The primary advantage of a sintered glass filter is its unique combination of highly uniform, controllable porosity with exceptional chemical inertness and mechanical strength. This is achieved by fusing glass particles together at high temperatures just below their melting point, creating a rigid, porous structure without the need for binders or adhesives that could contaminate the filtrate.

The key takeaway is that the manufacturing process—sintering—is directly responsible for the filter's superior performance. It creates a single, solid piece of porous glass, which provides a level of purity, precision, and durability that disposable or membrane-based filters cannot match.

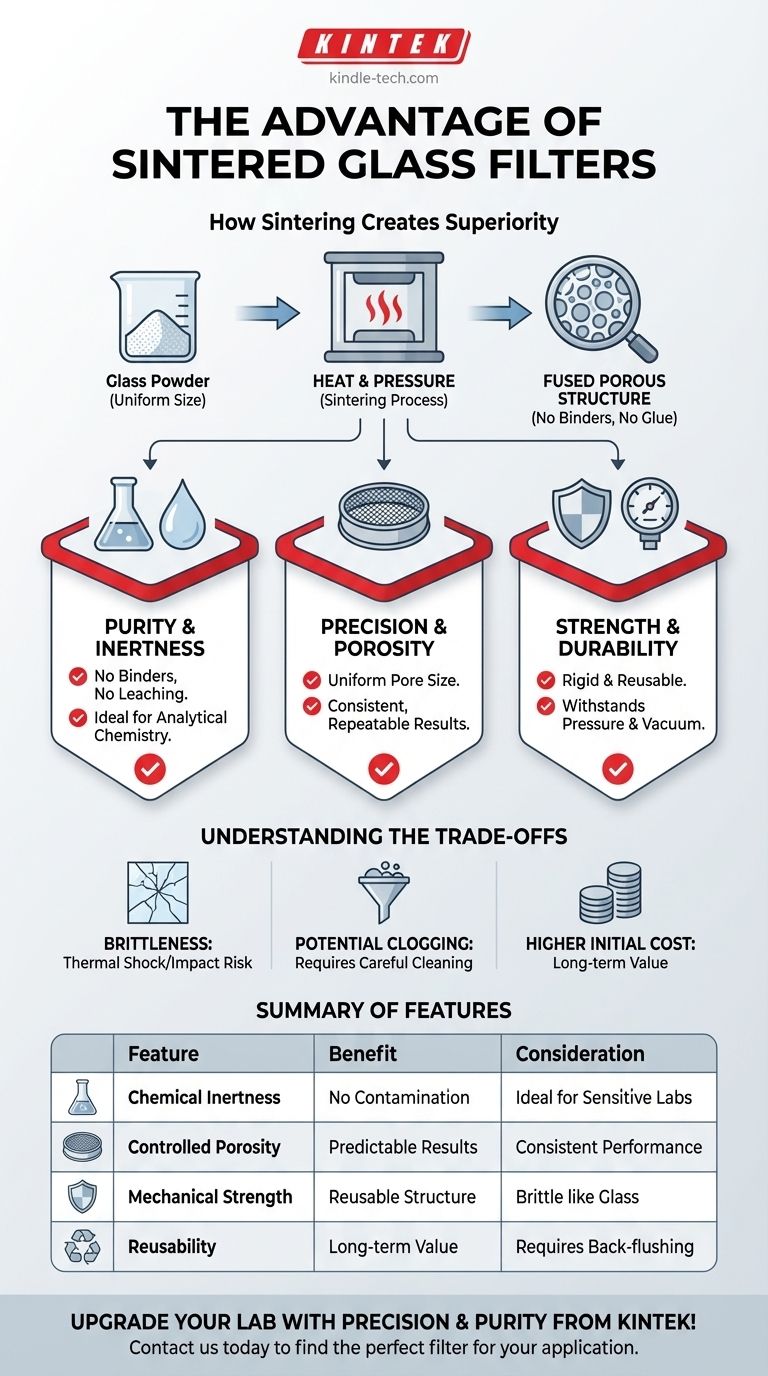

How Sintering Creates a Superior Filter

To understand the advantages, you must first understand the process. Sintering is not melting; it is a thermal treatment that uses heat and pressure to bond particles into a solid, coherent mass.

Think of packing snow into a hard snowball. You aren't melting the ice crystals, but you are forcing them to bond together, creating a much stronger structure. Sintering does the same with fine glass powder.

The Impact on Purity and Inertness

The sintering process itself is inherently clean. Because it relies on atomic diffusion between the glass particles, there is no need for binders, glues, or other additives that are common in other filter types.

This results in a filter medium that is as pure and chemically inert as the base glass material itself. For sensitive analytical chemistry, this is a non-negotiable advantage, as it prevents leaching or contamination of the sample.

The Impact on Porosity and Precision

The starting material for a sintered filter is a glass powder of a very specific and uniform grain size. This is the key to control.

By carefully selecting the particle size, manufacturers can produce filters with an extremely consistent and repeatable pore size. This ensures reliable and predictable filtration performance from one batch to the next, which is critical for standardized scientific procedures.

The Impact on Strength and Durability

The sintering process creates strong bonds between the glass particles, resulting in a single, rigid structure.

This gives the filter excellent mechanical strength, allowing it to withstand significant pressure differentials and vacuum without deforming or failing. The structure is robust and can be cleaned and reused many times, offering long-term value.

Understanding the Trade-offs

No solution is perfect. Being objective means acknowledging the limitations of even a superior technology.

Inherent Brittleness

While mechanically strong against pressure, the filter is still made of glass. Like any piece of laboratory glassware, it is brittle and susceptible to breakage from thermal shock (rapid temperature changes) or physical impact.

Potential for Clogging

The intricate, tortuous path through the sintered material is excellent for capturing particulates. However, this same structure can make it difficult to clean if it becomes deeply clogged with certain precipitates. It requires careful back-flushing or chemical cleaning.

Higher Initial Cost

Compared to disposable filter papers or simple membranes, sintered glass funnels and filters represent a higher upfront investment. Their value is realized through their reusability and long service life, but the initial purchase price is a factor.

Making the Right Choice for Your Goal

The decision to use a sintered glass filter should be based on the specific demands of your application.

- If your primary focus is analytical purity: The absence of binders and the inert nature of glass make it the definitive choice for applications where sample contamination is unacceptable.

- If your primary focus is repeatable, precise filtration: The uniform and controllable porosity ensures consistent results, making it ideal for standardized testing and quality control.

- If your primary focus is durability with aggressive chemicals or vacuum: The rigid, all-glass structure provides the mechanical and chemical resistance needed for harsh operating conditions.

Ultimately, the advantages of a sintered glass filter stem directly from how its monolithic, porous structure is formed.

Summary Table:

| Feature | Benefit | Consideration |

|---|---|---|

| Chemical Inertness | No binders or additives; prevents sample contamination. | Ideal for sensitive analytical chemistry. |

| Controlled Porosity | Uniform pore size for repeatable, predictable results. | Consistent performance in standardized procedures. |

| Mechanical Strength | Rigid structure withstands pressure and vacuum; reusable. | Brittle like glass; avoid thermal shock or impact. |

| Reusability | Long-term value through cleaning and repeated use. | Can clog with certain precipitates; requires careful cleaning. |

Upgrade your lab's filtration with precision and purity from KINTEK!

As a specialist in high-quality lab equipment, KINTEK provides sintered glass filters that deliver unmatched chemical inertness and precise pore control—ensuring your sensitive samples remain uncontaminated and your results are consistently reliable.

Our filters are designed for durability and reusability, offering long-term value for your laboratory. Whether you're in analytical chemistry, quality control, or research, KINTEK has the filtration solutions to meet your rigorous standards.

Contact us today to find the perfect sintered glass filter for your application and experience the KINTEK difference in performance and support!

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Buchner Funnel and Triangular Funnel

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Ceramic Evaporation Boat Set Alumina Crucible for Laboratory Use

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- How does the combination of PTFE tape and ceramic washers function in crevice corrosion modeling? Expert Analysis

- What are the process advantages of using PTFE channels in electrode installation ports? Ensure Precise Data Integrity

- How do Teflon (PTFE) baskets facilitate glass thin-film leaching? Enhance Accuracy with Chemical Inertness

- Why are PTFE or Teflon molds preferred for small-batch ceramic casting? Ensure Damage-Free Demolding & Purity

- Why is PTFE tape applied to ceramic crevice formers when assembling Alloy 22? Precision Tips for Corrosion Testing