints that make it unsuitable for certain applications.

Geometric and Size Constraints

The use of a rigid die means SPS is almost exclusively used to produce simple shapes, such as cylindrical "pucks" or small rectangular bars. Creating complex geometries is not feasible. Furthermore, the size of the final part is limited by the dimensions of the SPS machine's chamber and the available tooling.

Equipment Cost and Complexity

SPS systems are highly specialized and significantly more expensive than conventional furnaces or hot presses. They require a large power supply, a vacuum chamber, and a robust pressing frame, making the initial capital investment substantial.

Potential for Temperature Gradients

While often providing uniform heat, significant temperature gradients can develop, especially in large samples or materials with low thermal conductivity. The outside of the sample, being in direct contact with the hotter die, can reach a higher temperature than the core.

Material and Die Interactions

At very high temperatures, chemical reactions can occur between the sample material and the graphite die. This can lead to carbon contamination or the formation of carbides at the sample surface, which may require post-process machining to remove.

Should You Consider SPS for Your Project?

Choosing the right sintering method depends entirely on your end goal, budget, and material requirements.

- If your primary focus is preserving a nanostructure or fine grains: SPS is the definitive choice, as its speed is perfectly suited to preventing grain growth.

- If your primary focus is producing large or complex-shaped parts: Conventional methods like press-and-sinter, metal injection molding (MIM), or hot isostatic pressing (HIP) are far more practical and scalable.

- If your primary focus is rapid research and development of new materials: SPS is an invaluable tool for quickly screening novel compositions and difficult-to-sinter materials that would fail in a conventional furnace.

- If your primary focus is low-cost, high-volume production: The high cost and geometric limitations of SPS make it less suitable for mass production compared to established industrial methods.

Ultimately, Spark Plasma Sintering empowers engineers and scientists to create a new class of high-performance materials by conquering the timeless challenge of densification without degradation.

Summary Table:

| Aspect | Spark Plasma Sintering (SPS) | Conventional Sintering |

|---|---|---|

| Process Time | Minutes | Hours |

| Heating Mechanism | Internal Joule Heating | External Furnace Heating |

| Primary Advantage | Preserves fine grains/nanostructure | Suitable for complex shapes |

| Typical Application | R&D, high-performance materials | High-volume production |

Ready to unlock the potential of nanostructured materials in your lab?

KINTEK specializes in advanced lab equipment, including sintering solutions. Our expertise can help you achieve rapid densification and superior microstructure control for your research and development projects.

Contact our experts today to discuss how SPS technology can accelerate your materials science breakthroughs!

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are the fundamentals of spark plasma sintering process? Unlock Rapid, High-Performance Material Consolidation

- Why is precise temperature control required in vacuum hot pressing? Master Amorphous Powder Consolidation

- What unique physical conditions does a Hot Isostatic Press (HIP) provide? Optimize Li2MnSiO4/C Material Synthesis

- Why is a high vacuum required for hot pressing magnesium alloys? Achieve Superior Bonding at 1 x 10^-3 Pa

- What is hot isostatic pressing? Achieve Full Density and Superior Material Performance

- What is the process of hot-pressing sintering? Achieve Superior Density for High-Performance Materials

- What are the core functions of a graphite mold? Essential Roles in Vacuum Hot Pressing Sintering

- What are the advantages of using vacuum hot pressing for SiC/Al composites? Achieve Superior Microstructural Control