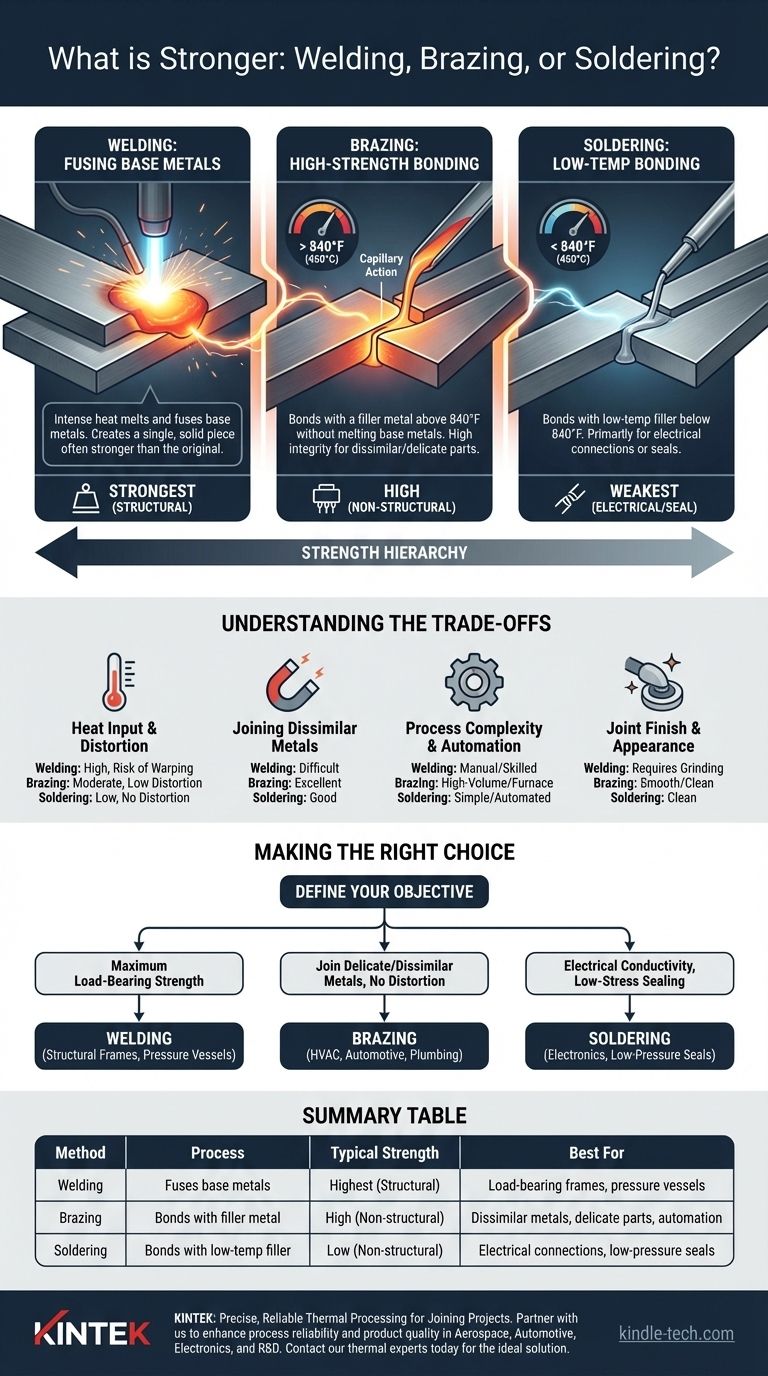

As a general rule, welding creates the strongest joint of the three methods. This is because welding is a fabrication process that melts and fuses the base metals together, often with a filler material, to form a single, solid piece. In contrast, both brazing and soldering join materials by melting a filler metal between them without melting the base metals themselves.

The critical insight is that "strength" is not a single property. While welding offers the highest absolute tensile and shear strength, brazing provides superior joint integrity when working with dissimilar metals or when needing to avoid the high heat and potential distortion caused by welding.

Understanding the Fundamental Difference: Fusing vs. Bonding

The source of strength for each method comes from its core mechanism. Understanding this difference is key to choosing the right process for your application.

Welding: Fusing Base Metals

Welding works by applying intense heat directly to the parent materials, causing them to melt and form a molten pool. A filler material is often added to this pool to create a robust connection.

As the pool cools and solidifies, the parent materials and filler are metallurgically fused into a single, continuous piece. This creates a homogenous joint that can be as strong as, or even stronger than, the original base metals.

Brazing and Soldering: Bonding with a Filler

Brazing and soldering are fundamentally adhesive processes. They use a filler metal with a lower melting point than the base materials being joined.

This filler is heated until it becomes liquid and is drawn into the tight-fitting gap between the parts via capillary action. It then solidifies, creating a strong bond that holds the components together without ever melting them. The only difference is temperature: brazing happens above 840°F (450°C), while soldering occurs below this point.

A Direct Comparison of Joint Strength

While context is everything, a direct strength hierarchy does exist among these three methods.

1. Welding: The Strongest Connection

Due to the fusion of the base metals, a properly executed weld is the undisputed strongest option. It is the standard for fabricating structural frames, pressure vessels, and any application where the joint must bear significant loads.

The weak point in a welded assembly is often not the weld itself but the heat-affected zone (HAZ)—the area of base metal surrounding the weld that was altered, but not melted, by the heat.

2. Brazing: High-Strength Bonding

Brazing produces a joint that is significantly stronger than soldering and sufficient for a vast range of engineering applications. While a brazed joint is typically not as strong as the parent metal, its strength is substantial.

The strength comes from both the adhesive properties of the filler alloy and the large surface area created by the capillary action. Brazing is common in HVAC, automotive, and plumbing systems where high joint integrity is required.

3. Soldering: The Weakest of the Three

Soldering creates the weakest joint and is not intended for load-bearing or structural applications. Its primary purpose is to form an electrical connection or a low-pressure seal.

The soft, low-temperature filler metals used in soldering are designed for conductivity and ease of use, not for mechanical strength.

Understanding the Trade-offs: Why "Strongest" Isn't Always "Best"

Choosing a joining method based on absolute strength alone is a common mistake. The "best" method is the one that best manages the trade-offs for a specific goal.

Heat Input and Distortion

Welding introduces an immense amount of localized heat, which can easily warp, distort, or crack thin or delicate components. The lower temperatures of brazing and soldering make them ideal for joining parts where dimensional stability is critical.

Joining Dissimilar Metals

Brazing excels at joining dissimilar metals, such as copper to steel or aluminum to brass. Since the base metals are not melted, there is no risk of creating brittle, incompatible alloys. Welding dissimilar metals is a highly complex process that is often impossible.

Process Complexity and Automation

Brazing can be performed in a furnace, making it highly suitable for high-volume production and automation. Welding often requires more direct, skilled manual labor for each joint, which can be slower and more costly at scale.

Joint Finish and Appearance

Brazed joints are naturally smooth and clean, often requiring no secondary finishing. Welded joints, by contrast, frequently have splatter and an uneven bead that must be ground down, adding an extra step to the manufacturing process.

Making the Right Choice for Your Goal

To select the correct process, you must first define your primary objective.

- If your primary focus is maximum load-bearing strength: Welding is the unparalleled choice for creating structural joints that are as strong as the base metals themselves.

- If your primary focus is joining delicate, thin, or dissimilar metals without distortion: Brazing offers a superior balance of high strength and low heat input, creating clean and reliable joints.

- If your primary focus is electrical conductivity or low-stress sealing: Soldering is the correct, cost-effective method designed specifically for these non-structural applications.

Choosing the right method requires matching the joint's properties—not just its absolute strength—to the unique demands of your project.

Summary Table:

| Method | Process | Typical Strength | Best For |

|---|---|---|---|

| Welding | Fuses base metals | Highest (Structural) | Load-bearing frames, pressure vessels |

| Brazing | Bonds with filler metal | High (Non-structural) | Dissimilar metals, delicate parts, automation |

| Soldering | Bonds with low-temp filler | Low (Non-structural) | Electrical connections, low-pressure seals |

Need precise, reliable thermal processing for your materials joining projects?

Whether you are developing brazing cycles for complex assemblies or require consistent heat treatment for welded components, KINTEK's advanced lab furnaces and ovens deliver the uniform temperature control essential for success.

We serve industries where joint integrity is critical, including:

- Aerospace & Automotive: For brazing and heat-treating high-performance components.

- Electronics Manufacturing: For precise soldering and annealing processes.

- Research & Development: For prototyping and testing new joining techniques and materials.

Partner with KINTEK to enhance your process reliability and product quality. Our equipment is engineered for accuracy and durability, helping you achieve stronger, more consistent results.

Contact our thermal experts today to discuss your specific application and find the ideal solution for your lab.

Visual Guide

Related Products

- Warm Isostatic Press for Solid State Battery Research

- CVD Diamond Dressing Tools for Precision Applications

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

People Also Ask

- What is hot isostatic pressing used for? Achieve Ultimate Material Integrity

- What does hot isostatic pressing do? Eliminate Internal Flaws for Superior Part Performance

- What does HIP process do? Eliminate Porosity for Superior Material Performance

- What are the advantages and limitations of hot isostatic pressing? Achieve Ultimate Material Integrity

- How does Hot Isostatic Pressing reduce porosity? Eliminate Internal Voids for Superior Material Density