The primary advantages of a hydraulic press over a mechanical press are superior control over force and speed, built-in overload protection, and lower initial and maintenance costs. Because they operate on the principle of fluid dynamics rather than a fixed mechanical linkage, hydraulic systems offer constant force throughout the entire press stroke, making them exceptionally versatile.

The core difference is flexibility versus speed. A hydraulic press provides constant, fully controllable force at any point in its stroke, making it ideal for complex forming. A mechanical press is faster but delivers its maximum force only at the very bottom of a fixed-length stroke.

The Foundation: How Hydraulics Achieve Superior Control

The advantages of a hydraulic press are a direct result of its fundamental operating principle. Unlike a mechanical press that relies on a flywheel and a fixed crankshaft, a hydraulic press uses fluid pressure to generate force.

Pascal's Law in Action

A hydraulic press works based on Pascal's Law, which states that pressure exerted on a confined fluid is transmitted equally in all directions.

A small amount of force applied to a small piston in a sealed hydraulic system generates immense pressure. This pressure is then transferred through the fluid to a much larger piston (the ram), multiplying the initial force significantly.

Full Tonnage, Anytime

This is the most critical operational advantage. A hydraulic press can deliver its full rated force at any point during the ram's stroke.

This capability is essential for applications like deep drawing, where consistent force is required over a long distance. Mechanical presses, in contrast, only achieve their maximum tonnage at the very bottom of their stroke.

Variable Speed and Stroke

The ram's speed, pressure, and stroke length are fully adjustable. Operators have precise control over the entire pressing cycle, including the ability to slow the ram down as it contacts the workpiece, reducing shock and improving part quality.

Key Operational and Financial Advantages

The simple and robust design of a hydraulic press translates into several tangible benefits for the operator and the business.

Built-in Overload Protection

Hydraulic presses have inherent overload protection. A pressure relief valve ensures that the press will never exert more force than its set limit.

If the press is overloaded, the valve simply opens, preventing catastrophic damage to the press or the tooling. A mechanical press, if overloaded, can crash, often resulting in costly repairs.

Lower Maintenance and Initial Cost

With significantly fewer moving parts compared to a mechanical press, there is less to wear out. This simpler design leads to a lower initial purchase price and reduced long-term maintenance costs.

Quieter Operation

The absence of a massive flywheel and complex gear systems makes hydraulic presses noticeably quieter than their mechanical counterparts. This contributes to a safer and more comfortable work environment.

Understanding the Trade-offs

While powerful and versatile, hydraulic presses are not the ideal solution for every application. Understanding their limitations is key to making an informed decision.

Speed and Repetition

For high-volume, repetitive operations like blanking or shallow stamping, mechanical presses are typically faster. Their fixed cycle allows for a much higher number of strokes per minute.

Manual vs. Automatic Systems

The efficiency of a hydraulic press depends heavily on its type. A simple manual press is affordable but can be labor-intensive and less precise for high-frequency use.

An automatic hydraulic press uses electricity to control the system, offering highly accurate, repeatable results that are ideal for production environments or busy labs.

Making the Right Choice for Your Application

Selecting the correct press requires matching the machine's strengths to your specific operational goals.

- If your primary focus is deep drawing or complex forming: A hydraulic press is the superior choice due to its constant force throughout the full stroke.

- If your primary focus is high-speed, repetitive stamping: A mechanical press will almost always provide greater throughput and efficiency.

- If your primary focus is tool safety and overload prevention: The inherent design of a hydraulic press offers unmatched protection against damage.

- If your primary focus is budget and operational flexibility: A hydraulic press generally offers a lower upfront cost and far greater control over the pressing process.

Ultimately, choosing a hydraulic press is a decision for versatility and control over raw, repetitive speed.

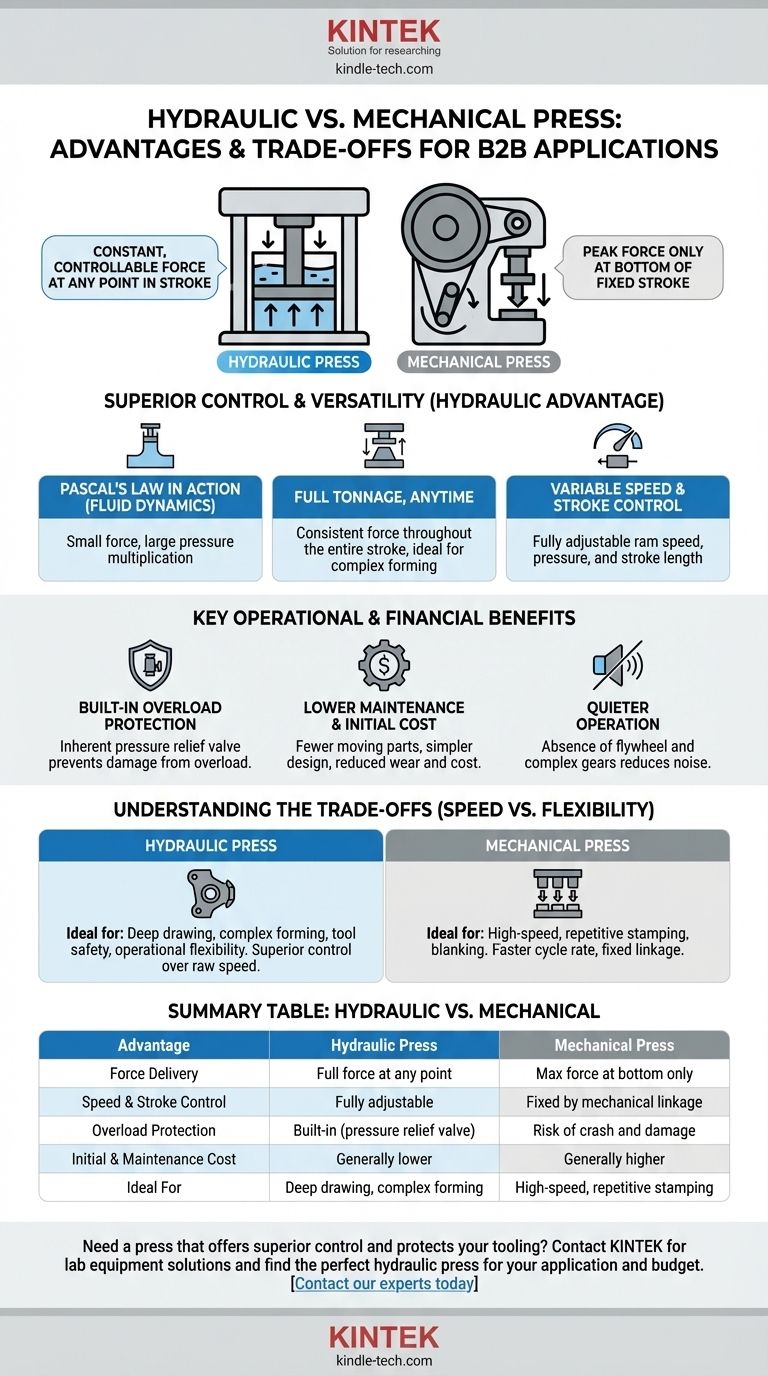

Summary Table:

| Advantage | Hydraulic Press | Mechanical Press |

|---|---|---|

| Force Delivery | Full force at any point in stroke | Max force only at bottom of stroke |

| Speed & Stroke Control | Fully adjustable | Fixed by mechanical linkage |

| Overload Protection | Built-in (pressure relief valve) | Risk of crash and damage |

| Initial & Maintenance Cost | Generally lower | Generally higher |

| Ideal For | Deep drawing, complex forming | High-speed, repetitive stamping |

Need a press that offers superior control and protects your tooling?

At KINTEK, we specialize in lab equipment and understand that the right hydraulic press can enhance your research, prototyping, or production work. Our presses provide the precise force control and built-in safety features your laboratory needs for complex forming tasks.

Contact our experts today to find the perfect hydraulic press solution for your specific application and budget.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Lab Heat Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!

- How does a laboratory hydraulic press contribute to the preparation of green pellets for nanostructured eutectic steel?

- Why is a laboratory hydraulic press used to compress powders into pellets? Enhance Solid-State Reaction Kinetics

- What is the hydraulic forging process? Master the Art of High-Strength Metal Forming

- Why is a laboratory hydraulic press required during the preparation of Ti3AlC2 precursor pellets?