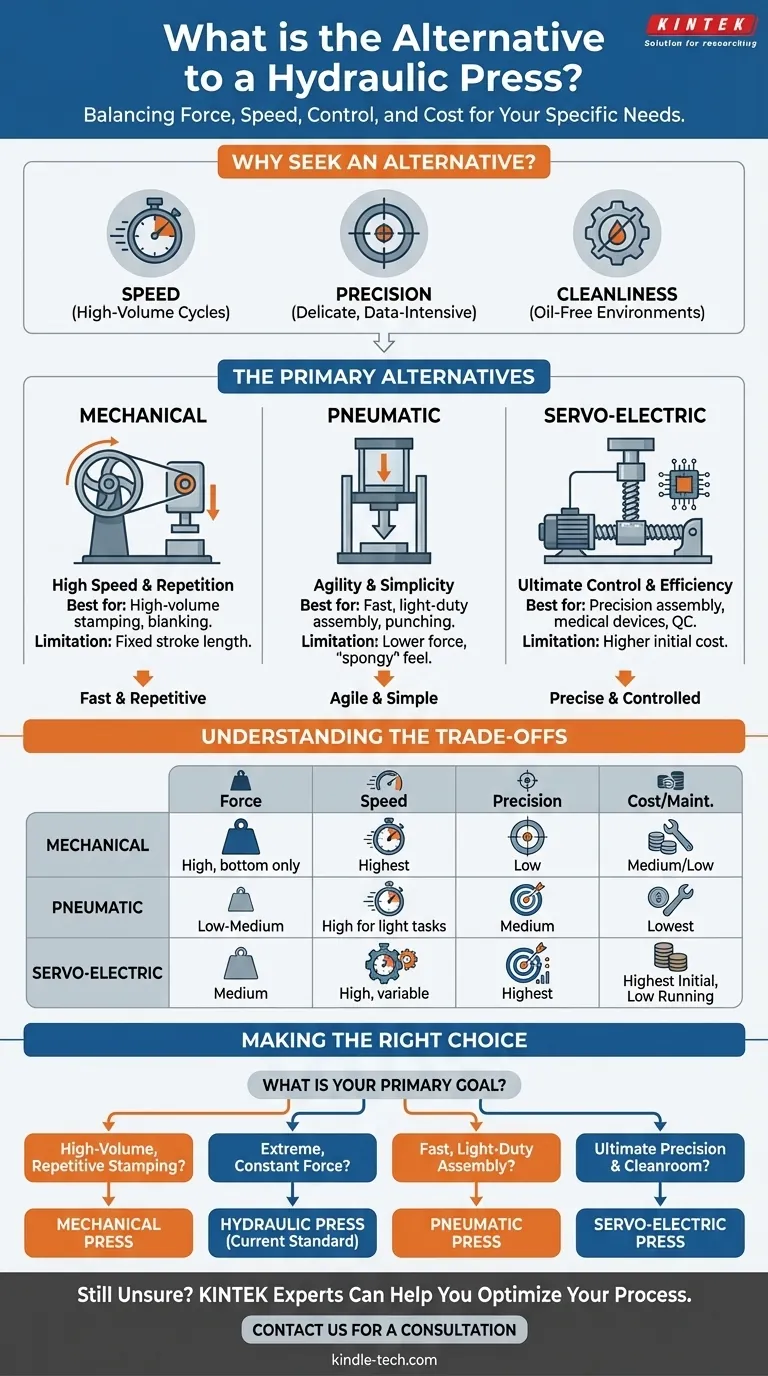

The primary alternatives to a hydraulic press are mechanical, pneumatic, and servo-electric presses. Each technology operates on a different principle and is best suited for specific applications where the raw, high-tonnage force of a hydraulic system may not be the optimal solution. The choice depends entirely on your specific requirements for speed, precision, and operational cost.

The core challenge isn't finding a machine that can apply force, but selecting the technology that best balances force, speed, control, and cost for your specific task. There is no single "best" alternative; there is only the right tool for the job.

Why Seek an Alternative to a Hydraulic Press?

While unparalleled in generating extreme force, hydraulic presses have inherent characteristics that make alternatives more suitable for certain tasks. Understanding these helps clarify why another type of press might be a better fit.

The Need for Speed

Hydraulic systems move fluid to build pressure, which can be slower than the direct action of a mechanical or pneumatic press. For high-volume, repetitive tasks like stamping, this cycle time is a critical factor.

The Demand for Precision

While modern hydraulics offer excellent control, servo-electric presses provide superior, programmable control over every aspect of the stroke—position, speed, and force. This is crucial for delicate assembly or data-intensive processes.

Concerns About Maintenance and Cleanliness

Hydraulic systems rely on oil, which presents a risk of leaks. In cleanroom environments, such as medical or electronics manufacturing, oil-free alternatives like pneumatic or servo-electric presses are often required.

The Primary Alternatives Explained

Each alternative leverages a different mechanism to generate force, resulting in a unique performance profile.

Mechanical Presses: High Speed and Repetition

A mechanical press uses a motor to spin a flywheel, which stores kinetic energy. When engaged, a clutch and crank system converts this rotational energy into the linear motion of the ram.

Their primary advantage is speed. They are capable of extremely high cycle rates, making them the standard for high-volume metal stamping, blanking, and coining operations.

The main limitation is a fixed stroke length. The force they deliver also varies throughout the stroke, peaking near the bottom, which offers less control than a hydraulic press.

Pneumatic Presses: Agility and Simplicity

Pneumatic presses, often called air presses, use compressed air to drive a piston and apply force. They are simple, relatively inexpensive, and easy to maintain.

They excel at applications requiring high speed for light-to-medium force, such as punching, crimping, and assembling small parts. They can cycle very quickly and are clean to operate.

Their fundamental limitation is force generation. Because air is compressible, they cannot achieve the high tonnages of hydraulic systems and can have a "spongy" feel at the point of contact.

Servo-Electric Presses: Ultimate Control and Efficiency

Servo-electric presses represent the most modern alternative. They use a high-torque servo motor connected to a ball screw or roller screw to directly control the ram's movement with extreme precision.

Their defining feature is programmability. Every parameter of the stroke—force, position, speed, and dwell time—can be precisely controlled and monitored. This makes them ideal for precision assembly, medical device manufacturing, and quality control.

They are also highly energy-efficient, consuming power only during the stroke. The main barrier is typically a higher initial investment cost compared to other press types.

Understanding the Trade-offs

Choosing the right press technology is a matter of prioritizing competing factors. No single press excels in all categories.

Force Generation

A hydraulic press is the undisputed leader for applications requiring extremely high tonnage. Mechanical presses offer high force but only at the very bottom of the stroke. Pneumatic and servo-electric presses are generally used for lower-to-medium force applications.

Cycle Speed

For pure repetitive speed in high-volume production, the mechanical press is king. For rapid, light-duty tasks, a pneumatic press is often the fastest and most cost-effective choice.

Control and Precision

The servo-electric press offers unparalleled, programmable control over the entire process. Hydraulic presses offer very good force control, while mechanical presses offer the least flexibility.

Operating Cost and Maintenance

Pneumatic and screw presses are typically the least expensive to purchase and maintain. Servo-electric presses have a higher upfront cost but offer significant long-term savings through energy efficiency and low maintenance, as there are no fluids to leak or replace.

Making the Right Choice for Your Goal

Your application's primary goal should guide your decision.

- If your primary focus is high-volume, repetitive stamping: A mechanical press offers the unmatched cycle speed required for mass production.

- If your primary focus is extreme, constant force for deep drawing or crushing: A hydraulic press remains the superior and most cost-effective technology.

- If your primary focus is fast, light-duty assembly or punching: A pneumatic press provides a simple, clean, and agile solution.

- If your primary focus is ultimate precision, data collection, and cleanroom operation: A servo-electric press is the definitive choice, despite the higher initial cost.

Ultimately, selecting the correct press technology requires a clear understanding of your specific operational needs and priorities.

Summary Table:

| Alternative Press Type | Key Advantage | Best For | Main Limitation |

|---|---|---|---|

| Mechanical Press | High Speed & Repetition | High-volume metal stamping, blanking | Fixed stroke length, less control |

| Pneumatic Press | Agility & Simplicity | Fast, light-duty assembly, punching | Lower force, 'spongy' feel |

| Servo-Electric Press | Ultimate Control & Precision | Precision assembly, medical devices, QC | Higher initial investment |

Still Unsure Which Press is Right for Your Lab?

Choosing the right press technology is critical for your productivity and results. The experts at KINTEK specialize in lab equipment and consumables, and we can help you navigate these trade-offs to find the perfect solution for your specific application—whether you prioritize speed, precision, or a clean operating environment.

Contact us today for a personalized consultation and let us help you optimize your process.

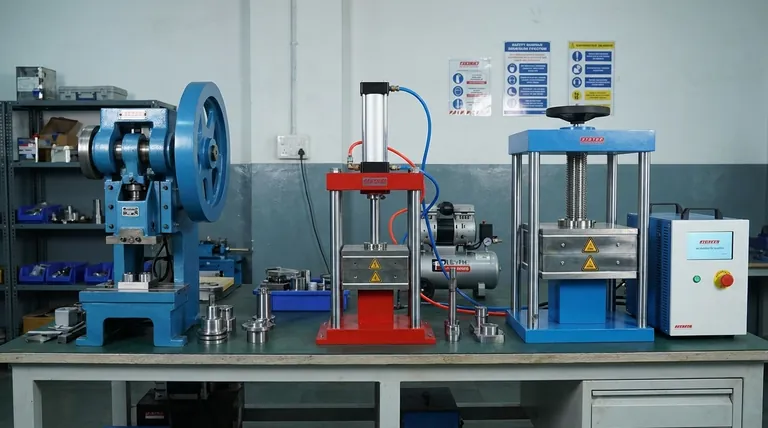

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Double Plate Heating Press Mold for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.